Abstract

Large and sensitive magnetostriction (large strain induced by small magnetic fields) is highly desired for applications of magnetostrictive materials. However, it is difficult to simultaneously improve magnetostriction and reduce the switching field because magnetostriction and the switching field are both proportional to the magnetocrystalline anisotropy. To solve this fundamental challenge, we report that introducing tetragonal nanoprecipitates into a cubic matrix can facilitate large and sensitive magnetostriction even in random polycrystals. As exhibited in a proof-of-principle reference, Fe–Ga alloys, the figure of merit—defined by the saturation magnetostriction over the magnetocrystalline anisotropy constant—can be enhanced by over 5-fold through optimum aging of the solution-treated precursor. On the one hand, the aging-induced nanodispersive face-centered tetragonal (FCT) precipitates create local tetragonal distortion of the body-centered cubic (BCC) matrix, substantially enhancing the saturation magnetostriction to be comparable to that of single crystal materials. On the other hand, these precipitates randomly couple with the matrix at the nanoscale, resulting in the collapse of net magnetocrystalline anisotropy. Our findings not only provide a simple and feasible approach to enhance the magnetostriction performance of random polycrystalline ferromagnets but also provide important insights toward understanding the mechanism of heterogeneous magnetostriction.

Similar content being viewed by others

Introduction

Magnetostrictive materials that can convert magnetic energy into mechanical energy or vice versa have been widely used in actuators, transducers, sensors, and energy harvesters1,2,3. For most applications, it is desirable to have a combination of large strain and a small switching field (which can be evaluated by the critical field, at which d33 reaches a maximum4, and is proportional to K/Ms for random polycrystals, where K is the magnetocrystalline anisotropy constant and Ms is the saturation magnetization5). However, it is difficult to simultaneously obtain a large magnetostriction and small switching field in a homogeneous ferromagnet because both the magnetostriction and switching fields are proportional to the magnetocrystalline anisotropy (MCA)1. There is one exception: combining two terminals with large magnetostriction but opposite MCA constants can yield large magnetostriction with reduced switching fields at a specific composition/temperature, as found in the well-known pseudobinary intermetallic compounds RR′Fe2 (R and R′ refer to two rare earth elements)2,6,7,8. When maximizing the magnetostriction for a given material, there is still a trade-off between a large magnetostriction and a small switching field, analogous to the strength-ductility trade-off in structural materials. The usual approach to maximize the magnetostriction of a given material with a large spontaneous magnetostriction constant has been fabricating a single crystal and further applying prestress or performing postgrowth magnetic annealing9,10,11. This complex process can constrain the ferromagnetic domains within the plane perpendicular to the crystal axis and can yield a large magnetostriction up to the theoretical limit through pure 90° domain switches when applying a magnetic field along the crystal axis. For decades, this approach has dominated the fabrication and application of the state-of-the-art magnetostrictive material Terfenol-D (e.g., Tb0.3Dy0.7Fe2) with a large rhombohedral spontaneous magnetostriction constant λ111 of 1640 ppm at room temperature2. The obtained technical strain λ//s along the field direction can be as high as 2400 ppm (nearly equivalent to the theoretical limit 3/2λ111) by applying compressive prestress on the single crystal11,12. However, a large magnetostriction is always obtained at the expense of an enlarged switching field (i.e., deteriorated sensitivity) because prestress and magnetic annealing inevitably induce additional anisotropy. Consequently, it is highly desirable to find a feasible approach that can enhance the magnetostriction and reduce the switching field simultaneously.

Several theoretical studies separately note that the exchange of nonequal crystallographic axes of the tetragonal strain nanodomains embedded within a cubic matrix will output large magnetostriction13, and the random magnetic coupling between them will result in the collapse of net MCA14,15. Experimentally, it is feasible to obtain such a nanostructured composite by aging a cubic supersaturated solid solution to form nanodispersive tetragonal precipitates, as extensively reported in structural alloys. In this work, we obtained ferromagnetic composites by isothermal aging of the metastable cubic precursor to precipitate nanodispersive tetragonal particles. Our results reveal that this can be a simple and feasible approach to obtain the desired large and sensitive magnetostriction in random polycrystals, as exhibited by the proof-of-principle reference Fe-Ga alloys.

The selection of Fe–Ga alloys takes into account the large magnetostriction at small fields and, in particular, the apparent structural differences between metastable and equilibrium states. In fact, Fe–Ga alloys have stimulated extensive research efforts since their large magnetostriction was discovered in 200016. As shown in two review papers17,18, previous research focused mainly on the compositions in the vicinity of 19 and 27 Ga at.%, at which two magnetostriction peaks have been reported19. The obtained λ//s of these two alloys has been successfully enhanced from ~60 ppm for random polycrystals16 to ~200 ppm for [001]-oriented single crystals or polycrystals20,21 and further to above 300 ppm (near the theoretical limit 3/2λ100) by applying a coaxial compressive prestress or by performing postgrowth magnetic/stress annealing9,10,21,22. More importantly, these two alloys bear an average body-centered cubic (BCC) structure in the quenched state but have biphase A2 + L12 (ordered face-centered cubic) for Fe81Ga19 and single L12 for Fe73Ga27 in the equilibrium state (see the phase diagram in Fig. S1)23. Since the L12 phase has negative magnetostriction (in contrast to the A2, B2 and D03 phases)24,25,26,27, approaching equilibrium conditions has been undesirable for achieving large positive magnetostriction. However, as shown hereinafter, short-term aging of the BCC precursor induces L60-type face-centered tetragonal (FCT) nanoprecipitates instead of the equilibrium L12 phase. The unique nanostructure with nanodispersive FCT precipitates embedded in the BCC matrix developed by optimum aging can create fivefold enhancement in the figure of merit due to the simultaneous magnetostriction enhancement and the collapse of net MCA. The obtained λ//s in the optimally aged Fe81Ga19 random polycrystal can reach as high as 200 ppm, which is comparable to that for single crystal materials measured under stress-free conditions20,21.

