Abstract

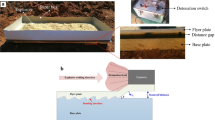

Dynamic bend angle (β) is an important parameter that should satisfy the range defined by the weldability window for successful joining in the explosive welding process. In this manuscript, we studied the dynamic bend angle (β) for the newly developed low velocity of detonation explosive welding (LVEW) process theoretically and then experimentally with the help of flash X-ray radiography (FXR) technique. The FXR system captured the real-time image of the event where proper explosive welding process with clear flight shape and appropriate collision bend angle was observed. The FXR results were in good agreement with numerically calculated β values and demonstrated the suitability of LVEW process for joining of dissimilar metal plates. This was further justified by phased array-based ultrasonic testing (PAUT) results where complete bonding area with slight non-bonded area was observed across the edges of the welded metal plate.

Similar content being viewed by others

References

Ramudu, B.V., C.J. Reddy, and V. Madhu, Flash X-ray radiography technique to study the high velocity impact of soft projectile on E-glass/epoxy composite material. Defence Technology, 2019. 15(2): p. 216-226.

Helberg, P., K. Michael, and K. Thoma. Flash x-ray computed tomography for applications in high-speed dynamics. in 9th European Conf. Non-Destructive Testing, Berlin. 2006.

Mizusako, F., et al., Flash x-ray radiography using imaging plates for the observation of hypervelocity objects. Review of scientific instruments, 2005. 76(2): p. 025102.

Strassburger, E., et al., Flash X-ray cinematography analysis of dwell and penetration of small caliber projectiles with three types of SiC ceramics. Defence Technology, 2016. 12(3): p. 277-283.

Tamura, H., Y. Tanaka, and F. Saito, Quantitative analysis of debris from SiC-fiber-reinforced aluminum-alloy targets impacted by spherical projectiles. International journal of impact engineering, 2011. 38(8-9): p. 686-696.

Thoma, K., P. Helberg, and E. Strassburger. Real time-resolved flash X-ray cinematographic investigation of interface defeat and numerical simulation validation. in 23rdIntn’l Symposium on Ballistics, Tarragona, Spain, ADPA. 2007.

Wang, X., et al., Numerical study of the mechanism of explosive/impact welding using smoothed particle hydrodynamics method. Materials & Design, 2012. 35: p. 210-219.

Mousavi, S.A. and S. Al-Hassani, Finite element simulation of explosively driven plate impact with application to explosive welding. Materials & Design, 2008. 29(1): p. 1-19.

Mousavi, A.A., S. Burley, and S. Al-Hassani, Simulation of explosive welding using the Williamsburg equation of state to model low detonation velocity explosives. International journal of impact engineering, 2005. 31(6): p. 719-734.

Sherpa, B.B., et al., Study of the Explosive Welding Process and Applications. Advances in Applied Physical and Chemical Sciences-A Sustainable Approach, 2014: p. 33–39.

Sherpa, B.B., et al., Neuro-Fuzzy Technique for Micro-hardness Evaluation of Explosive Welded Joints. Transactions of the Indian Institute of Metals, 2020. 73(5): p. 1287-1299.

Zhou, Q., J. Feng, and P. Chen, Numerical and experimental studies on the explosive welding of tungsten foil to copper. Materials, 2017. 10(9): p. 984.

Crossland, B. and A. Bahrani, Fundamentals, of explosive welding. Contemporary Physics, 1968. 9(1): p. 71-87.

Lysak, V. and S. Kuzmin, Lower boundary in metal explosive welding. Evolution of ideas. Journal of Materials Processing Technology, 2012. 212: p. 150–156.

Sherpa, B.B., et al., Low Velocity of Detonation Explosive Welding (LVEW) Process for Metal Joining. Propellants, Explosives, Pyrotechnics, 2020. 45(10): p. 1554-1565.

