Abstract

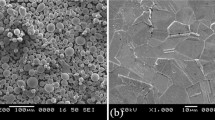

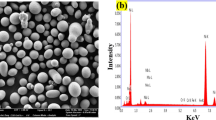

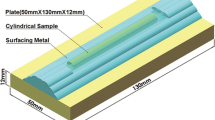

In recent years, microwave welding has received attention for joining of similar and dissimilar metals due to its major advantages like volumetric heating, selective heating of target materials, energy saving and sustainability. In the present work, the microstructural characteristics and mechanical properties of Inconel-625-welded joints developed through microwave hybrid heating and those produced by TIG welding have been compared. Welding through microwave hybrid heating (MHH) was carried out using Inconel-625 interface filler powder of 50 μm size, while TIG welding was carried out using ERNiCrMo-3 filler wire of 2.5 mm diameter which had a composition similar to that of Inconel-625 alloy. The welded samples were characterized in terms of microstructural observations and tensile and microhardness properties. The study reveals that the joining of bulk metals through MHH has potential in manufacturing industries in the near future. TIG-welded joints exhibit superior strength compared to MHH joints because of fine grain structure, lower amount of segregation in the weld zone and also smaller width of the weld zone in joints developed through MHH. The hardness in the weld zone of welded joints in both the cases is observed to be almost the same. Use of a finer interface filler of 20–25 μm particle size may further contribute to improving the mechanical properties of the joints developed through MHH. Furthermore, the use of industrial microwave furnace may improve the strength of MHH-welded joints as the process may be integrated with real-time temperature measurement of the joint zone so as to achieve better control over the process.

Similar content being viewed by others

References

DuPont, J.N., Lippold, J.C. and Kiser, S.D. (2009). “Welding Metallurgy and Weldability of Nickel-Base Alloys.” John Wiley & Sons, Inc.: USA.

Badiger R I, Narendranath S and Srinath M S (2015). J. Manuf. Processes 18, 117-123.

DuPont, J.N., Notis, M.R., Marder, A.R., Robino, C.V. and Michael, J. R. (1998). “Solidification of Nb-bearing superalloys: Part I. Reaction sequences.” Metall. Mater. Trans. A, 29(11), 2785-2796.

Lee, H.T., Jeng, S.L., Yen, C.H.and Kuo, T.Y. (2004). “Dissimilar welding of nickel-based Alloy 690 to SUS 304L with Ti addition.” J. Nucl. Mater., 335(1), 59-69.

Naffakh, H., Shamanian, M. and Ashrafizadeh, F. (2009). “Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657.” J. Mater. Process. Technol., 209(7), 3628-3639.

Hosseini, H.S., Shamanian, M.and Kermanpur, A. (2011). “Characterization of microstructures and mechanical properties of Inconel 617/310 stainless steel dissimilar welds.” Mater. Charact., 62(4), 425-431.

Patterson, R. and Milewski, J.O. (1985). “GTA Weld Cracking-Alloy 625 to 304.” Weld. J., 64(8), 227.

Sridhar, R., Ramkumar, K.D.and Arivazhagan, N. (2014). “Characterization of microstructure, strength, and toughness of dissimilar weldments of Inconel 625 and duplex stainless steel SAF 2205.” Acta Metall. Sin. (Engl. Lett.), 27(6), 1018-1030.

Wilson, I.L.W., Gourley, R.G., Walkosak, R.M.and Bruck, G.J. (1991). “The effect of heat input on microstructure and cracking in alloy 625 weld overlays.” Proceedings of the International Symposium on the Metallurgy and Applications of Superalloys, 718(625), 735-747.

Caiazzo, F., Alfieri, V., Cardaropoli, F.and Sergi, V. (2017). “Investigation on edge joints of Inconel 625 sheets processed with laser welding.” Opt. Laser Technol., 93, 180-186.