Materials and methods

Ingots with nominal compositions of Fe81Ga19 and Fe73Ga27 were prepared by induction melting Fe and Ga with purities of 99.99% in an argon atmosphere. Cylindrical rods were prepared by subsequent casting into a steel mold with an inner diameter of 12 mm. The rods were sealed in quartz tubes filled with high-purity argon and subjected to heat treatment. The metastable BCC precursors were obtained by annealing the rods for 72 h at 1373 K, followed by quenching in ice water. An electron back-scattered diffraction (EBSD, HITACHI-SU3500) image of the 1373 K-quenched sample revealed randomly oriented grains of several hundred microns (Fig. S2). The Fe73Ga27 and Fe81Ga19 rods were then cut into different sections (Ø 12 × 20 mm3) and aged at 723 K or 673 K, followed by quenching in ice water.

Note that during aging, the Fe–Ga alloys undergo a diffusion-controlled phase transformation25,26,27, after which the microstructure has a strong surface effect. To avoid the surface effect, sheets with dimensions of 10 × 3 × 1.5 mm3 were cut from the center sections of the aged rods (the length direction was parallel to the rod axis) and subjected to the following magnetostriction measurements and microstructural characterizations. Room temperature initial magnetization curves were measured using a SQUID magnetometer, which allows us to calculate the MCA constant K1 and saturation magnetization Ms according to the law of approaching saturation. Magnetostriction along the magnetic field direction was measured at room temperature using the strain gauge method. The strain gauge had a length of 1 mm and a width of 1.5 mm (KYOWA, KFR-1-120-C1-11), which was much larger than the grain size of several hundred microns for the solution-treated sample (Fig. S2) and several microns for the overaged samples. To avoid possible stress-induced impurities, the sample surface was carefully polished by standard mechanical grinding and electropolishing methods. At least five magnetization cycles (one cycle refers to increasing the magnetic field from zero to a designed strength, decreasing it to zero, then increasing the opposite magnetic field to the same designed strength, and finally decreasing it to zero) were measured for each sample. In addition, a random polycrystalline Fe72Ga28 alloy was selected as another reference to reproduce the aging effect on magnetostriction properties. Nanoindentation (G200) and atomic force microscopy (AFM) were conducted on the polished surfaces to investigate the modulus difference between the nanoprecipitates and the matrix. The foils for TEM characterization were prepared by twin-jet electropolishing at temperatures below 243 K. TEM characterizations were performed using a JEOL JEM-2100F microscope at 200 kV. The high-resolution TEM (HRTEM) images and geometric phase analysis (GPA) were analyzed using DigitalMicrograph (Gatan). Magnetic domain structures were observed under the Fresnel Lorentz mode. An in-plane magnetic field was applied to observe the domain structure evolution. The optimally aged Fe73G27 sample (cut into sheets with dimensions of 10 × 10 × 1.5 mm3) was subjected to in situ small-angle neutron scattering (SANS) measurements using unpolarized neutrons with a wavelength of 5.3 Å, which was performed on the small-angle neutron spectrometer at the China Mianyang Research Reactor (CMRR). An in-plane magnetic field was applied along the length direction.

Results and discussion

Aging-time-dependent magnetostriction and microstructure

Figures 1 and 2 show the magnetostriction and magnetization curves of the Fe73Ga27 and Fe81Ga19 samples, respectively. Both alloys exhibit similar aging-time-dependent magnetostrictions. In the solution-treated state, the saturation magnetostriction along the field direction (λ//s) for both alloys is 50–65 ppm (varies with composition), which is comparable to the values for Fe–Ga random polycrystals reported by Clark et al.16. After isothermal aging, the magnetostriction first increases to a peak value and then decreases to nearly zero or negative values with increasing aging time. Figure 1a shows the aging-time-dependent λ//s for Fe73Ga27 random polycrystals, where λ//s increases significantly from 65 ppm for the 1373 K-quenched state to 172 ppm for the one aged for 1 h at 723 K but gradually decreases to −75 ppm for the one aged for 12 h. Representative magnetostriction curves are shown in Fig. 1b. The highest magnetostriction λ//s for the Fe81Ga19 alloy is 202 ppm after aging for 8 h at 673 K, ~4 times that for the solution-treated state (Fig. 2). Further magnetostriction measurements on the Fe72Ga28 random polycrystalline samples reproduce this aging time dependence (Fig. S3). More importantly, the obtained 202 ppm magnetostriction is comparable to that for a single crystal measured under stress-free conditions20,21 and surpasses the reported values in bulk Fe-Ga random polycrystals doped with a third element, such as Cr, Mn, Co, Dy, or Tb19,28,29,30,31, as shown in Fig. 2d. Therefore, short-term isothermal aging is a simple and feasible approach to achieve large magnetostriction in Fe–Ga random polycrystals without doping with any expensive and scarce metals or the need to grow single crystals on a special instrument.

a, b Magnetostriction curves and initial magnetization curves for Fe81Ga19 with different heat treatments. The inset in b is the aging time dependence of the magnetocrystalline anisotropy constant K1. c Figure of merit of magnetostriction as a function of aging time for the Fe81Ga19 random polycrystals. d Comparison of λ//s among our optimally aged Fe–Ga random polycrystals, the single crystals (measured under stress-free conditions20,21) and the quenched random polycrystals doped with a third element in refs. 19,28,29,30,31.

Isothermal aging also results in the collapse of the net MCA, thereby significantly enhancing the figure of merit, as shown in Fig. 2c. The MCA constant K1 calculated according to the law of approaching saturation exhibits a nonlinear dependence on aging time. K1 for the 1 h-aged Fe73Ga27 sample and the 8 h-aged Fe81Ga19 sample is even smaller than that for the 1373 K-quenched sample, which is unusual for a homogeneous ferromagnet since a larger magnetostriction should result from strengthened MCA1. The reduced K1 (collapse of net MCA) indicates that the alloys become much softer after optimum aging. The figure of merit can be defined by │λ//s/Hs│32 or │λ//s/K1│33 or │λ//s/Hc│7, where Hs is the magnetostriction saturation field and Hc is the coercivity. Since both Hs and Hc are proportional to │K1│for random polycrystalline ferromagnets, here, we use │λ//s/K1│to evaluate the figure of merit of the Fe-Ga random polycrystals. The │λ//s/K1│ for the optimally aged Fe81Ga19 sample is nearly 5 times larger than that of the quenched state, as shown in Fig. 2c. This means that after optimum aging, the magnetostriction becomes more sensitive, i.e., it is very easy to achieve large and sensitive magnetostriction. In addition, the 1 h-aged Fe73Ga27 sample exhibits only 3.2% higher saturation magnetization Ms than the 1373 K-quenched sample (Fig. 1b) but 186.7% larger λ//s. This is also against conventional wisdom for homogeneous ferromagnets because │λs│ is proportional to Ms31.

