Abstract

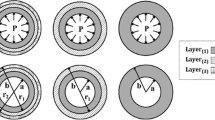

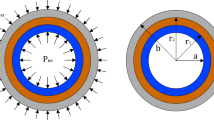

Although analysis/design of multilayer assemblies has been always an active field of research, works on the optimal design of rotating multilayer composite tubes are very limited. This paper addresses the design optimization of rotating multilayer composite tubes under internal heating and pressure. For determining the structural responses, analytical solutions are provided based on different boundary conditions. The automated selection of optimal material as well as thickness optimization of pressurized multilayer assemblies is carried out under different angular speed and internal heating conditions using a metaheuristic algorithm. The corresponding optimum design for each angular speed as well as internal heating condition is sought, and the numerical results are discussed. The study provides general guidelines for conceptual design of rotating multilayer composite tubes subjected to internal heating and pressure.

Similar content being viewed by others

References

Akbulut M, Sarac A, Ertas AH (2020) An investigation of non-linear optimization methods on composite structures under vibration and buckling loads. Adv Comput Des 5(3):209–231

Akis T, Eraslan AN (2005) Yielding of long concentric tubes under radial pressure based on von Mises criterion. J Fac Eng Arch Gazi Univ 20:365–372 (In Turkish)

Alkayem NF, Cao M, Zhang Y, Bayat M, Su Z (2018) Structural damage detection using finite element model updating with evolutionary algorithms: a survey. Neural Comput Appl 30:389–411

Apatay T, Mack W (2015) On the optimum design of rotating two-layered composite tubes subject to internal heating or pressure. Forsch Ing 79:109–122

Colorni A, Dorigo M, Maniezzo V (1991) Distributed optimization by ant colony. In: Proceedings of the first European conference on artificial life, USA, pp 134–142

Eraslan AN, Akis T (2005) Yielding of two-layer shrink-fitted composite tubes subject to radial pressure. Forsch Ing 69:187–196

Eraslan AN, Sener E, Argeso H (2003) Stress distributions in energy generating two-layer tubes subjected to free and radially constrained boundary conditions. Int J Mech Sci 45:469–496

Erbatur F, Al-Hussainy MM (1992) Optimum design of frames. Comput Struct 45:887–891

Erol OK, Eksin I (2006) A new optimization method: big bang-big crunch. Adv Eng Softw 37:106–111

Gen M, Zhang W, Lin L, Yun YS (2017) Recent advances in hybrid evolutionary algorithms for multi-objective manufacturing scheduling. Comput Ind Eng 112:616–633

Goldberg DE, Samtani MP (1986) Engineering optimization via genetic algorithm. In: Proceeding of the ninth conference on electronic computation. ASCE, pp 471–82

Hasançebi O, Kazemzadeh Azad S (2015) Adaptive dimensional search: a new metaheuristic algorithm for discrete truss sizing optimization. Comput Struct 154:1–16

Jahed H, Farshi B, Karimi M (2006) Optimum autofrettage and shrink-fit combination in multi-layer cylinders. Trans ASME J Press Vessel Technol 128:196–200

Kazemzadeh Azad S (2019) Monitored convergence curve: a new framework for metaheuristic structural optimization algorithms. Struct Multidiscip Optim 60(2):481–499

Kazemzadeh Azad S, Akış T (2018) Automated selection of optimal material for pressurized multi-layer composite tubes based on an evolutionary approach. Neural Comput Appl 29:405–416

Kazemzadeh Azad S, Akış T (2019) A study of shrink-fitting for optimal design of multi-layer composite tubes subjected to internal and external pressure. IJST Trans Mech Eng 43:451–467

Kennedy J, Eberhart R (1995) Particle swarm optimization. In: IEEE international conference on neural networks. IEEE Press, pp 1942–1948

Koç Ç (2017) An evolutionary algorithm for supply chain network design with assembly line balancing. Neural Comput Appl 28:3183–3195

Lee KS, Geem ZW (2004) A new structural optimization method based on the harmony search algorithm. Comput Struct 82:781–798

Lee ZY, Chen CK, Hung CI (2001) Transient thermal stress analysis of multilayered hollow cylinder. Acta Mech 151:75–88

MATLAB (2019) version 9.7 (R2019b) The MathWorks Inc., Natick, Massachusetts

Miraje AA, Patil SA (2012) Optimum thickness of three-layer shrink fitted compound cylinder for uniform stress distribution. Int J Adv Eng Technol 3(2):591–605

Noda N, Hetnarski RB, Tanigawa Y (2003) Thermal stresses, 2nd edn. Taylor and Francis, New York

Ootao Y, Tanigawa Y, Fukuda T (1991) Axisymmetric transient thermal stress analysis of a multilayered composite hollow cylinder. J Therm Stress 14:201–213

Rama Mohan Rao A, Lakshmi K, Ganesan K (2013) Structural system identification using quantum behaved particle swarm optimisation algorithm. SDHM Struct Durab Health Monit 9(2):99–128

Saka MP (1991) Optimum design of steel frames with stability constraints. Comput Struct 41:1365–1377

Sharifi M, Arghavani J, Hematiyan MR (2012) An analytical solution for optimum design of shrink-fit multi-layer compound cylinders. Int J Appl Mech 4:1250043

Sharifi M, Arghavani J, Hematiyan MR (2014) Optimum arrangement of layers in multi-layer compound cylinders. Int J Appl Mech 6:1450057

Tabak EI, Wright PM (1981) Optimality criteria method for building frames. J Struct Div ASCE 107:1327–1342

Timoshenko SP, Goodier JN (1970) Theory of elasticity, 3rd edn. McGraw-Hill, New York

Tutuncu N (1995) Radial stresses in composite thick-walled shafts. J Appl Mech 62:547–549

Tzeng JT (2002) Viscoelastic analysis of composite cylinders subjected to rotation. J Compos Mater 36:229–239

Zhou SS, Gao XL, Griffith GW (2012) Stress analysis and structural optimization of a three-layer composite cladding tube under thermo-mechanical loads. J Eng Mater Technol ASME 134(3):031001

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

Kazemzadeh Azad, S., Akış, T. Metaheuristic Optimization of Rotating Multilayer Composite Tubes Under Internal Heating and Pressure. Iran J Sci Technol Trans Mech Eng 46, 253–273 (2022). https://doi.org/10.1007/s40997-020-00421-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-020-00421-1