Abstract

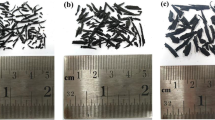

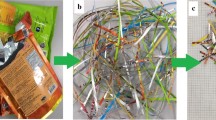

This study focuses on the development and assessment of greener and sustainable mix of self-compacting rubberised concrete (SCRC) utilising commonly available waste materials such as fly ash, worn tires, and polyethylene terephthalate (PET) drinking bottles as fibres. Ten mixes containing ground tire rubber and PET fibres were investigated under compression, split tension, and flexure. In 05 out of 10 mixes, SCRC contained 35% fly ash by mass substitution of cement and ground tire rubber to substitute 0, 5, 10, 15, and 20% masses of fine aggregates. The remaining 05 mixes of SCRC contained a fixed 2% volume fraction of PET fibres measured by the volume of concrete. The compression, split tension, and flexure tests were performed at 28 days to assess the effects of ground tire rubber and PET fibres on the strengths, compressive stress–strain behaviour, and load–deformation behaviour. The results indicated that the replacement of 15% mass of fine aggregates with ground tire rubber is optimum without impairing the strengths of concrete. The PET fibres played a role in stabilising and improving the post-peak response in the compression and the flexure. Overall, the use of ground tire rubber as fine aggregates and PET fibres as reinforcement in concrete improved the response of concrete in compression and flexure.

Similar content being viewed by others

References

AbdelAleem BH, Hassan AA (2018) Development of self-consolidating rubberised concrete incorporating silica fume. Constr Build Mater 161:389–397

AbdelAleem BH, Ismail MK, Hassan AA (2018) The combined effect of crumb rubber and synthetic fibers on impact resistance of self-consolidating concrete. Constr Build Mater 162:816–829

Al-Tayeb MM, Bakar BA, Ismail H, Akil HM (2013) Effect of partial replacement of sand by recycled fine crumb rubber on the performance of hybrid rubberised-normal concrete under impact load: experiment and simulation. J Cleaner Prod 59:284–289

Ali AS, Hasan TM (2020) Flexural behavior of fiber reinforced self-compacting rubberized concrete beams. J Eng 26:111–128

Aslani F, Gedeon R (2019) Experimental investigation into the properties of self-compacting rubberised concrete incorporating polypropylene and steel fibers. Struct Concrete 20:267–281

Aslani F, Ma G, Wan DLY, Le VXT (2018) Experimental investigation into rubber granules and their effects on the fresh and hardened properties of self-compacting concrete. J Clean Prod 172:1835–1847

ASTM (2010) Standard test method for flexural strength of concrete (using simple beam with third-point loading), vol 100.

ASTM (2011) Standard test method for splitting tensile strength of cylindrical concrete specimens.

ASTM (2012a) Standard specification for Portland cement. ASTM International, West Conshohocken

ASTM (2012b) Standard test method for compressive strength of cylindrical concrete specimens. ASTM, West Conshohocken

Ayub T, Khan SU, Ayub A (2019) Analytical model for the compressive stress–strain behavior of PVA-FRC. Constr Build Mater 214:581–593

Bencardino F, Rizzuti L, Spadea G, Swamy RN (2008) Stress-strain behavior of steel fiber-reinforced concrete in compression. J Mater Civ Eng 20:255

BIBM, EFNARC (2005) The European guidelines for self-compacting concrete

Bušić R, Miličević I, Šipoš TK, Strukar K (2018) Recycled rubber as an aggregate replacement in self-compacting concrete—literature overview. Materials 11:1729

Dinesh Y, Rao CH (2017) Strength characteristics of fibre reinforced concrete using recycled PET. Int J Civil Eng Technol (IJCIET) 8:092–099

Eldin NN, Senouci AB (1993) Rubber-tire particles as concrete aggregate. J Mater Civ Eng 5:478–496

Elghazouli A, Bompa D, Xu B, Ruiz-Teran A, Stafford P (2018) Performance of rubberised reinforced concrete members under cyclic loading. Eng Struct 166:526–545

Fraternali F, Ciancia V, Chechile R, Rizzano G, Feo L, Incarnato L (2011) Experimental study of the thermo-mechanical properties of recycled PET fiber-reinforced concrete. Comp Struct 93:2368–2374

Ganesan N, Raj JB, Shashikala A (2013) Flexural fatigue behavior of self compacting rubberised concrete. Constr Build Mater 44:7–14

Güneyisi E (2010) Fresh properties of self-compacting rubberised concrete incorporated with fly ash. Mater Struct 43:1037–1048

Güneyisi E, Gesoglu M, Naji N, İpek S (2016) Evaluation of the rheological behavior of fresh self-compacting rubberised concrete by using the Herschel-Bulkley and modified Bingham models. Arch Civil Mech Eng 16:9–19