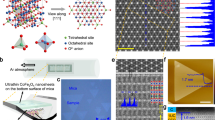

Figure 3 shows bright-field images and the corresponding selected area electron diffraction (SAED) patterns of the Fe73Ga27 samples with different heat treatments. The superlattice reflections at the {200}* positions suggest that the BCC phase is ordered at the as-quenched state (Fig. 3d). According to previous studies26,34, this state contains a relatively large fraction of the D03 phase in addition to the disordered A2 phase. After aging for 1 h at 723 K, randomly distributed nanoprecipitates are formed (Fig. 3b). Most nanoprecipitates have a similar size of ~20 nm, whereas few have a size of ~80 nm. These nanoprecipitates produce additional superlattice reflections around the {110}*-D03 positions that are excluded for A2, B2 or D03, as indicated by the red arrows in Fig. 3e. After aging for 12 h at 723 K, the nanoprecipitates transform into L12 with a mean grain size of ~1 μm (Fig. 3c, f).

Figure 4a shows a typical HRTEM image taken along the [001] zone axis (ZA) of the 1 h-aged Fe73Ga27 sample. Region I has the D03 structure. However, the FFT pattern of region II displays additional superlattice reflections around the {110}*-D03 positions, as indicated by the red arrows. These extra superlattice reflections can be indexed as (010), (100), \(\left( {0\overline {\mathrm{1}} 0} \right)\) and \(\left( {\overline {\mathrm{1}} 00} \right)\) spots for an FCT L60-type structure, according to the Bain orientation relationship [001]-FCT//[001]-D03 and (200)-FCT//(220)-D03. Along [111] ZA, the FCT nanoprecipitates produce additional superlattice reflections around the \(\left( {\bar 110} \right)\)-D03 and \(\left( {\bar 1\bar 12} \right)\)-D03 positions (Fig. 4d), which can be indexed as (010)-FCT and \(\left( {\bar 101} \right)\)-FCT, following the Bain orientation relationship [111]-D03//[101]-FCT and \(\left( {\bar 202} \right)\)-D03//\(\left( {\bar 111} \right)\)-FCT. Along [110] ZA, the FCT nanoprecipitates produce additional superlattice reflections around the \(\left( {\bar 110} \right)\)-D03 and \(\left( {\bar 112} \right)\)-D03 positions (Fig. 4g), which can be indexed as (010)-FCT and (011)-FCT, following the Bain orientation relationship [110]-D03//[100]-FCT and \(\left( {\bar 220} \right)\)-D03//(020)-FCT. It should be noted that the L60-type FCT structure is alternatively a body-centered-tetragonal (BCT)-modified D03 structure, as suggested by Lograsso et al.35. The obtained FFT patterns are consistent with the simulated patterns for the modified D03 structure, as reported by Jiang et al.36,37,38. L60-type nanoprecipitates are also observed in the 8 h-aged Fe81Ga19 alloy (Fig. S4).

HRTEM image, selected area FFT patterns, and IFFT images of the 1 h-aged Fe73Ga27 sample along the a–c [001], d–f [111], and g–i [110] ZAs. The IFFT images in (c), (f) and (i) were taken from the matrix using the (040), \(\left( {0\overline {\mathrm{4}} 0} \right)\), (400), \(\left( {\overline {\mathrm{4}} 00} \right)\) reflections; \(\left( {\overline {\mathrm{2}} 20} \right)\), \(\left( {2\overline {\mathrm{2}} 0} \right)\), \(\left( {\overline {\mathrm{2}} 02} \right)\), \(\left( {20\overline {\mathrm{2}} } \right)\) reflections; and (004), \(\left( {00\overline {\mathrm{4}} } \right)\), \(\left( {\overline {\mathrm{2}} 20} \right)\), \(2\overline {\mathrm{2}} 0\) reflections, respectively.

An important conclusion can then be drawn: the short-term aging-induced substantial magnetostriction enhancement is attributed to the formation of L60-type nanoprecipitates, and the overaging-induced magnetostriction deterioration is due to the further transformation into the L12 phase with intrinsic negative magnetostriction. It should be noted that, in the past, the quenched state has been believed to exhibit the largest magnetostriction, and approaching the equilibrium state (e.g., slow cooling or increasing aging time) will deteriorate the magnetostriction39,40,41. Numerous investigations have shown that slow cooling will promote the ordering of the D03 phase and/or the precipitation of the L12/D019 phases, which are detrimental to magnetostriction performance34,42,43,44. For instance, A.K. Mohamed et al. recently showed that the A2 → D03 + A2′ transition will occur above 673 K with cooling rates of 2–30 K/min and that the L12 phase will appear with cooling rates ≤2 K/min in Fe80.5Ga19.5 alloys43. On the other hand, long-term aging within the L12 phase regime will lead to a large fraction of the L12 phase and deteriorate magnetostriction24,27,45. For instance, the magnetostriction of the Fe72.4Ga27.6 alloy decreases from 105 to 30 ppm when the 50 vol.% L12 phase is formed27. However, the present work reveals that placing Fe–Ga alloys at a proper intermediate state between the metastable and equilibrium states (e.g., short-term aging) should be the optimum condition to maximize magnetostriction, owing to the formation of dispersive L60 nanoprecipitates. The role of L60 nanoprecipitates in enhancing magnetostriction will be discussed in the next section.

