Abstract

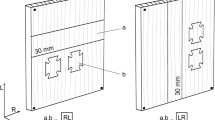

This paper introduces a new test configuration for the determination of panel shear properties in structural sizes. This original test configuration has been successfully applied to calculate the shear properties of beech plywood. A numerical model has been developed to evaluate the influence of such a novel setup in comparison to the common standard. The research includes the mechanical characterization of a total of 36 samples using Digital Image Correlation (DIC) to measure the in plane displacements. The use of DIC has been proven to be efficient to measure the shear properties and also acts as a tool to ensure that the solicitation was adequate during the test. Finally, the results highlight the interest to actually perform the proposed test instead of using the alternative density-based equivalencies provided by the standards.

Similar content being viewed by others

References

Dobbin McNatt J (1969) Rail shear test for evaluating edgewise shear properties of wood base panel products. tech. rep., U.S.D.A Forest Service, Forest Products Laboratory. Madison

Munthe B, Ethington RL (1968) Method for evaluating shear properties of wood. US Department of Agriculture, Forest Service, Forest Products Laboratory

Rune Z (1994) Evaluation Of test methods for wood based panels. Determination of shear modulus and shear strangth. Tech. Rep. Nordtest Project No. 1060–92, Swedish National Testing and Research Institute

Ehlbeck J, Colling F (1984) Determination of panel shear strength and shear modulus of beech plywood in structural sizes. (SWITZERLAND)

Wilson CR, Parasin AV (1979) A comparison of plywood modulus of rigidity determined by the ASTM and RILEM/CIB-3tt test methods, (Austria)

Booth LG, Kuipers J, Noren B, Wilson CR (1977) Methods of test for the determination of mechanical properties of plywood, (Sweden)

CEN (2005) EN 789 timber structures - test methods - determination of mechanical properties of wood based panels

CEN (2011) EN 12369-2 wood-based panels - characteristic values for structural design - Part 2: Plywood

Yoshihara H, Yoshinobu M (2015) Young’s modulus and shear modulus of solid wood measured by the flexural vibration test of specimens with large height/length ratios. Holzforschung 69(4):493–499

Cavalli A, Marcon B, Cibecchini D, Mazzanti P, Fioravanti M, Procino L, Togni M (2017) Dynamic excitation and FE analysis to assess the shear modulus of structural timber. Mater Struct 50(2):130

Vacher P, Dumoulin S, Morestin F, Mguil-Touchal S (1999) Bidimensional strain measurement using digital images. Proc Inst Mech Eng C J Mech Eng Sci 213(8):811–817

Wattrisse B, Chrysochoos A, Muracciole J-M, Némoz-Gaillard M (2001) Analysis of strain localization during tensile tests by digital image correlation. Exp Mech 41(1):29–39

Sutton M, Wolters W, Peters W, Ranson W, McNeill S (1983) Determination of displacements using an improved digital correlation method. Image Vis Comput 1(3):133–139

Bruck H, McNeill S, Sutton MA, Peters W (1989) Digital image correlation using newton-Raphson method of partial differential correction. Exp Mech 29(3):261–267

Bornert M, Brémand F, Doumalin P, Dupré J-C, Fazzini M, Grédiac M, Hild F, Mistou S, Molimard J, Orteu J-J, Robert L, Surrel Y, Vacher P, Wattrisse B (2009) Assessment of digital image correlation measurement errors: methodology and results. Exp Mech 49(3):353–370

Jeong GY, Zink-Sharp A, Hindman DP (2009) Tensile properties of earlywood and latewood from loblolly pine (Pinus taeda) using digital image correlation. Wood Fiber Sci 41(1):51–63

Zink AG, Davidson RW, Hanna RB (2007) Strain measurement in wood using a digital image correlation technique. Wood Fiber Sci 27(4):346–359

Haldar S, Gheewala N, Grande-Allen K, Sutton M, Bruck H (2011) Multi-scale mechanical characterization of palmetto wood using digital image correlation to develop a template for biologically-inspired polymer composites. Exp Mech 51(4):575–589

CEA (2019) Cast3m

Guitard D (1987) Mécanique du matériau bois et composites. NABLA, cepadues ed.

Bergman R, Cai Z, Carll CG, Clausen CA, Dietenberger MA, Falk RH, Frihart CR, Glass SV, Hunt CG, Ibach RE (2010) Wood handbook: Wood as an engineering material. Forest Products Laboratory

Gérard J, Guibal D, Paradis S, Vernay M, Beauchêne J, Brancheriau L, Châlon I, Daigremont C, Détienne P, Fouquet D, Langbour P, Lotte S, Thévenon M-F, Méjean C, Thibaut A (2011) Tropix 7

Pöhler E, Klingner R, Künniger T (2006) Beech (Fagus sylvatica L.) – Technological properties, adhesion behaviour and colour stability with and without coatings of the red heartwood. Annals Forest Sci 63(2):129–137

Viguier J, Bourgeay C, Rohumaa A, Pot G, Denaud L (2018) An innovative method based on grain angle measurement to sort veneer and predict mechanical properties of beech laminated veneer lumber. Constr Build Mater 181:146–155

Viguier J, Marcon B, Girardon S, Denaud L (2017) Effect of forestry management and veneer defects identified by x-ray analysis on mechanical properties of laminated veneer lumber beams made of beech. BioResources

Acknowledgements

The present study was financed by the company Fernand BRUGERE. This study was performed thanks to the partnership build by BOPLI: a shared public-private laboratory build between Bourgogne Franche-Compté region, LaBoMaP and the company Fernand BRUGERE. The authors would also like to thank the Xylomat Technical Platform from the Xylomat Scientific Network funded by ANR-10-EQPX-16 XYLOFOREST.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Viguier, J., Marcon, B., Butaud, J.C. et al. Panel Shear of Plywood in Structural Sizes - Assessment Improvement Using Digital Image Correlation. Exp Tech 45, 195–206 (2021). https://doi.org/10.1007/s40799-020-00430-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-020-00430-4