Abstract

Sedimentation in dam reservoirs causes problems such as reducing storage volume and useful life of reservoirs, reducing the volume of flood control, sluices, tunnels, and turbines clogged, and other related issues. Despite the development of several methods to solve this problem, the sedimentation rate of the world’s dam reservoirs indicates the existence of this problem. The Hydrosuction Sediment Removal System discharges sediments inside the dam reservoir using the energy caused by the difference in water level in the reservoir and the output point of the system. This study is aimed to investigate the effect of geometric properties of the hydrosuction system (effective head, suction pipe diameter, and suction pipe inlet angle) on its performance and to understand the flow characteristics and behaviors in the hydrosuction dredging operation. Quantitative comparison of the results revealed that, with the increase in the suction pipe diameter from 478 to 956, the growth of the effective head from 21 × 103 to 34 × 103, and the increase in the suction pipe inlet angle from 30º to 90º, the maximum diameter and depth of the scour hole increased by 103% and 275%, 22% and 49%, and 38% and 50%, respectively. At the beginning of the desilting process by the hydrosuction system, seepage flow through deposits removed sediment particles and, along with the scour hole dimensions development, it reduced the effect of this flow type. Irregular vortexes were observed in the final stages of the desilting process. These vortexes caused limited development in the scour hole.

Similar content being viewed by others

Abbreviations

- H :

-

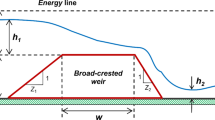

Effective head caused by the difference between the water level inside the reservoir and the system output point (L);

- D P :

-

Suction pipe diameter (L);

- α :

-

Suction pipe inlet angle relative to the horizon;

- D 50 :

-

Median size of the sediment particles (L);

- ρ w :

-

Water density (ML−3);

- ρ s :

-

Particle density (ML−3);

- Gs :

-

Specific gravity of sediment;

- μ :

-

Dynamic viscosity of water (ML−1 T−1),

- Re:

-

Reynolds number in suction pipe inlet;

- L :

-

Suction pipe length (L);

- σg :

-

Geometric standard deviation of sediment;

- g :

-

Acceleration due to gravity (LT−2);

- E :

-

Hydrosuction system efficiency;

- V s :

-

Volume of removed sediment (L3);

- V w :

-

Volume of harvested water (L3);

- D Scour hole :

-

Maximum diameter of scour hole (L);

- Z Scour hole :

-

Maximum depth of scour hole (L)

References

Asiaban P, Kouchakzadeh S, Asiaban S (2017) Enhanced hydrosuction performance for cohesive sediment removal in low-head reservoirs. Ain Shams Eng J 4:491–497

Brahme SB, Herbich JB (1986) Hydraulic model studies for suction cutterheads. J Waterw Port Coast Ocean Eng 112(5):591–606

Chen SC, Wang SC, Wu CH (2010) Sediment removal efficiency of siphon dredging with wedge-type suction head and float tank. Int J Sedim Res 25(2):149–160

Crookston BM (2010) Labyrinth Weirs. Doctoral Thesis, University of Utah State

Forutan-Eghlidi M, Zounemat-Kermani M, Rahimpour M, Moghbeli A (2019) Experimental study on the effect of distance of suction tube mouth from sediment surface on the hydrosuction system performance. J Hydraulic 13(3):47–58 (in Persian)

Garcia MH (2007) Sedimentation engineering. ASCE, Restone

Heller V (2011) Scale effects in physical hydraulic engineering models. J Hydaulic Res 49(3):293–306

Hotchkiss H, Huang X (1995) Hydrosuction Sediment-Removal Systems (HSRS): principles and field test. J Hydraul Eng 121(6):479–489

Kantoush SA, Sumi T, Murasaki M (2011) Evaluation of sediment bypass efficiency by flow field and sediment concentration monitoring techniques. J Hydra Eng JSCE 67(4):I_169–I_174