Role of FCT nanoprecipitates

Note that the formation of the L12 phase requires simultaneous atomic migration (by aligning Ga–Ga pairs along the [001] direction) and drastic lattice distortion (simultaneous elongation along the [001] axis by 25.9% and contractions along the [100] and [010] axes by −11.1%) of the metastable BCC phases26,46; thus, it has slow kinetics. Therefore, the transformation process and the product phase are largely affected by the competition between the strain energy and interfacial energy. In the early transformation stage, given that the atomic positions within the nanoprecipitates have been altered to fit the L12 lattice, the lattice distortion will be constrained by the surrounding matrix because of the limited size. As shown in Fig. 3, the extra superlattice reflections of the L60 nanoprecipitates indicate that the atomic position exchanges occur at local regions; however, the lattice parameters are not fixed for the equilibrium L12. For instance, the calculated tetragonality (c/a) for the FCT L60 nanoprecipitates is 0.712 in Fig. 4e, h, which is slightly greater than 1/\(\sqrt {2}\) for an ideal BCC structure and much smaller than 1 for an ideal FCC structure. In this case, the L60 nanoprecipitates can be deemed the constrained-L12 phase. The unit cells of D03, L60 and L12 Fe3Ga are shown in Fig. S5. Very recently, our work indicated that L60 nanoprecipitates have size-dependent tetragonality; the larger their size is, the greater the tetragonality (closer to 1 of the equilibrium L12 phase)47.

It should be noted that the BCC matrix has an open structure and that the L60 and L12 phases are more closely packed. The nanoindentation test revealed that the 1 h-aged sample yields the precipitation hardening effect due to the formation of L60 nanoprecipitates, which are mechanically harder than the BCC matrix (Fig. S6). The mutual elastic interaction between the harder L60 nanoprecipitates and the softer BCC phase locally distorts the surrounding matrix, although the formation of L60 multivariants reduces the net strain. One can see from the diffraction pattern in Fig. 3e that diffuse scattering of the fundamental reflections indicates local lattice distortion. More clearly, the lattice distortion is reflected by the splitting feature along the [100]* direction. As indicated by the red arrows in the bottom of Fig. 3e, the high-order fundamental reflection (12 00)-D03 in the 1 h-aged Fe73Ga27 sample splits into two weaker reflections. In contrast, the 1373 K-quenched and 12 h-aged samples do not have such apparent splitting features, as shown in the bottoms of Fig. 3d, f, respectively. Figure 4c shows a typical distorted region surrounding the L60 nanoprecipitate, which is an inverse FFT image created by taking the (040), \(\left( {0\overline {\mathrm{4}} 0} \right)\), (400), and \(\left( {\overline {\mathrm{4}} 00} \right)\) reflections. Local strain fluctuations can be seen from the inequivalent d spacings and between the (010) and (100) planes. Such lattice distortion is also observed along the [111]- and [110]-D03 zone axes, as shown in Fig. 4f, i, respectively. The local lattice distortion surrounding the nanoprecipitates is also verified by geometric phase analysis (Fig. S7). The local tetragonal distortion then gives rise to an apparent average tetragonality greater than 1 [splitting of the (12 00)-D03 reflection in the bottom of Fig. 3e], which means that the spontaneous magnetostriction constant λ001 of the matrix is effectively increased after short-term aging [compared with the (12 00)-D03 reflection without splitting in the bottom of Fig. 3d].

Figure 5a–f show the in-, over- and under-focus L-TEM Fresnel images of the 1373 K-quenched and 1 h-aged Fe73Ga27 samples, respectively. The bright and black lines are the 90° and 180° magnetic domain walls (DWs). The domain of closure is observed for the 1373 K-quenched sample. Interestingly, after aging for 1 h, magnetic DWs are observed at the phase interfaces (marked by the red arrows in Fig. 5e). Such DWs are due to the domain wall energy density difference between the matrix and L60 nanoprecipitates. Unlike the straight and well-ordered samples for the 1373 K-quenched sample, after aging, the DWs transform into serpentine and irregularly shaped configurations. This indicates that the L60 nanoprecipitates are magnetically coupled with the matrix phase. The irregular magnetic domain configurations of the matrix are the result of the collapse of net anisotropy, which stems from the competition between the coherent anisotropy and the random anisotropy of the L60 nanoprecipitates15. Figure 5g–i show in situ L-TEM images for the 1 h-aged Fe73Ga27 sample. When a small magnetic field of 0.006 T (60 Oe) is applied, the magnetic DWs of some L60 nanoprecipitates disappear and the ferromagnetic domains of the matrix simultaneously rotate toward the field direction. When the magnetic field increases to 0.015 T (150 Oe), the DWs of the matrix disappear, whereas those of several L60 nanoprecipitates still exist. This indicates that the L60 nanoprecipitates with easy axes far away from the field direction are certainly more difficult to magnetize than those with easy axes close to the field direction.

We further performed in situ SANS measurements on the 1 h-aged Fe73Ga27 sample. Figure 6a–d show the original 2D SANS patterns detected in different magnetic fields. The contour of 2D patterns undergoes an isotropy-anisotropy-isotropy transition with increasing magnetic field. Figure 6e, f show the scattering intensity I(q) curves summed over the scattering vectors qx (parallel to H) and qy (perpendicular to H) from 2D patterns, respectively. In the I-qx curves (Fig. 6e), a broad peak is detected in the range of 0.1 nm−1 ≤ qx ≤ 0.3 nm−1 at 0 T, 0.05 T and 0.15 T; however, this peak disappears when the field increases to 0.5 T or 1.7 T. In the I–qy curves (Fig. 6f), a broad peak is also observed at 0 T and 0.05 T, whereas this peak disappears at fields above 0.15 T. This magnetic-field-dependent broad peak corresponds to inhomogeneous L60 nanoprecipitates. In the nanoprecipitate-matrix approximation48,49, the scattering intensity I(q) reflects the spatial fluctuations of scattering length density (SLD) for both nuclear and magnetic contributions. The nuclear contribution can be expressed as \(NV_p^2\left| {F(q)} \right|^2{\Delta} \rho _{{\mathrm{nuc}}}^2\), and the magnetic contribution can be expressed as \(NV_p^2\left| {F(q)} \right|^2{\Delta} \rho _{{\mathrm{mag}}}^2\)sin2α, where N stands for the number of nanoprecipitates; Vp is the volume of an individual nanoprecipitate with the form factor F(q); Δρnuc and Δρmag are the contrasts of nuclear and magnetic SLDs between the nanoprecipitates and the matrix, respectively; and α is the angle between q and the local magnetization vector in the nanoprecipitates.

