Abstract

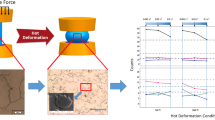

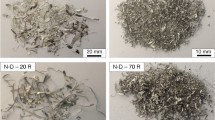

Carbide precipitates are effective for improving the strength and stability of high-entropy alloys. In this work, novel-designed Fe60Co10Cr10Ni10Mo5V5 medium-entropy alloys (MEAs) containing 1 wt.% carbon were prepared by vacuum arc melting followed by solid solution treatment and aging. The effects of aging on the microstructure and mechanical properties of the MEAs were investigated. The results showed that the microstructure of the solution-treated alloy was comprised of the face-centered cubic (FCC) matrix, coarse M2C/MC carbides, and tiny fine undissolved MC precipitates distributed on the grain boundaries and inside the grains. A high number density of cube-shaped MC precipitates, with an approximate mean size of 24 nm precipitate within the FCC matrix in the case of aging at 800°C for 2 h, contribute to the highest hardness and tensile strength of the sample without sacrificing its elongation. With increasing aging temperature and time, the size of the MC precipitates increased while their volume fraction decreased. The strengthening effect can be attributed to the combination of the precipitation strengthening and solid solution strengthening.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

B. Cantor, I. Chang, P. Knight, and A. Vincent, Mater. Sci. Eng., A 375–377, 213 (2004).

T. Yang, Y.L. Zhao, Y. Tong, Z.B. Jiao, J. Wei, J.X. Cai, X.D. Han, D. Chen, A. Hu, J.J. Kai, K. Lu, Y. Liu, and C.T. Liu, Science 362, 933 (2018).

Z. Wu, H. Bei, G.M. Pharr, and E.P. George, Acta Mater. 81, 428 (2014).

G. Laplanche, A. Kostka, C. Reinhart, J. Hunfeld, G. Eggeler, and E.P. George, Acta Mater. 128, 292 (2017).

J.Y. He, C. Zhu, D.Q. Zhou, W.H. Liu, T.G. Nieh, and Z.P. Lu, Intermetallics 55, 9 (2014).

G. Laplanche, P. Gadaud, C. Bärsch, K. Demtröder, C. Reinhart, J. Schreuer, and E.P. George, J. Alloys Compd. 746, 244 (2018).

W.H. Liu, Y. Wu, J.Y. He, T.G. Nieh, and Z.P. Lu, Scr. Mater. 68, 526 (2013).

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle, and C.F. Woodward, J. Alloys Compd. 509, 6043 (2011).

D. Ikeuchi, D.J. King, K.J. Laws, A.J. Knowles, R.D. Aughterson, G.R. Lumpkin, and E.G. Obbard, Scr. Mater. 158, 141 (2019).

Y. Zou, S. Maiti, W. Steurer, and R. Spolenak, Acta Mater. 65, 85 (2014).

H. Huang, Y. Wu, J. He, H. Wang, X. Liu, K. An, W. Wu, and Z. Lu, Adv. Mater. 29, 1701678 (2017).

N.D. Stepanov, N.Y. Yurchenko, S.V. Zherebtsov, M.A. Tikhonovsky, and G.A. Salishchev, Mater. Lett. 211, 87 (2018).

M. Feuerbacher, M. Heidelmann, and C. Thomas, Mater. Res. Lett. 3, 1 (2015).

A. Takeuchi, K. Amiya, T. Wada, K. Yubuta, and W. Zhang, JOM 66, 1984 (2014).

Y.J. Zhao, J.W. Qiao, S.G. Ma, M.C. Gao, H.J. Yang, M.W. Chen, and Y. Zhang, Mater. Des. 96, 10 (2016).

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, and R.O. Ritchie, Science 345, 1153 (2014).

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, and C.T. Liu, Acta Mater. 116, 332 (2016).

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, and Z.P. Lu, Acta Mater. 102, 187 (2016).

W.H. Liu, J.Y. He, H.L. Huang, H. Wang, Z.P. Lu, and C.T. Liu, Intermetallics 60, 1 (2015).

R. Zhou, Y. Liu, B. Liu, J. Li, and Q.H. Fang, Intermetallics 106, 20 (2019).

N. Gao, D.H. Lu, Y.Y. Zhao, X.W. Liu, G.H. Liu, Y. Wu, G. Liu, Z.T. Fan, Z.P. Lu, and E.P. George, J. Alloys Compd. 792, 1028 (2019).

C. Scott, B. Remy, J.L. Collet, A. Cael, C. Bao, F. Danoixd, B. Malardc, and C. Curfse, Int. J. Mater. Res. 102, 538 (2011).

R.A. Mesquita, C.A. Barbosa, E. Morales, and H.J. Kestenbach, Metall. Mater. Trans. A 42, 461 (2011).

H. Wang, L. Hou, J. Zhang, L. Lu, H. Cui, and J. Zhang, Mater. Charact. 106, 245 (2015).

M.J. Yao, K.G. Pradeep, C.C. Tasan, and D. Raabe, Scr. Mater. 72–73, 5 (2014).

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan, Nature 534, 227 (2016).

J.W. Bae, J.B. Seol, J. Moon, S.S. Sohn, M.J. Jang, H.Y. Um, B. Lee, and H.S. Kim, Acta Mater. 161, 388 (2018).

P. Ou, H. Xing, and J. Sun, Metall. Mater. Trans. A 46, 1 (2015).

X.F. Zhou, W.T. Li, H.B. Jiang, F. Fang, Y.Y. Tu, and J.Q. Jiang, Metall. Mater. Trans. A 50, 1682 (2019).

Z.B. Jiao, J.H. Luan, Z.W. Zhang, M.K. Miller, and C.T. Liu, Scr. Mater. 87, 45 (2014).

Z.W. Wang, I. Baker, Z.H. Cai, S. Chen, J.D. Poplawsky, and W. Guo, Acta Mater. 120, 228 (2016).

Acknowledgements

This research was financially supported by the Scientific Research Project Fund of Jiangxi Provincial Education Department (Grant Number GJJ180479), Open Foundation of State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing (Grant Number 2018-Z01), Key Research and Development Project of Jiangxi Province (Grant Number 2019BBEL50016), Natural Science Foundation of Jiangxi Province (Grant Number 20202BABL204010), and Program of the University Students’ Innovation and Pioneering (Grant No. DC2019-034).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, H., Hong, D., Hou, L. et al. Precipitation Behavior of Carbide and its Effect on the Mechanical Properties of a Novel Fe60Co10Cr10Ni10Mo5V5 Medium-Entropy Alloy. JOM 73, 668–678 (2021). https://doi.org/10.1007/s11837-020-04528-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04528-3