Abstract

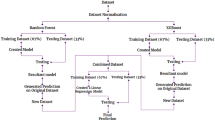

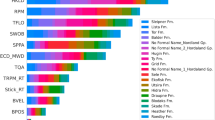

This paper established a model based on an ensemble method to predict strip crown using 230,000 coils of data obtained from a hot rolling line. Before modeling, a specific method was proposed to reduce noise and remove outliers, and a new dataset of 5657 samples was generated. Parameter tuning considering mean squared error (MSE) was carried out to establish three machine learning models including support vector machine (SVC), regression tree (RT), and random forest (RF). Determination coefficient (R2), mean absolute error (MAE) and root mean squared error (RMSE) were used as indicators to evaluate the prediction of models. Results showed that the RF had the best performance with the highest R2 of 0.707, as well as the lowest RMSE of 5.66 μm. Moreover, an additional method that repeated the three models 100 times was developed, and box plots were used to visualize the distribution of R2, MAE and RMSE. RF can correct for decision trees to reduce overfitting to their training set, improving the generalization, and in this paper, the trained RF which had stable performance is considered as the most recommended model. After that, for RF, rankings of rolling process variable were validated to make a comparison with the existing physical understanding.

Similar content being viewed by others

Abbreviations

- A:

-

Averaged data

- b:

-

Independent term

- C40 :

-

Strip crown

- CR :

-

Exit strip crown of model

- e :

-

A vector of all ones

- F B :

-

Bending force

- F R :

-

Rolling force

- h:

-

Thickness at 40 mm on the left

- h′:

-

Thickness at 40 mm on the right

- Hen :

-

Entry thickness

- Hex :

-

Exit thickness

- hc :

-

Thickness at the center of strip

- L:

-

Number of samples

- l 2 :

-

Barrel length

- MAE:

-

Mean absolute error

- MSE:

-

Mean squared error

- Q:

-

A positive semidefinite matrix

- \(R_{{{\text{BUR}}}}\) :

-

Back up roll crown

- \(R_{{{\text{WR}}}}\) :

-

Work roll crown

- R2 :

-

Determination coefficient

- RC:

-

Rolling cycle subset

- RF:

-

Random forest

- RMSE:

-

Root mean squared error

- RT:

-

Regression tree

- S R :

-

Rolling shifting

- S G :

-

Steel grade

- SG:

-

Steel grade subset

- ST:

-

Steel thickness subset

- SVM:

-

Support vector machine

- SVR:

-

Support vector regression

- SW:

-

Steel width subset

- W :

-

Exit width

- x:

-

Vector of input samples

- x′:

-

Vector of standard score

- y:

-

Predicted value

- \(\hat{y}\) :

-

Measured value

- \(\overline{y}\) :

-

The arithmetic means of y

- \(\alpha\) :

-

Dual coefficient

- \(\alpha^{ * }\) :

-

Dual coefficient

- \(\alpha_{{F_{{\text{R}}} }}\) :

-

Influence coefficients of rolling force for work up roll axial deflection

- \(\alpha_{{{\text{WR}}}}\) :

-

Influence coefficients of work roll crown for work up roll axial deflection

- \(\alpha_{{{\text{BUR}}}}\) :

-

Influence coefficients of back-up roll crown for work up roll axial deflection

- \(\alpha_{{{\text{WRS}}}}\) :

-

Influence coefficients of work roll shifting for work up roll axial deflection

- σ :

-

Standard deviation of x

- \(\phi\) :

-

Identity function

- \(\varepsilon\) :

-

Range of true predictions

- \(\eta\) :

-

Strip crown inherent constant

- \(\omega\) :

-

A vector to the hyperplane

- μ:

-

Mean of x

- \(\zeta\) :

-

Slack variable

- \(\zeta^{ * }\) :

-

Slack variable

References

Mücke, G., Pütz, P. D., & Gorgels, F. (2009). Methods of describing, assessing, and influencing shape deviations in strips (flat-rolled steel processes advanced technologies). Boca Raton: CRC.

Stone, M. D., & Gray, R. (1965). Theory and practical aspects in crown control. Iron and Steel Engineer, 42, 73–77.

Shohet, K. N., & Townsend, N. A. (1968). Roll bending methods of crown control in four-high plate mills. Journal of Iron and Steel Research International, 1088–1098.

Ono, H., Watanabe, T., Yoshimoto, K., & Kaga, S. (1996). Industrial application of the HCX-MILL to hot strip mills. Hitachi Review, 45, 271–278.

Yasuda, K., Narita, K., Kobayashi, K., & Maeno, I. (1991). Shape controllability in new 6-high mill (UC-4 mill) with small diameter work rolls. ISIJ International, 31(6), 594–598.

Aratani, H., Ozono, R., & Nakano, T. (1993). Expansion of pair cross mill applications to hot and cool rolling mills. Iron and Steel Engineer, 70, 32–37.

