Abstract

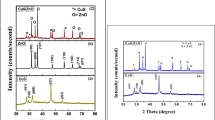

Nanostructured ZnO/CdS composites were synthesized using hydrothermal method by varying the sulphur source; thiourea (TU) and thioglycolic acid (TGA). Pure ZnO and two samples of CdS were prepared by varying the sulphur source in order to compare the results of the nanocomposite with the pure nanomaterials. X-ray diffraction analysis shows the average particle size of the ZnO/CdS (TU) and ZnO/CdS (TGA) nanocomposite to be 12.81 nm and 25 nm, respectively. High resolution TEM analysis shows the particle size of ZnO/CdS (TU) and ZnO/CdS (TGA) to be 12 and 17 nm respectively. UV- visible- reflectance spectra were recorded and the band gaps were estimated to be 2.4 eV and 2.84 eV for ZnO/CdS (TU) and ZnO IR/CdS (TGA). The porosity of ZnO/CdS (TU) was 14 nm and ZnO/CdS (TGA) was 2.5 nm. The photocatalytic activity for the degradation of Mordant black 11 dye under sunlight was studied.

Similar content being viewed by others

References

H. R. Pant, B. Pant, H. J. Kim, A. Amarjargal, C. H. Park, L. D. Tijing, E. K. Kim, and C. S. Kim (2013). Ceram. Int. 39, 5083–5091.

D. Lu, Y. Zhang, S. Lin, L. Wang, and C. Wang (2013). J. Alloys Compd. 579, 336–342.

M. Sumathi, A. Prakasam, and P. M. Anbarasan (2020). J. Clust. Sci. 31, 277–286.

L. Reijenders (2008). J. Hazard. Mater. 152, 440–445.

H. R. Pant, C. H. Park, B. Pant, L. D. Tijing, H. Y. Kim, and C. S. Kim (2012). Ceram. Int. 38, 2943–2950.

P. K. J. Robertson, J. M. C. Robertson, and D. W. Bahnemann (2012). J. Hazard. Mater. 211–212, 161–171.

D. Khayammi, A. A. Ensafi, N. Khazemifard, and B. Rezaei (2020). Environ. Sci. Pollut. Res. 27, 8759–8771.

K. M. Lee, S. B. Abdul Hamid, and C. W. Lai (2015). Mater. Sci. Semicond. Process. 39, 40–48.

P. Kundu, P. A. Deshpande, G. Madras, and N. Ravishankar (2011). J. Mater. Chem. 21, 4209–4216.

K. Dong, F. X. Qiu, X. R. Guo, J. C. Xu, D. Y. Yang, and K. C. He (2013). Polym. Plast. Technol. 52, 452–460.

V. Ramasamy, C. Anandan, and G. Murugadoss (2013). Mater. Sci. Semicond. Process. 16, 1759–1764.

G. Yang, W. Yan, Q. Zhang, S. Shen, and S. Ding (2013). Nanoscale 5, 12432–12439.

G. Thirumala Rao, B. Babu, R. Joyce Stella, V. Pushpa Manjari, C. Venkata Reddy, J. Shim, and R. V. S. S. N. Ravikumar (2015). J. Mol. Struct 1081, 254–259.

P. Lu, W. Zhou, Y. Li, J. Wang, and P. Wu (2017). Appl. Surf. Sci. 399, 396–402.

D. Anbuselvan and S. Muthukumaran (2015). Opt. Mater. 42, 124–131.

D. Suresh, P. C. Nethravathi, Udayabhanu, M. A. Pavan Kumar, H. Raja Naika, H. Nagabhushana, and S. C. Sharma (2015). Mater. Sci. Semicond. Process. 40, 759–765.

S. A. M. Lima, F. A. Sigoli, M. Jafelicci Jr., and M. R. Davolos (2001). Int. J. Inorg. Mater. 3, 749–754.

C. Unni, D. Philip, and K. G. Gopchandran (2008). Spectrochim. Acta A 71, 1402–1407.

D. Bera, L. Qian, S. Sabui, S. Santra, and P. H. Holloway (2008). Opt. Mater. 30, 1233–1239.

O. M. Ntwaeaborwa, R. E. Kroon, V. Kumar, T. Dubroca, J. P. Ahn, J. K. Park, and H. C. Swart (2009). J. Phys. Chem. Solids 70, 1438–1442.

T. Senasu, T. Chankhanittha, K. Hemavibool, and S. Nanan (2020). Mater Sci Semicond Process. https://doi.org/10.1016/j.mssp.2020.105558.

V. Eskizeybek, F. Sar, H. Gulce, A. Gulce, and A. Avc (2012). Appl. Catal. 119–120, 197–206.

G. Tao, Q. Li, and T. Wang (2005). Chem. Mater. 17, 887–892.

M. H. Habibi and M. H. Rahmati (2014). Spectrochim. Acta A 133, 13–18.

L. Irimpan, V. P. N. Nampoor, and P. Radhakrishnan (2008). J. Appl. Phys. 103, 094914.

T. K. Jana, A. Pal, and K. Chatterjee (2014). J. Alloys Compd. 583, 510–515.

S. Khanchandani, S. Kundu, A. Patra, and A. K. Ganguli (2012). J. Phys. Chem. C 116, 23653–23662.

R. M. Kong, Y. Zhao, Y. Zheng, and F. Qu (2017). RSC Adv. 7 (50), 31365–31371.

J. Liu, K. Zhu, B. Sheng, Z. Li, G. Tai, J. Qiu, and P. Liu (2015). J. Alloys Compd. 618, 67–72.

H. Zhao, Y. Dong, P. Jiang, G. Wang, H. Miao, R. Wu, and C. Zhang (2015). ACS Sustain. Chem. Eng. 3, 969–977.

Q. Shen, X. Zhao, S. Zhou, W. Hou, and J. J. Zhu (2011). J. Phys. Chem. C 115, 7958–17964.

J. K. Vaishnav, S. S. Arbuj, S. B. Rane, and D. P. Amalnerkar (2014). RSC Adv. 4, 47637–47642.

X. Wang, G. Liu, L. Wang, Z. G. Chen, G. Q. Lu, and H. M. Cheng (2012). Adv. Energy Mater. 2, 42–46.

Acknowledgements

Authors are grateful to UGC Minor Research Project [MRP-5666/15 (SERO/UGC)] for providing financial support to undertake this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharon Tamil Selvi, S., Hannah Priya, G., Ragu, R. et al. Exploring the Outcomes of Sulphur Sources on ZnO/CdS Nanocomposites Towards Photocatalytic Degradation of Mordant Black 11 Dye. J Clust Sci 33, 375–386 (2022). https://doi.org/10.1007/s10876-020-01963-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10876-020-01963-9