Ke WT, Chen YW, Hsu HC, Toigo K, Weng WC, Capart H (2016) Influence of sediment consolidation on hydrosuction performance. J Hydraul Eng 142(10):04016037

Jacobsen T (1997) Sediment problem in reservoirs control of sediment deposits. Doctoral Thesis. Norwegian university of science and technology (NTNU)

Jacobsen T (2006) Sediment removal at the Malana reservoir. India Int J Hydropower Dams 13(1):74–44

Knauss J (1987) Swirling flow problems at intakes. 1AA, Balkema, Rotterdam

Mahdavi-meymand A, Zounemat-Kermani M, Qaderi K (2020) Experiment study of hydrosuction dredging blockage depth under different hydralic conditions. Environ Water Eng 6(3):234–244 (in persian)

Miyakawa M, Hakoishi N, Sakurai T (2014) Development of the sediment removal suction pipe by laboratory and filed experiment. CIGB-ICOLD 82th International Symposium on Dams in A Global Environmental Challenges, Bali, Indonesia

Morris GL, Fan J (1997) Reservoir sedimentation handbook. McGraw-Hill, New York

Lee C, Foster G (2013) Assessing the potential of reservoir outflow management to reduce sedimentation using continuous turbidity monitoring and reservoir modeling. J Hydrol Processes 27(10):1426–1439

Liu J, Minami S, Otsuki H, Liu B, Ashida K (2005) Environmental impacts of coordinated sediment flushing. J Hydaulic Res 42(5):461–472

Pishgar R, Ayyoubzade SA, Ghodsian M, Saneie M (2018) The influence of burrowing-type suction pipe geometrical and mechanical specifications on the hydrosuction method performance. ISH J Hydraul Eng. https://doi.org/10.1080/09715010.2018.1531732

Qian N (1982) Reservoir sedimentation and slope stability; technical and environmental effects. In: Fourteenth International Congress on Large Dams, Transactions, Rio de Janeiro, Brazil Vol. 3, pp. 639–690

Rehbinder G (1984) Sediment removal with a siphon at critical flux. J Hydraul Res 32(6):845–860

Sakurai T, Hakoishi N (2012) Hydraulic characteristics of the Burrowing Type Sediment Removal Suction Pipe. In: Proceedings of the International Symposium on Dams for a Chaning World - 80th Annual Meeting and 24th Congress of ICOLD. Kyoto, Japan

Shrestha HS (2012) Application of hydrosuction sediment removal system (HSRS) on peaking ponds. J Water Energy Environ 11:43–48

Tao Y, Li C, Min X, Min Z (2012) Siphon pipeline resistance characteristic research. J Procedia Eng 28:99–104

Ullah SM, Mazurek KA, Rajaratnam N, Reitsma SR (2005) Siphon removal of cohesionless materials. J Waterw Port Coastal Ocean Eng 3(115):115–122

Wang H, Kondolf M (2014) Upstream sediment control dams: five decades of experience in the rapidly eroding Dahan river basin. Taiwan J Am Water Resour Assoc 50(3):735–747

Winterwerp JC, van Kesteren, van Prooijen WGM, Jacobs W (2012) A conceptual framework for shear flow-induced erosion of soft cohesive sediment beds. J Geophys Res 117(C10):C10020

Zreik DA, Krishnappan BG, Germaine JT, Madsen OS, Ladd CC (1998) Erosional and mechanical strengths of deposited cohesive sediments. J Hydraul Eng 124(11):1076–1085

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Michael Nones, Ph.D. (CO-EDITOR-IN-CHIEF).

Rights and permissions

About this article

Cite this article

Moghbeli, A., Khanjani, M.J. & Zounemat-Kermani, M. An experimental study of the geometric performance of the hydrosuction dredging system. Acta Geophys. 69, 271–283 (2021). https://doi.org/10.1007/s11600-020-00524-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11600-020-00524-y