Abstract

The current knowledge and building code recommendations for bond behavior between concrete and embedded steel reinforcement become unwarranted when casting takes place in humid or fully submerged water conditions. The main objective of this paper is to assess the effect of underwater casting on the concrete mechanical and bond properties, including the development of regression models that simplify prediction of washout loss and corresponding bond stress-slip properties. Washout loss was determined using the standard CRD C61 test method and air-pressurized tube that simulates higher hydrostatic water pressure. Particular care was placed to reuse the same washed concrete samples for determining the residual compressive strength and bond properties to embedded steel bars. Test results showed that the washout loss and hydrostatic casting depth are directly affected by the concrete composition. Hence, for example, the decrease in water-to-cement ratio and/or addition of anti-washout admixture or silica fume improved concrete cohesiveness and resistance to washout. The stiffness and confinement of steel bars normally achieved in dry conditions curtailed with underwater casting, which led to reduced ductility and ultimate bond strength at failure. The experimental bond stress-slip data are compared with the CEB-FIP Code models and design strengths specified by ACI 318-19 and European Code EC-2. Regression analysis and predictive charts are established to facilitate assessing the effect of concrete composition on washout characteristics and residual strengths following underwater casting.

Similar content being viewed by others

Data Availability

As reported in the paper.

References

Jiang T, Wu Z, Huang L et al (2020) Three-dimensional nonlinear finite element modeling for bond performance of ribbed steel bars in concrete under lateral tensions. Int J Civ Eng. https://doi.org/10.1007/s40999-019-00488-1

Seara-Paz S, González-Fonteboa B, Eiras-López J et al (2004) Bond behavior between steel reinforcement and recycled concrete. Mater Struct 47:323–334. https://doi.org/10.1617/s11527-013-0063-z

Assaad J, Issa C (2017) Effect of recycled acrylic-based polymers on bond stress-slip behavior in reinforced concrete structures. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001700

ACI Committee 408 (2012) Bond and development of straight reinforcing bars in tension (ACI 408R-03) (reapproved 2012). American Concrete Institute, Farmington Hills, MI

ACI Committee 318-19 (2019) Building code requirements for reinforced concrete. American Concrete Institute, Farmington Hills, MI

EN 1992-1-1 (2004) Eurocode 2: design of concrete structures – part 1-1: general rules and rules for buildings. British Standards Institution, London

Federation Internationale du Beton (2010) The Int. Federation for structural concrete, model code 2010—final draft, volume 1, fib Bulletin No. 65. ISBN: 978-2-88394-105-2

Assaad JJ, Matar P, Gergess A (2020) Effect of quality of recycled aggregates on bond strength between concrete and embedded steel reinforcement. J Sustain Cem Based Mater 9(2):94–111. https://doi.org/10.1080/21650373.2019.1692315

McLeish A (1994) Underwater concreting and repairing. Taylor & Francis, London, p 160

Aminpour Y, Farhoudi J (2017) Similarity of local scour profiles downstream of stepped spillways. Int J Civ Eng 15:763–774. https://doi.org/10.1007/s40999-017-0168-9

Sonebi M, Khayat KH (1999) Effect of water velocity on the performance of underwater self-consolidating concrete. ACI Mater J 96(5):519–528

Khayat KH, Assaad JJ (2003) Relationship between washout resistance and rheological properties of high-performance underwater concrete. ACI Mater J 100(3):185–193

Assaad JJ, Gerges N, Khayat KH et al (2019) Assessment of bond strength of underwater polymer-modified concrete. ACI Mater J 116(6):1–10. https://doi.org/10.14359/51716982

Moon HY, Shin KJ (2006) Evaluation on steel bar corrosion embedded in antiwashout underwater concrete containing mineral admixtures. Cem Concr Res 36:521–529

Van der Wegen GJL, Bijen J, van Selst R (1993) Behaviour of concrete affected by sea-water under high pressure. Mater Struct 26(9):549–556. https://doi.org/10.1007/BF02472865

Assaad J, Daou Y, Khayat K (2009) Simulation of water pressure on washout on underwater concrete repair. ACI Mater J 106(6):529–536. https://doi.org/10.14359/51663336

ACI Committee 546.2R-10 (2010) Guide to underwater repair of concrete (ACI 546.2R-10). American Concrete Institute, Farmington Hills, MI, p 32

BS 8110 (2004) Structural use of concrete, part 1: code for practice for design and construction. British Standards Institution, London, UK, p 173

Assaad J, Issa C (2013) Effect of washout loss on bond behavior of steel embedded in underwater concrete. ACI Struct J 110(3):511–520. https://doi.org/10.14359/51685608

ASTM C33 (2003) Standard specification for concrete aggregates. ASTM, Philadelphia. https://doi.org/10.1520/C0033_C0033M-18

ASTM A615/A615 M (2020) Standard specification for deformed and plain carbon steel bars for concrete reinforcement. ASTM, Philadelphia. https://doi.org/10.1520/A0615_A0615M-20

CRD C61-89A (1989) Test method for determining the resistance of freshly-mixed concrete to washing out in water. Handbook for cement and concrete, U.S. Army Waterways Experiment Station, Vicksburg, MS, p 3

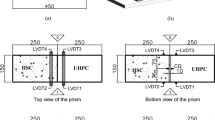

RILEM/CEB/FIB (1970) Bond test for reinforcing steel: 2, pullout test. Mater Struct 3(5):175–178

Issa C, Assaad J (2015) Bond of tension bars in underwater concrete – effect of bar diameter and cover. Mater Struct 48(11):3457–3471. https://doi.org/10.1617/s11527-014-0414-4

Mohemmi M, Broujerdian V, Rajaeian P (2020) An equivalent method for bar slip simulation in reinforced concrete frames. Int J Civ Eng. https://doi.org/10.1007/s40999-020-00507-6

Soltani A, Tarighat A, Varmazyari M (2018) Calcined marl and condensed silica fume as partial replacement for ordinary portland cement. Int J Civ Eng 16:1549–1559. https://doi.org/10.1007/s40999-018-0289-9

Sonebi M (2001) Factorial design modelling of mix proportion parameters of underwater composite cement grouts. Cem Concr Res 31:1553–1560. https://doi.org/10.1016/S0008-8846(01)00583-X

Assaad JJ, Matar P (2018) Regression models to predict SCC pressure exerted on formworks containing vertical and transverse reinforcing bars. Mater Struct. https://doi.org/10.1617/s11527-018-1188-x

Sueki S, Soranakom C, Mobasher B, Peled A (2007) Pullout-slip response of fabrics embedded in a cement paste matrix. J Mater Civ Eng 19(9):718–727

Ambrisi A, Feo L, Focacci F (2013) Experimental analysis on bond between PBO-FRCM strengthening materials and concrete. Compos Part B Eng 44(1):524–532

Haskett M, Oehlers DJ, Ali M (2008) Local and global bond characteristics of steel reinforcing bars. Eng Struct 30:376–383. https://doi.org/10.1016/j.engstruct.2007.04.007

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Assaad, J.J., Nasr, D., Gerges, N. et al. Use of Soft Computing Techniques to Predict the Bond to Reinforcing Bars of Underwater Concrete. Int J Civ Eng 19, 669–683 (2021). https://doi.org/10.1007/s40999-020-00598-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-020-00598-1