The calculated nuclear SLD is ~7.2 × 10−6 Å−2 for both the BCC matrix and the L60 nanoprecipitates (Fig. S8), which is consistent with the value reported in the literature50. This indicates that there is no measurable nuclear contrast between the L60 nanoprecipitate and matrix. In addition, since the L60 nanoprecipitates formed by diffusive phase transformation cannot be decomposed by increasing the magnetic field, the magnetic-field-dependent broad peak is not attributed to their nuclear contrast but rather to the magnetic contrast between the L60 nanoprecipitates and the matrix. Under 1.7 T (at which the magnetization is saturated), all the magnetizations are parallel to the applied field direction, and the I–qy curve can then reflect the magnetic contribution due to the contrast of magnetic SLDs between the L60 nanoprecipitates and matrix. According to the fitting curve (Fig. S8a), the calculated average radius for the spherical nanoprecipitates is 9.7 ± 0.1 nm (consistent with the TEM observations) and the calculated Δρmag (the difference in magnetic SLDs between the L60 nanoprecipitates and matrix) is ~4.0 × 10−7 Å. We further calculated the magnetic SLD for the BCC matrix and the L60 nanoprecipitates, which is 2.9 × 10−6 Å−2 and 3.3 × 10−6 Å−2, respectively.

The distinct feature between the I–qx and I–qy curves at 0.15 T can correlate the magnetization flips of the L60 nanoprecipitates with the magnetostriction since the magnetostriction is nearly saturated in this field (Fig. 1b). The magnetization process of the 1 h-aged Fe73Ga27 sample can be derived from the in situ characterizations, as schematically illustrated in Fig. 6g–i. For ease of understanding, the nanoprecipitates with the c-axis parallel (or close) and perpendicular to (or far away from) H are defined as L60// and L60⊥, respectively. According to the observations of the DWs surrounding the L60 nanoprecipitates in Fig. 5e, g, the directions of spontaneous magnetizations for the tetragonal L60 nanoprecipitates are distinct from the surrounding BCC matrix phase at the thermally demagnetized state (0 T). Determined from the factor sin2α in the form \(NV_p^2\left| {F(q)} \right|^2{\Delta} \rho _{{\mathrm{mag}}}^2\)sin2α, the peak in the I–qx curve arises from the magnetic contrast between the magnetizations of the L60⊥ nanoprecipitates and the vertical components of the matrix magnetizations. The peak in the I–qy curve then arises from the magnetic contrast between the magnetizations of the L60// nanoprecipitates and the parallel components of the matrix magnetizations. According to the literature51,52, the different magnetization directions of the nanoprecipitates and matrix can engender strong magnetic scattering. When the field increases to 0.15 T (Fig. 6h), the magnetizations in the L60// nanoprecipitates flip toward H together with the rotation of the ferromagnetic domains of the matrix. This results in magnetic contrast collapse in the I–qy curve, i.e., the disappearance of the peak at 0.15 T. Moreover, the magnetizations of the L60⊥ nanoprecipitates remain far from H since the peak still exists in the I–qx curve, indicating that 0.15 T is not sufficiently strong to switch the magnetizations of the L60⊥ nanoprecipitates along the field direction, which is consistent with the L-TEM observation in Fig. 5i, where the DWs of the matrix disappear and those of several L60 nanoprecipitates still exist. Following the literature48,49, the field dependence of the aspect ratio of scattering intensity [I(qy)/I(qx)] summed within the peak range (0.1 nm−1 < q < 0.3 nm−1) is plotted in Fig. S8b. Since the magnetizations of the L60// and L60⊥ nanoprecipitates may simultaneously rotate with the ferromagnetic domains of the matrix, the aspect ratio will increase with increases in the magnetic field owing to the increased magnetic scattering in the direction perpendicular to the field. However, the aspect ratio gradually decreases to ~0.36 as the field increases to 0.15 T, which confirms the nonuniform flipping of the magnetizations of the L60// and L60⊥ nanoprecipitates. The increased magnetic contrast between the magnetizations of the L60⊥ nanoprecipitates and the vertical components of the matrix magnetizations gives rise to the relatively enhanced scattering intensity for I–qx, and the reduced magnetic contrast between the magnetizations of the L60// nanoprecipitates and the parallel components of the matrix magnetizations gives rise to the relatively decreased scattering intensity for I–qy. When the field further increases to 0.5 T (Fig. 6i), the magnetizations of the L60⊥ nanoprecipitates are also nearly oriented along the field direction, as determined from the magnetic contrast collapse in the I-qx curve and the further increase in the aspect ratio (Fig. S8b). Such results indicate that the large magnetostriction generated below 0.15 T arises mainly from the magnetization flips of the ferromagnetic domains of the matrix and the L60// nanoprecipitates. Considering that the magnetization flips of the L60⊥ nanoprecipitates should result in larger magnetostriction than those of the L60// ones, the SANS measurements then exclude the contribution of the magnetization flips of the L60⊥ nanoprecipitates to the large magnetostriction obtained in the present Fe–Ga alloys.

Discussion

The present findings may have important implications.