Güneyisi E, Gesoğlu M, Özturan T (2004) Properties of rubberised concretes containing silica fume. Cem Concr Res 34:2309–2317

Hilal NN (2017) Hardened properties of self-compacting concrete with different crumb rubber size and content. Int J Sustain Built Environ 6:191–206

Irwan J, Asyraf R, Othman N, Koh KH, Annas MMK, Faisal S (2013) The mechanical properties of PET fiber reinforced concrete from recycled bottle wastes. Adv Mater Res,pp 347–351

Ismail MK, De Grazia MT, Hassan AA (2015) Mechanical properties of self-consolidating rubberised concrete with different supplementary cementing materials. In: Proceedings of the International Conference on Transportation and Civil Engineering (ICTCE’15), London, UK, pp 21–22

Ismail MK, Hassan AA (2016) Use of metakaolin on enhancing the mechanical properties of self-consolidating concrete containing high percentages of crumb rubber. J Clean Prod 125:282–295

Ismail MK, Hassan AA (2017) Impact resistance and mechanical properties of self-consolidating rubberised concrete reinforced with steel fibers. J Mater Civ Eng 29:04016193

Ismail MK, Hassan AA, Ridgley KE, Colbourne B (2018) Steel-fiber self-consolidating rubberized concrete subjected to impact loading. International Congress on Polymers in Concrete. Springer, Heidelberg, pp 397–403

Jedidi M, Gargouri A, Daoud A (2014) Effect of rubber aggregates on the thermophysical properties of self-consolidating concrete. Int J Thermal Environ Eng 8:1–7

Khalil E, Abd-Elmohsen M, Anwar AM (2015) Impact resistance of rubberised self-compacting concrete. Water Sci 29:45–53

Khan SU, Ayub T (2020) Flexure and shear behaviour of self-compacting reinforced concrete beams with polyethylene terephthalate fibres and strips. Structures 25:211. https://doi.org/10.1016/j.istruc.2020.02.023

Khan MM, Sharma A, Panchal S (2017) Use of crumb rubber as replacement over aggregate concrete. Int J Civil Eng Technol 8(82):148–152

Meddah A, Beddar M, Bali A (2014) Use of shredded rubber tire aggregates for roller compacted concrete pavement. J Clean Prod 72:187–192

Mishra M, Panda K (2015) An experimental study on fresh and hardened properties of self compacting rubberised concrete. Indian J Sci Technol 8:1–10

Moustafa A, ElGawady MA (2015) Mechanical properties of high strength concrete with scrap tire rubber. Constr Build Mater 93:249–256

Murthy NK, Rao AN, Reddy IR (2016) Comparison of cost analysis between self compacting concrete and normal vibrated concrete. Int J Civil Eng Technol 5:34–41

Murugan RB, Sai ER, Natarajan C, Chen S-E (2017) Flexural fatigue performance and mechanical properties of rubberised concrete. Građevinar 69:983–990

Nuruddin MF, Ullah Khan S, Shafiq N, Ayub T (2015) Strength prediction models for PVA fiber-reinforced high-strength concrete. J Mater Civ Eng 27:04015034

Reddy CS, Sai KR, Kumar PR, Kumar GR (2013) Recycled aggregate based self compacting concrete (RASCC) for structural applications. In: Paper presented at the RN Raikar Memorial international conference & Dr. Suru Shah symposium on advances in science & technology of concrete, Mumbai, 20–12–2013

Si R, Wang J, Guo S, Dai Q, Han S (2018) Evaluation of laboratory performance of self-consolidating concrete with recycled tire rubber. J Clean Prod 180:823–831

Sofi A (2018) Effect of waste tyre rubber on mechanical and durability properties of concrete–a review. Shams Eng J 9:2691–2700

Thomas M (2007) Optimising the use of fly ash in concrete, vol 5420. Portland Cement Association Skokie, IL

Yilmaz A, Degirmenci N (2009) Possibility of using waste tire rubber and fly ash with Portland cement as construction materials. Waste Manag 29:1541–1546

Yung WH, Yung LC, Hua LH (2013) A study of the durability properties of waste tire rubber applied to self-compacting concrete. Constr Build Mater 41:665–672

Zaoiai S, Makani A, Tafraoui A, Benmerioul F (2016) Optimisation and mechanical characterisation of self-compacting concrete incorporating rubber aggregates. Asian J CIvil Eng (BHRC) 17:817–829

Funding

This study is conducted in support of NED University of Engineering and Technology and its staff. There was no funding available for this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors had not received any research grants whatsoever for this study. The authors declare that there is no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Ayub, T., Khan, S.U. & Mahmood, W. Mechanical Properties of Self-Compacting Rubberised Concrete (SCRC) Containing Polyethylene Terephthalate (PET) Fibres. Iran J Sci Technol Trans Civ Eng 46, 1073–1085 (2022). https://doi.org/10.1007/s40996-020-00568-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-020-00568-6