Abstract

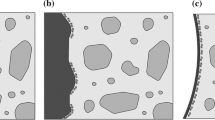

Steel–concrete–steel (SCS) structural systems have economic and structural advantages over traditional reinforced concrete; thus, they have been widely used. The performance of concrete made from recycled rubber aggregate from scrap tires has been evaluated since the early 1990s. The use of rubberized concrete in structural construction remains necessary because of its high impact resistance, increases ductility, and produces a lightweight concrete; therefore, it adds such important properties to SCS members. In this research, the use of different concrete core materials in SCS was examined. Twelve SCS specimens were subjected to push-out monotonic loading for inspecting their mechanical performance. One specimen was constructed from conventional normal weight concrete core, while the other specimens were constructed with modified core materials by either partial replacement of the coarse aggregate with crumb rubber (CR), the addition of oil palm fibre (OPF) to the concrete as a volume fraction of concrete, or both in the concrete cores. The investigated push-out specimens have a height of 450 mm and constructed from two hollow steel tubes with a square cross section of 100 mm and 5 mm in thickness which fixed to concrete prism using bolt end shear connectors. The detection of the mode of failure, load–slip as well as ductility behaviour, and the energy absorption capacity was investigated. The results revealed an improvement in the energy absorption (EA) capacity averagely by 55% for the specimen with 15% CR and 1.1% addition of OPF as a volume fraction of concrete in comparison with the reference specimens due to the high shear resistance.

Similar content being viewed by others

References

Leekitwattana M, Boyd SW, Shenoi RA. An alternative design of steel-concrete-steel sandwich beam. In: Proceedings of the 9th international conference on sandwich structures (ICSS-9), Pasadena, 14–16 June 2010.

Chu M, Song X, Ge H. Structural performance of steel-concrete-steel sandwich composite beams with channel steel connectors. In: Proceedings of the 22nd international conference on structural mechanics in reactor technology (SMiRT 22), San Francisco, 18–23 August 2013.

Ţibea C, Bompa DV. Ultimate shear response of ultra-high-performance steel fibre-reinforced concrete elements. Arch Civ Mech Eng. 2020;20:1–16.

Huang Z, Liew JYR. Steel-concrete-steel sandwich composite structures subjected to extreme loads. Int J Steel Struct. 2016;16(4):1009–28. https://doi.org/10.1007/s13296-016-0026-7.

Liew JYR, Sohel KMA. Structural performance of steel-concrete-steel sandwich composite structures. Adv Struct Eng. 2010;13(3):453–70. https://doi.org/10.1260/1369-4332.13.3.453.

Huang Z-Y, Wang J-Y, Richard Liew JY, William Marshall P. Lightweight steel–concrete–steel sandwich composite shell subject to punching shear. Ocean Eng. 2015;102:146–61. https://doi.org/10.1016/j.oceaneng.2015.04.054.

Varma AH, Malushte SR, Lai Z. Modularity and innovation using steel-plate composite (sc) walls for nuclear and commercial construction. In: Proceedings of the 11th international conference on advances in steel and concrete composite structures, Beijing, 3–5 December 2015.

El-sayed K, Khalil N, Backlesh T. Flexural behaviour of steel–concrete–steel sandwich slabs. Adv Res. 2016;8(1):1–13. https://doi.org/10.9734/air/2016/29007.

Liew JYR, Sohel KMA. Lightweight steel–concrete–steel sandwich system with J-hook connectors. Eng Struct. 2009;31(5):1166–78. https://doi.org/10.1016/j.engstruct.2009.01.013.

Sohel KMA, Richard Liew JY, Yan JB, Zhang MH, Chia KS. Behaviour of steel–concrete–steel sandwich structures with lightweight cement composite and novel shear connectors. Compos Struct. 2012;94(12):3500–9. https://doi.org/10.1016/j.compstruct.2012.05.023.

Abdul-Razaq A. Experimental and analytical study of the steel-concrete-steel beam under flexural behaviour. In: Proceedings of the 5th Jordanian international civil engineering conference, Amman, pp. 13–15 (2011).

Al-Gasham TSS. Experimental behaviour of steel-concrete-steel sandwich beams with truss configuration of shear connectors. J Eng. 2016;22(4):18–29.

Liew JYR, Sohel KMA, Koh CG. Impact tests on steel–concrete–steel sandwich beams with lightweight concrete core. Eng Struct. 2009;31(9):2045–59. https://doi.org/10.1016/j.engstruct.2009.03.007.

Xu B, Bompa DV, Elghazouli AY. Cyclic stress–strain rate-dependent response of rubberised concrete. Constr Build Mater. 2020;254:119253. https://doi.org/10.1016/j.conbuildmat.2020.119253.

Bompa DV, Elghazouli AY, Xu B, Stafford PJ, Ruiz-Teran AM. Experimental assessment and constitutive modelling of rubberised concrete materials. Constr Build Mater. 2017;137:246–60. https://doi.org/10.1016/j.conbuildmat.2017.01.086.

Miller SA, Cunningham PR, Harvey JT. Rice-based ash in concrete: A review of past work and potential environmental sustainability. Resour Conserv Recycl. 2019;146:416–30.

Abutaha F, Razak HA, Kanadasan J. Effect of palm oil clinker (POC) aggregates on fresh and hardened properties of concrete. Constr Build Mater. 2016;112:416–23.

Aslam M, Shafigh P, Jumaat MZ. Drying shrinkage of structural lightweight aggregate concrete containing blended oil palm bio-products. J Clean Prod. 2016;127:183–94.