First, this work may provide important insights toward understanding the microstructure origin of the large magnetostriction in Fe–Ga alloys. In fact, it is still an open question why soluting nonmagnetic Ga into Fe can induce a significant magnetostriction enhancement. In particular, intrinsic factors, namely, Ga-induced changes in the electronic structures of the A2 solid solution, were proposed to explain this phenomenon53,54,55. Note that Fe–Ga alloys are inherently heterogeneous at the nanoscale. Both macroscopic and local techniques have identified that in addition to the A2 matrix26,34,35,36,37,38,56,57, quenched Fe–Ga alloys also contain short-range-ordered Ga–Ga pairs (<2 nm), forming cubic D03 nanoprecipitates with Ga–Ga pairs along the <110> axis of the A2 matrix and/or tetragonal L60-type nanoprecipitates with Ga–Ga pairs along the <001>BCC axis. It is clear that the cubic D03 nanoprecipitates are detrimental since slow cooling promotes the long-range-ordering of the D03 phase and deteriorates magnetostriction39,40,41,42. It was shown that proper heat treatment can avoid the formation of D03 nanoprecipitates, thereby effectively enhancing the magnetostriction of Fe-Ga alloys. For instance, λ//s of the Fe81Ga19 alloy can be enhanced by 71.4% when quenched near the phase boundary between A2 and (A2 + L12) after slow cooling (free of D03 nanoprecipitates), in comparison with the D03-bearing sample quenched at high temperature (1273 K)58. Comparably, the present approach of short-term aging can provide a more significant magnetostriction enhancement (e.g., magnetostriction increased 3-fold after aging the Fe81Ga19 alloy for 8 h), given that harmful D03 ordering occurs simultaneously with the formation of L60 nanoprecipitates. This indicates that the L60-type nanoprecipitates should play an important role in enhancing magnetostriction in addition to the intrinsic factors. The present work contributes to finding a feasible approach to enlarge the size and enrich the population of L60-type nanoprecipitates that strongly affect the magnetostriction of Fe–Ga alloys, thus giving rise to substantial magnetostriction enhancement. In addition, our work also helps to understand why L60-type nanoprecipitates form in Fe–Ga alloys. During rapid cooling, the high vacancy density leads to the short-range-ordering of Ga–Ga pairs along the <001> direction, forming very fine L60 nanoprecipitates. When subjected to further aging, the fine L60 nanoprecipitates grow toward forming the L12 equilibrium phase, which requires simultaneous atomic position changes and lattice distortion of the matrix. In the early transformation stage, the L12 precursors are constrained at the nanoscale by the untransformed matrix. As the aging time extends, equilibrium L12 particles are preferably formed in local regions. Because of its intrinsic negative magnetostriction, it will offset the positive magnetostriction of the distorted matrix, leading to a decrease in net magnetostriction, as shown in Fig. 1. Consequently, the optimum condition to obtain large magnetostriction in Fe-Ga alloys is to form L60 nanoprecipitates in the intermediate state. It should also be noted that this diffusion-controlled phase transformation is highly sensitive to the material dimensions since the atomic diffusion rate is much faster at the material surface than at the internal material surface. When utilizing this strategy to obtain large magnetostriction in Fe–Ga alloys, the optimum aging time for a fixed composition depends on the sample size, for instance, the thickness of sheet samples. As shown in Fig. S9, after aging for 1 h at 723 K, the surface of a 1 mm-thick Fe73Ga27 sheet sample already contained mainly the L12 phase.

Second, this work provides important insights into the heterogeneous magnetostriction mechanism of ferromagnetic composites with nanoscale precipitation. Early investigations have suggested that the matrix surrounding the nanoprecipitates rather than the nanoprecipitates themselves is the source of the large magnetostriction of Fe-Ga alloys36,37,49,56. Within the tetragonal nanoprecipitate model proposed by Khachaturyan et al.59, the tetragonal nanoprecipitates rotate by realigning the c-axis or distort in concert with the much larger ferromagnetic domains, and elastic coupling of nanoprecipitates to the matrix results in large magnetostriction. Jiang et al.36 suggested that the nanoprecipitates already generated tetragonal distortion of the cubic matrix and that rotation of the matrix tetragonality results in large magnetostriction. Our work supports the local tetragonal distortion of the matrix. The distorted matrix shares a general morphology with premartensitic tweeds or unfrozen strain glass60,61,62, which contain a very fine mixture of variously oriented spontaneous strain states at the nanoscale. According to the model proposed by Seiner et al.61, reorientation of the premartensitic tweeds in Ni-Mn–Ga alloy can be easily induced by a small magnetic field with a magnetostriction of ~200 ppm. Similar low-field-triggered large magnetostriction has also recently been reported in ferromagnetic Fe–Pd strain glass with tetragonal strain nanodomains embedded in a cubic matrix32. The presently aged Fe–Ga alloys with local tetragonal distortion are new members of this family. In addition, our in situ SANS investigations suggested that the magnetization flips of the L60 nanoprecipitates (those with magnetizations perpendicular to the field direction) occur at high fields, thereby excluding their direct role in the large magnetostriction at low fields. A recent phase field simulation work37 is consistent with this experimental finding, in which the Ga-Ga pairs (along the [001] easy axis) of the L60 nanoprecipitates are fixed under magnetic fields.

Third, our work provides a feasible approach to overcome the trade-off between large magnetostriction and the small switching field of magnetostrictive materials. Although inducing uniaxial anisotropy by applying prestress or by magnetic annealing to redistribute the magnetic domains is effective in approaching the magnetostriction limit of a given material, it inevitably enlarges the switching field because the external field should first overcome the induced extra energy. The present work, which introduces mechanically harder tetragonal nanoprecipitates into a softer cubic matrix, overcomes this trade-off. On the one hand, the local tetragonal distortion of the matrix increases the spontaneous magnetostriction constant λ001, i.e., the average tetragonality of the matrix. This, can be determined from a comparison of diffraction spots between the as-quenched and optimally aged samples, as shown at the bottom of Fig. 3d, e. On the other hand, although the locally distorted regions or the tetragonal nanoprecipitates may have stronger local MCA than the ideal cubic matrix, the random magnetic coupling at the nanoscale between them and the matrix results in the collapse of net MCA. According to Cullen et al. 15, <001> Ga–Ga pairs can produce local uniaxial <001> anisotropy. The local regions with <001> Ga–Ga pairs were suggested to form the L60 (i.e., modified-D03) structure35,36. Our atomic-resolution STEM-HAADF Z-contrast image has directly shown that the L60 nanoprecipitates contain <001> Ga-Ga pairs47. It can then be concluded that the L60 nanoprecipitates have local uniaxial <001> anisotropy, with the [001] easy axis parallel to one of the six equivalent <001> directions ([001], [010], [100], \(\left[ {00\bar 1} \right]\), \(\left[ {0\bar 10} \right]\), and \(\left[ {\bar 100} \right]\)) of the BCC matrix due to simultaneous precipitation in local regions. The competition between the coherent crystalline anisotropy of the matrix and the anisotropy created by the fluctuations in the magnetization due to the local uniaxial <001> anisotropy of the L60 nanoprecipitates then results in an instability of the <001> uniformly magnetized state and manifests itself by the vanishing anisotropy. Following this, the locally distorted regions (strain nanodomains) may play a similar role as the L60 nanoprecipitates. However, how the magnetic couplings among the strain nanodomains, the L60 nanoprecipitates and the undistorted matrix quantitively affect the net anisotropy calls for further study. Since random short-range magnetic coupling is also known to improve magnetic susceptibility14,63, the nanodispersive precipitates within the matrix can sensitively respond to low external fields, which accordingly reduces the switching field. With further development, this knowledge can be applied to obtain large sensitive magnetostriction in other nanostructured ferromagnets. We note that in Fe-Co alloys, quenching at the phase boundary between BCC and FCC can also create tetragonal nanoprecipitates, giving rise to larger and more sensitive magnetostriction when compared with the single BCC state3,64,65,66. Consequently, introducing dispersive tetragonal nanoprecipitates into a cubic matrix can be a universal approach to achieve large and sensitive magnetostriction. For engineering applications, heat treatment (short-term aging or quenching at specific temperatures) is a very simple approach when compared with single crystal growth and magnetic annealing approaches, which usually require special instruments and greater energy consumption. In addition, when compared with the approach of applying prestress, the present approach also has advantages in simplifying the design of magnetostriction-associated devices.