Abrahamson, G.R., Permanent periodic surface deformations due to a traveling jet. Journal of Applied Mechanics, 1961. 28(4): p. 519-528.

Pugalendhi, P. and D. Veerarju. Use of Phased Array Ultrasonic Testing (PAUT) & Time Of Flight Diffraction (TOFD) in Lieu of Radiography Testing on ASME U Stamp Pressure Vessel fabrication Projects. in Singapore International NDT Conference & Exhibiton. 2013.

Caravaca, D., C. Bird, and D. Kleiner, Ultrasonic phased array inspection of electrofusion joints in polyethylene pipes. Insight-Non-Destructive Testing and Condition Monitoring, 2007. 49(2): p. 83-86.

Tabatabaee Ghomi, M., Impact wave process modeling and optimization in high energy rate explosive welding. 2009, Mälardalens högskola.

Andreevskikh, L.A., et al., Explosive mixture for explosive welding of thin foils. Propellants, Explosives, Pyrotechnics, 2011. 36(1): p. 48-50.

Ribeiro, J., R. Mendes, and A. Loureiro. Review of the weldability window concept and equations for explosive welding. in Journal of Physics: Conference Series. 2014. IOP Publishing.

Cowan, G., O. Bergmann, and A. Holtzman, Mechanism of bond zone wave formation in explosion-clad metals. Metallurgical and Materials Transactions B, 1971. 2(11): p. 3145-3155.

Deribas, A., V. Simonov, and I. Zakcharenko. Investigation of explosive welding parameters for arbitrary combinations of metals and alloys. in Proc. 5th Int. Conf. on High Energy Rate Fabrication. 1975. University of Denver Denver, CO.

Walsh, J., R. Shreffler, and F. Willig, Limiting conditions for jet formation in high velocity collisions. Journal of Applied Physics, 1953. 24(3): p. 349-359.

Deribas, A. and I. Zakharenko, Surface effects with oblique collisions between metallic plates. Combustion, Explosion and Shock Waves, 1974. 10(3): p. 358-367.

Wittman, R. Use of explosive energy in manufacturing metallic materials of new properties. in Proceedings of the Second International Symposium, Marianski Lazne, Czechoslovakia. 1973.

Habib, M.A., et al., Cladding of titanium and magnesium alloy plates using energy-controlled underwater three layer explosive welding. Journal of Materials Processing Technology, 2015. 217: p. 310-316.

Huggett, D., et al., Phased array ultrasonic testing for post-weld and online detection of friction stir welding defects. Research in Nondestructive Evaluation, 2017. 28(4): p. 187-210.

Sherpa, B.B., et al. Interface Study of Explosive Welded AL-Steel Joint Using Ultrasonic Phased Array Technique. in 31st International Symposium on Ballistics. 2019.

Akbari-Mousavi, S., L. Barrett, and S. Al-Hassani, Explosive welding of metal plates. Journal of materials processing technology, 2008. 202(1-3): p. 224-239.

Rao, N.V., et al., Influence of hot rolling and heat treatment on structure and properties of HSLA steel explosively clad with austenitic stainless steel. Materials Science and Technology, 2009. 25(11): p. 1387-1396.

Mastanaiah, P., et al., An investigation on microstructures and mechanical properties of explosive cladded C103 niobium alloy over C263 nimonic alloy. Journal of Materials Processing Technology, 2014. 214(11): p. 2316-2324.

Acknowledgement

The support from the Terminal Ballistics Research Laboratory is highly acknowledged. Authors are very thankful to Dr Manjit Singh, Director, TBRL, Sec 30, Chandigarh, all the scientists of Zone-IV, EED, M.T., and Workshop of TBRL for their valuable support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sherpa, B.B., Kumar, P.D., Upadhyay, A. et al. Experimental and theoretical study of dynamic bend angle in the explosive welding process. Trans Indian Inst Met 74, 511–519 (2021). https://doi.org/10.1007/s12666-021-02189-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02189-7