Ramkumar, K.D., Mithilesh, P., Varun, D., Reddy, A.R.G., Arivazhagan, N., Narayanan, S.and Kumar, K.G. (2014). “Characterization of microstructure and mechanical properties of Inconel 625 and AISI 304 dissimilar weldments.” ISIJ Int., 54(4), 900-908.

Kumar, K.G., Ramkumar, K.D. and Arivazhagan, N. (2015). “Characterization of metallurgical and mechanical properties on the multi-pass welding of Inconel 625 and AISI 316L.” J. Mech. Sci. Technol, 29(3), 1039-1047.

Ramkumar, K.D., Abraham, W.S., Viyash, V., Arivazhagan, N. and Rabel, A.M. (2017). “Investigations on the microstructure, tensile strength and high temperature corrosion behaviour of Inconel 625 and Inconel 718 dissimilar joints.” J. Manuf. Process., 25, 306-322.

Siores, E. and Do Rego, D. (1995). “Microwave applications in materials joining.” J. Mater. Process. Technol., 48(1-4), 619-625.

Barmatz, M., Jackson, H.W. and Radtke, R.P. (2000). U.S. Patent No. 6,054,693. Washington, DC: U.S. Patent and Trademark Office.

Budinger, D.E. (2008). U.S. Patent No. 7,775,416. Washington, DC: U.S. Patent and Trademark Office.

Srinath, M.S., Sharma, A.K.and Kumar, P. (2011). “A novel route for joining of austenitic stainless steel (SS-316) using microwave energy.” Proc. Inst. Mech. Eng., Part B, 225(7), 1083-1091.

Gamit, D., Mishra, R.R. and Sharma, A.K. (2017). “Joining of mild steel pipes using microwave hybrid heating at 2.45 GHz and joint characterization.” J. Manuf. Process, 27, 158-168.

Srinath, M.S., Sharma, A.K. and Kumar, P. (2011). “A new approach to joining of bulk copper using microwave energy.” Mater. Des., 32(5), 2685-2694.

Singh, S., Suri, N.M. and Belokar, R.M. (2015). “Characterization of joint developed by fusion of aluminum metal powder through microwave hybrid heating.” Mater. Today: Proc., 2(4-5), 1340-1346.

Singh, S., Singh, P., Gupta, D., Jain, V., Kumar, R. and Kaushal, S. (2018). Development and characterization of microwave processed cast iron joint. Eng. Sci. Technol. Int. J., doi: https://doi.org/10.1016/j.jestch.2018.10.012.

Bansal, A., Sharma, A.K., Kumar, P. and Das, S. (2015). “Structure-property correlations in microwave joining of Inconel 718.” JOM, 67(9), 2087-2098.

Badiger R I, Narendranath S and Srinath M S. (2018). Microstructure and mechanical properties of Inconel-625 welded joint developed through microwave hybrid heating.Proc. Inst. Mech. Eng., Part B, 232(14), 2462-2477.

Badiger R I, Narendranath S and Srinath M S. (2019). Optimization of process parameters by taguchi grey relationalanalysis in joining Inconel-625 through microwave hybrid heating.Metallogr., Microstruct., Anal., 8(1), 92-108.

Badiger R I, Narendranath S, Srinath MS, Ajit M Hebbale. (2019).Effect of power input on metallurgical and mechanical characteristics of Inconel-625 welded joints processed through microwave hybrid heating. Trans. Indian Inst. Met. 2019, 72(3), 811–824.

Sharma A, Sehgal S, Goyal D. (2020). Effects of process parameters in joining of Inconel-625 alloy through microwave hybrid heating. Mater. Today: Proc. https://doi.org/10.1016/j.matpr.2020.04.590.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Badiger, R.I., Hebbale, A.M., Manjaiah, M. et al. A Comparative Studyon Characteristics of Inconel-625 Joints Developed through Microwave Hybrid Heating and Tungsten Inert Gas Welding. Trans Indian Inst Met 74, 531–540 (2021). https://doi.org/10.1007/s12666-021-02188-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02188-8