Conclusions

Our work provides a feasible approach to obtain large and sensitive magnetostriction in random polycrystalline ferromagnets by aging-induced nanodispersive precipitates. As shown in the proof-of-principle reference, Fe-Ga alloys, short-term isothermal aging of the BCC precursor can effectively introduce FCT L60 nanoprecipitates. Manipulating the size and density of the L60 nanoprecipitates significantly enhances the magnetostriction of the random polycrystals to be comparable to that for single crystal materials and effectively reduces the net magnetocrystalline anisotropy. The structural investigations reveal that the harder nanoprecipitates create local tetragonal distortion of the softer matrix (i.e., increasing the spontaneous tetragonal magnetostriction constant λ001), resulting in magnetostriction enhancement. In situ magnetic domain structure observations and SANS measurements reveal that random magnetic coupling at the nanoscale effectively improves the magnetic susceptibility, hence giving rise to a 5-fold enhancement in the figure of merit. These findings not only provide important insights toward understanding the microstructural origin of the extraordinary magnetostriction enhancement induced by soluting nonmagnetic Ga into Fe but also help to understand the heterogeneous magnetostriction mechanism. Aging-induced nanodispersive tetragonal precipitates within a cubic matrix can be a feasible approach to achieve large and sensitive magnetostriction in ferromagnetic materials.

References

Chikazumi, S. Physics of Ferromagnetism (Oxford University Press, Oxford, UK, 2005).

Clark, A. E. Magnetostrictive rare earth-Fe2 compounds. Ferromagnetic Materials, 531–589 (North-Holland, Amsterdam, 1980).

Hunter, D. et al. Giant magnetostriction in annealed Co1-xFex thin-films. Nat. Commun. 2, 518 (2011).

Liu, J. H., Zhang, T. L., Wang, J. M. & Jiang, C. B. Giant magnetostrictive materials and their applications. Mater. China 31, 1–12 (2012).

Chopra, H. D., Yang, X. D. & Wilson, P. Magnetoelastic dependence of switching field in TbFe-FeCo giant magnetostrictive spring-magnet multilayers. J. Appl. Phys. 87, 5780–5782 (2000).

Atzmony, U. et al. Magnetic anisotropy and spin rotations in HoxTb1-xFe2 cubic Laves compounds. Phys. Rev. Lett. 28, 244–247 (1972).

Yang, S. et al. Large magnetostriction from morphotropic phase boundary in ferromagnets. Phys. Rev. Lett. 104, 197201 (2010).

Bergstrom, Richard Jr et al. Morphotropic phase boundaries in ferromagnets: Tb1-xDyxFe2 alloys. Phys. Rev. Lett. 111, 017203 (2013).

Wun-Fogle, M., Restorff, J. B. & Clark, A. E. Magnetostriction of stress-annealed Fe-Ga and Fe-Ga-Al alloys under compressive and tensile stress. J. Intell. Mater. Syst. Struct. 17, 117–122 (2006).

Yoo, J.-H., Restorff, J. B., Wun-Fogle, M. & Flatau, A. B. The effect of magnetic field annealing on single crystal iron gallium alloy. J. Appl. Phys. 103, 07B325 (2008).

Zhang, C. S., Sun, G. A., Yan, M. & Ma, T. Y. Effect of the induced anisotropy axis on altering domain alignment and magnetostriction of Terfenol-D. Appl. Phys. Lett. 104, 052409 (2014).

Wu, G. H. et al. <111> oriented and twin-free single crystals of Terfenol-D grown by Czochralski method with cold crucible. Appl. Phys. Lett. 67, 2005–2007 (1995).

Rao, W. F. & Khachaturyan, A. G. Superfunctionalities in nanodispersive precipitation-hardened alloys. Phys. Rev. Lett. 109, 115704 (2012).

Chudnovsky, E. M., Saslow, W. M. & Serota, R. A. Ordering in ferromagnets with random anisotropy. Phys. Rev. B 33, 251–261 (1986).

Cullen, J., Zhao, P. & Wuttig, M. Anisotropy of crystalline ferromagnets with defects. J. Appl. Phys. 101, 123922 (2007).

Guruswamy, S., Srisukhumbowornchai, N., Clark, A. E., Restorff, J. B. & Wun-Fogle, M. Strong, ductile, and low-field-magnetostrictive alloys based on Fe-Ga. Scr. Mater. 43, 239–244 (2000).

Atulasimha, J. & Flatau, A. B. A review of magnetostrictive iron-gallium alloys. Smart Mater. Struct. 20, 043001 (2011).