Ibrahim HA, Razak HA. Effect of palm oil clinker incorporation on properties of pervious concrete. Constr Build Mater. 2016;115:70–7.

Mohammed BS, Al-Ganad MA, Abdullahi M. Analytical and experimental studies on composite slabs utilising palm oil clinker concrete. Constr Build Mater. 2011;25:3550–60.

Momoh EO, Osofero AI. Behaviour of oil palm broom (OPBF) reinforced concrete. Constr Build Mater. 2019;221:745–61.

Li N, Long G, Ma C, Fu Q, Zeng X, Ma K, Xie Y, Luo B. Properties of self-compacting concrete (SCC) with recycled tire rubber aggregate: a comprehensive study. J Clean Prod. 2019;236:117707.

Shariati M, Heyrati A, Zandi Y, Laka H, Toghroli A, Kianmehr P, Safa M, Salih MN, Poi-Ngian S. Application of waste tire rubber aggregate in porous concrete. Smart Struct Syst. 2019;24(4):553–66.

Li G, Garrick G, Eggers J, Abadie C, Stubblefield MA, Pang S-S. Waste tire fibre modified concrete. Compos B Eng. 2004;35(4):305–12. https://doi.org/10.1016/j.compositesb.2004.01.002.

U.S. Tire Manufacturers Association | The national trade association for tire manufacturers that make tires in the U.S. (n.d.).

ETRMA’s statistics on scrap tire collection and recycling in Europe. https://www.gdtc6.com/statistics-old-tyres-in-australia/ (Accessed 8 Apr 2019) (n.d.).

https://weibold.com/etrmas-statistics-on-scrap-tire-collection-and-recycling-in-europe/ (Accessed 8 Apr 2019).

ASTM C150/C150M-19a, Standard Specification for Portland Cement, ASTM International, West Conshohocken; 2019. http://www.astm.org

Antony J. Design of experiments for engineers and scientists. Oxford: Elsevier Science and Technology Books; 2003.

Braimah MN, Anozie AN, Odejobi OJ. Utilization of response surface methodology (RSM) in the optimization of crude oil refinery process, new Port-Harcourt Refinery, Nigeria. J Eng Sci Technol. 2016;3:4361–9.

Eurocode 4. Design of composite steel and concrete structures. (n.d.). https://doi.org/10.3403/03221508u.

Kwon G, Engelhardt MD, Klingner RE. Parametric studies and preliminary design recommendations on the use of postinstalled shear connectors for strengthening noncomposite steel bridges. J Bridge Eng. 2012;17(2):310–7. https://doi.org/10.1061/(asce)be.1943-5592.0000261.

Nielsen MP, Hoang LC. Limit analysis and concrete plasticity. Boca Raton: CRC Press; 2016. https://doi.org/10.1201/b10432.

Godat A, Qu Z, Lu XZ, Labossière P, Ye LP, Neale KW. Size effects for reinforced concrete beams strengthened in shear with CFRP strips. J Compos Constr. 2010;14(3):260–71. https://doi.org/10.1061/(asce)cc.1943-5614.0000072.

Buttry KE. Behaviour of stud shear connectors in lightweight and normal-weight concrete (Doctoral dissertation, University of Missouri-Columbia) (1965).

Ollgaard JG, Slutter RG, Fisher JW. Shear strength of stud connectors in lightweight and normal weight concrete. AISC Eng J. 71–10 (1971).

An L, Cederwall K. Push-out tests on studs in high strength and normal strength concrete. J Constr Steel Res. 1996;36(1):15–29. https://doi.org/10.1016/0143-974x(94)00036-h.

Aribert JM. Dimensionnement de poutres mixtes en connection partielle. In: Mixed structures including new materials, IABSE symposium, Brussels, pp. 215–220 (1990).

Johnson RP, Molenstra N. Partial shear connection in composite beams for buildings. Proc Inst Civ Eng. 1991;91(4):679–704. https://doi.org/10.1680/iicep.1991.17485.

Lorenc W, Kubica E. Behaviour of composite beams prestressed with external tendons: experimental study. J Constr Steel Res. 2006;62(12):1353–66. https://doi.org/10.1016/j.jcsr.2006.01.007.

Xue W, Ding M, Wang H, Luo Z. Static behaviour and theoretical model of stud shear connectors. J Bridge Eng. 2008;13(6):623–34. https://doi.org/10.1061/(asce)1084-0702(2008)13:6(623).

Pimentel-Gomes F. Course of experimental statistics. Piracaicaba: FEALQ; 2000. p. 15.

Gandomi AH, Alavi AH, Mousavi M, Tabatabaei SM. A hybrid computational approach to derive new ground-motion prediction equations. Eng Appl Artif Intell. 2011;24(4):717–32.

Acknowledgements

The authors gratefully acknowledge the support from the entire technical staff of the structural laboratory, civil engineering department, University of Technology. Moreover, the first two authors thanks the support from the University of Baghdad.

Funding

The authors received no specific funding for this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that have no conflict of interest.

Ethical approval

This article does not contain any studies with animals performed by any of the authors. This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Abdulhameed, A.A., Hanoon, A.N., Abdulhameed, H.A. et al. Push-out test of steel–concrete–steel composite sections with various core materials: behavioural study. Archiv.Civ.Mech.Eng 21, 17 (2021). https://doi.org/10.1007/s43452-021-00173-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00173-y