Bald, W., Beisemann, G., Feldmann, H., & Schultes, T. (1987). Continuously variable crown (CVC) rolling. Iron and Steel Engineer, 64, 32–41.

Zhang, T., Li, L., Shi-hong, L., Zhang, J.-B., & Gong, H. (2018). Comparisons of flow behavior characteristics and microstructure between asymmetrical shear rolling and symmetrical rolling by macro/micro coupling simulation. Journal of Computational Science, 29, 142–152.

Faini, F., Attanasio, A., & Ceretti, E. (2018). Experimental and FE analysis of void closure in hot rolling of stainless steel. Journal of Materials Processing Technology, 259, 235–242.

Mohanty, I., Bhattacharjee, D., & Datta, S. (2011). Designing cold rolled IF steel sheets with optimized tensile properties using ANN and GA. Computational Materials Science, 50(8), 2331–2337.

Bu, H. N., Zhou, H. G., Yan, Z. W., & Zhang, D. H. (2019). Multi-objective optimization of bending force preset in cold rolling. Engineering Computations, 36(6), 2048–2065.

Kim, J. M., Won, S. B., & Kim, B. M. (2018). Study on hot rolling process of the D51 large-diameter threaded bars (vol 32, pg 1761, 2018). Journal of Mechanical Science and Technology, 32(6), 2969–2970.

Bouhouche, S., Yazid, L. L., Hocine, S., & Bast, J. (2010). Evaluation using online support-vector-machines and fuzzy reasoning. Application to condition monitoring of speeds rolling process. Control Engineering Practice, 18(9), 1060–1068.

Hu, Y., Sun, J., Peng, W., & Zhang, D. (2020). A novel forecast model based on CF-PSO-SVM approach for predicting the roll gap in acceleration and deceleration process. Engineering Computations.

Agarwal, K., Shivpuri, R., Zhu, Y. J., Chang, T. S., & Huang, H. (2011). Process knowledge based multi-class support vector classification (PK-MSVM) approach for surface defects in hot rolling. Expert Systems with Applications, 38(6), 7251–7262.

Jung, J., Yoon, J. I., Park, S. J., Kang, J. Y., Kim, G. L., & Song, Y. H. (2019). Modelling feasibility constraints for materials design: Application to inverse crystallographic texture problem. Computational Materials Science, 156, 361–367.

Xu, K., Ai, Y. H., & Wu, X. Y. (2013). Application of multi-scale feature extraction to surface defect classification of hot-rolled steels. International Journal of Minerals Metallurgy and Materials, 20(1).

Okura, T., Ahmad, I., Kano, M., Hasebe, S., Kitada, H., & Murata, N. (2013). High-performance prediction of molten steel temperature in Tundish through gray-box model. ISIJ International, 53(1), 76–80.

Li, L., Wang, Y. Y., Xu, J. T., Flora, J. R. V., Hoque, S., & Berge, N. D. (2018). Quantifying the sensitivity of feedstock properties and process conditions on hydrochar yield, carbon content, and energy content. Bioresource Technology, 262, 284–293.

Wang, B., Qu, X. L., & Chen, Y. (2019). Identification of the potential prognostic genes of human melanoma. Journal of Cellular Physiology, 234(6), 9810–9815.

Wang, Z. Y., Wang, Y. R., Zeng, R. C., Srinivasan, R. S., & Ahrentzen, S. (2018). Random forest based hourly building energy prediction. Energy Buildings, 171, 11–25.

Peng, K. X., Zhong, H., Zhao, L., Xue, K., & Ji, Y. D. (2014). Strip shape modeling and its setup strategy in hot strip mill process. International Journal of Advanced Manufacturing Technology, 72(5–8), 589–605.

Deng, J., Sun, J., Peng, W., Hu, Y., & Zhang, D. (2019). Application of neural networks for predicting hot-rolled strip crown. Applied Soft Computing, 78, 119–131.

Wang, G. D. (1990). Fundamental of strip crown and flatness (1st ed.). China: China Railway Publishing House.

Cortes, C., & Vapnik, V. (1995). Support-vector networks. Machine Learning, 20(3), 273–297.

Hastie, T., Tibshirani, R., & Friedman, J. (2009). The elements of statistical learning (2nd ed.). New York: Springer.

Breiman, L. (2001). Random forests. Machine Learning, 45(1), 5–32.

Acknowledgements

This study is financially supported by the National Key Research and Development Program of China (No. 2018YFB1308700), the National Natural Science Foundation of China (Nos. 51704067, 51774084, and 51634002), the Fundamental Research Funds for the Central Universities (Nos. N160704004, N170708020, and N2004010), and Liaoning Revitalization Talents Program (XLYC1907065).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, J., Deng, J., Peng, W. et al. Strip Crown Prediction in Hot Rolling Process Using Random Forest. Int. J. Precis. Eng. Manuf. 22, 301–311 (2021). https://doi.org/10.1007/s12541-020-00454-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-020-00454-1