Abstract

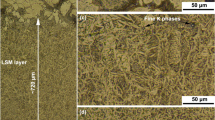

Herein, the friction stir processing (FSP) method was adopted to modify the microstructure of as-cast nickel aluminum bronze (NAB). The microhardness, cavitation erosion-corrosion mass loss, morphological damage and electrochemical tests were extensively examined. The results show that FSP can refine and uniform the microstructure of as-cast NAB alloy. FSP NAB alloy displays enhanced cavitation erosion resistance in distilled water and artificial seawater, as well as heightened sensitive to corrosive media in artificial seawater. Quantitative analysis of the synergistic effect between cavitation erosion and corrosion shows that pure cavitation erosion components contributions largest for as-cast NAB. In contrast, FSP NAB is greatly influenced by the synergistic effect component. The damaged surface shows that cavitation erosion mechanisms of as-cast NAB in distilled water and artificial seawater are similar, which is not the case for FSP NAB due to the synergistic effect between cavitation erosion and corrosion.

Graphic Abstract

Similar content being viewed by others

References

A.H. Tuthill, Mater. Perform. 26, 12–22 (1987)

A. Jahanafrooz, F. Hasan, G.W. Lorimer, N. Ridley, Metall. Trans. A 14, 1951–1956 (1983)

B. Aktas, O. Usta, M. Atlar, Appl. Ocean Res. 94, 101868 (2020)

M.S. Plesset, A. Prosperetti, Annu. Rev. Fluid Mech. 9, 145–185 (1977)

M. Blume, R. Skoda, Wear 428–429, 457–469 (2019)

E.A. Culpan, G. Rose, Brit. Corros. J. 14, 160–166 (1979)

Q.N. Song, Y.G. Zheng, D.R. Ni, Z.Y. Ma, Corros. Sci. 92, 95–103 (2015)

M. Hazra, K.P. Balan, Eng. Fail. Anal. 70, 141–156 (2016)

L.M. Zhang, A.L. Ma, H. Yu, A.J. Umoh, Y.G. Zheng, Tribol. Int. 136, 250–258 (2019)

Q.N. Song, N. Xu, Y. Tong, C.M. Huang, S.Y. Sun, C.B. Xu, Y.F. Bao, Y.F. Jiang, Y.X. Qiao, Z.Y. Zhu, Z.B. Wang, Acta Metall. Sin. Engl. 32, 1470–1482 (2019)

Q.N. Song, Y. Tong, N. Xu, S.Y. Sun, H.L. Li, Y.F. Bao, Y.F. Jiang, Z.B. Wang, Y.X. Qiao, Wear 450–451, 203258 (2020)

Z.B. Qin, Q. Zhang, Q. Luo, Z. Wu, B. Shen, L. Liu, W.B. Hu, Corros. Sci. 139, 255–266 (2018)

Y.T. Lv, L.Q. Wang, Y.F. Han, X.Y. Xu, W.J. Lu, Mater. Sci. Eng. A 643, 17–24 (2015)

Y.H. Zeng, F.F. Yang, Z.N. Chen, E.Y. Guo, M.Q. Gao, X.J. Wang, H.J. Kang, T.M. Wang, J. Mater. Sci. Technol. 61, 186–196 (2021)

B.J. Zhao, Y.T. Lv, Y. Ding, L.Q. Wang, W.J. Lu, Mater. Charact. 144, 77–85 (2018)

S. Hanke, A. Fischer, M. Beyer, J. dos Santos, Wear 273, 32–37 (2011)

R.C. Barik, J.A. Wharton, R.J.K. Wood, K.S. Tan, K.R. Stokes, Wear 259, 230–242 (2005)

K.-S. Park, S. Kim, J. Electrochem. Soc. 158, C335–C340 (2011)

R. Cottam, V. Luzin, H. Moody, D. Edwards, A. Majumdar, Y.C. Wong, J. Wang, M. Brandt, Wear 317, 56–63 (2014)

Q. Luo, Q. Zhang, Z.B. Qin, Z. Wu, B. Shen, L. Liu, W.B. Hu, J. Alloys Compd. 747, 861–868 (2018)

A. Jafari, M.H. Alam, D. Dastan, S. Ziakhodadadian, Z.C. Shi, H. Garmestani, A.S. Weidenbach, Ş. Ţălu, J. Mater. Sci. Mater. Electron. 30, 21185–21198 (2019)

R.S. Mishra, Z.Y. Ma, Mater. Sci. Eng. R 50, 1–78 (2005)

K. Oh-ishi, R. Mcnelley, Metall. Mater. Trans. A 35A, 2951–2961 (2004)

R.B. Naik, K.V. Reddy, G.M. Reddy, R.A. Kumar, Fusion Eng. Des. 161, 111962 (2020)

A. Moaref, A. Rabiezadeh, Trans. Nonferrous Met. Soc. 30, 972–981 (2020)

Y.T. Lv, B. Nie, L.Q. Wang, H.Z. Cui, L. Li, R. Wang, F.Y. Lyu, Mater. Sci. Eng. A 771, 138577 (2020)

D.R. Ni, B.L. Xiao, Z.Y. Ma, Y.X. Qiao, Y.G. Zheng, Corros. Sci. 52, 1610–1617 (2010)

S. Thapliyal, D.K. Dwivedi, Tribol. Int. 97, 124–135 (2016)

Q.N. Song, Y.G. Zheng, S.L. Jiang, D.R. Ni, Z.Y. Ma, Corrosion 69, 1111–1121 (2013)

M. Liu, C.Y. Li, L. Liu, Y.J. Ye, D. Dastan, H. Garmestani, Mater. Sci. Technol. 36, 284–292 (2020)

D1141-98 (Reapproved 2013), Standard Practice for the Preparation of Substitute Ocean Water (ASTM International, West Conshohocken, PA, 2013)

F. Hasan, A. Jahanafrooz, G.W. Lorimer, N. Ridley, Metall. Trans. A 13, 1337–1345 (1982)

L. Liu, Y.Y. Sheng, M. Liu, M. Dienwiebel, Z.C. Zhang, D. Dastan, Tribol. Int. 140, 105727 (2019)

Q.N. Song, Y.G. Zheng, D.R. Ni, Z.Y. Ma, Corrosion 71, 606–614 (2015)

H.X. Guo, B.T. Lu, J.L. Luo, Electrochim. Acta 51, 5341–5348 (2006)

Acknowledgments

The authors gratefully acknowledge the financial support provided by the National Natural Science Foundation of China (Grant No. 51705125), the Natural Science Foundation of Hebei Province (Grant No. E2020402005), the Science and Technology Research Project of Hebei Higher Education Institutions (Grant No. QN2017030), and the Science and Technology Research and Development Program Projects of Handan Science and Technology Bureau (Grant No. 1521109072-4).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Lian, Y. & Sun, Y. Synergistic Effect Between Cavitation Erosion and Corrosion for Friction Stir Processed NiAl Bronze in Artificial Seawater. Met. Mater. Int. 27, 5082–5094 (2021). https://doi.org/10.1007/s12540-020-00916-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00916-1