Petculescu, G., Wu, R. & McQueeney, R. Magnetoelasticity of bcc Fe-Ga alloys. Handb. Magn. Mater. 20, 123–226 (2012).

Summers, E. M., Lograsso, T. A. & Wun-Fogle, M. Magnetostriction of binary and ternary Fe-Ga alloys. J. Mater. Sci. 42, 9582–9594 (2007).

Jayaraman, T. V., Corson, R. P. & Guruswamy, S. Ordering, magnetostriction, and elastic properties in Fe-27.5 at. % Ga alloy single crystals. J. Appl. Phys. 102, 053905 (2007).

Jin, C., Liu, J. H. & Jiang, C. B. Magnetic domain characterization of high magnetic field treated FeGa single crystal. Mater. Res. Innov. 18, S4-597–S4-600 (2014).

Li, X. L., Bao, X. Q., Yu, X. & Gao, X. X. Magnetostriction enhancement of Fe73Ga27 alloy by magnetic field annealing. Scr. Mater. 147, 64–68 (2018).

Ikeda, O., Kainuma, R., Ohnuma, I., Fukamichi, K. & Ishida, K. Phase equilibria and stability of ordered b.c.c. phases in the Fe-rich portion of the Fe-Ga system. J. Alloy. Compd. 347, 198–205 (2002).

Srisukhumbowornchai, N. & Guruswamy, S. Influence of ordering on the magnetostriction of Fe-27.5 at. % Ga alloys. J. Appl. Phys. 92, 5371–5379 (2002).

Gou, J. M. et al. Tailoring magnetostriction sign of ferromagnetic composite by increasing magnetic field strength. Appl. Phys. Lett. 109, 082404 (2016).

Ma, T. Y. et al. Highly thermal-stable ferromagnetism by a natural composite. Nat. Comm. 8, 13937 (2017).

Palacheva, V. V. et al. Phase transitions as a tool for tailoring magnetostriction in intrinsic Fe-Ga composites. Acta Mater. 130, 229–239 (2017).

Fitchorov, T. I. et al. Thermally driven large magnetoresistance and magnetostriction in multifunctional magnetic FeGa-Tb alloys. Acta Mater. 73, 19–26 (2014).

Meng, C. Z., Wang, H., Wu, Y. Y., Liu, J. H. & Jiang, C. B. Investigating enhanced mechanical properties in dual-phase Fe-Ga-Tb alloys. Sci. Rep. 6, 34258 (2016).

Dai, L., Cullen, J., Wuttig, M., Lograsso, T. & Quandt, E. Magnetism, elasticity, and magnetostriction of FeCoGa alloys. J. Appl. Phys. 93, 8627–8629 (2003).

Xu, S. F. et al. Magnetostriction and electrical resistivity of Mn doped Fe81Ga19 alloys. J. Phys. D: Appl. Phys. 41, 015002 (2008).

Ren, S. et al. Low-field-triggered large magnetostriction in iron-palladium strain glass alloys. Phys. Rev. Lett. 119, 125701 (2017).

Liu, J. J. et al. Magnetic transitions and magnetostrictive properties of TbxDy1-x(Fe0.8Co0.2)2 (0.20 ≤ x ≤ 0.40). Phys. Rev. B 75, 064429 (2007).

Xing, Q., Du, Y., McQueeney, R. J. & Lograsso, T. A. Structural investigations of Fe–Ga alloys: phase relations and magnetostrictive behavior. Acta Mater. 56, 4536–4546 (2008).

Lograsso, T. A., Ross, A. R., Schlagel, D. L., Clark, A. E. & Wun-Fogle, M. Structural transformations in quenched Fe-Ga alloys. J. Alloy. Compd. 350, 95–101 (2003).

He, Y. K. et al. Giant heterogeneous magnetostriction in Fe-Ga alloys: Effect of trace element doping. Acta Mater. 109, 177–186 (2016).

He, Y. K. et al. Interaction of trace rare-earth dopants and nanoheterogeneities induces giant magnetostriction in Fe-Ga alloys. Adv. Funct. Mater. 28, 1800858 (2018).

Jin, T. Y., Wang, H., Golovin, I. S. & Jiang, C. B. Microstructure investigation on magnetostrictive Fe100-xGax and (Fe100-xGax)99.8Tb0.2 alloys for 19≤ × ≤29. Intermetallics 115, 106628 (2019).

Lograsso, T. A. & Summers, E. M. Detection and quantification of D03 chemical order in Fe-Ga alloys using high resolution X-ray diffraction. Mater. Sci. Eng. A 416, 240–245 (2006).

Jen, S. U., Cheng, W. C. & Chiang, F. L. Structural, magneto-mechanical, and damping properties of slowly-cooled polycrystalline Fe81Ga19 alloy. J. Alloy. Compd. 651, 544–550 (2015).

Rahman, N., Li, M. X., Ma, T. Y. & Yan, M. Microstructural origin of the magnetostriction deterioration in slowly-cooled Fe81Ga19. J. Alloy. Compd. 786, 300–305 (2019).

Xing, Q. & Lograsso, T. A. Effect of cooling rate on magnetoelasticity and short-range order in Fe-Ga alloys. Scr. Mater. 65, 359–362 (2011).

Mohamed, A. K. et al. First- and second-order phase transitions in Fe-(17-19)at.%Ga alloys. Mater. Lett. 279, 128508 (2020).

Golovin, I. S., Balagurov, A. M., Bobrikov, I. A., Sumnikov, S. V. & Mohamed, A. K. Cooling rate as a tool of tailoring structure of Fe-(9-33%)Ga alloys. Intermetallics 114, 106610 (2019).

Balagurov, A. M., Samoylova, N. Y., Bobrikov, I. A., Sumnikov, S. V. & Golovin, I. S. The first- and second-order isothermal phase transitions in Fe3Ga-type compounds. Acta Cryst. B75, 1024–1033 (2019).

Khachaturyan, A. G. & Viehland, D. Structurally heterogeneous model of extrinsic magnetostriction for Fe-Ga and similar magnetic alloys: part I. decomposition and confined displacive transformation. Metall. Mater. Trans. A 38, 2308–2316 (2007).

Gou, J. M., Yang, T. Z., Qiao, R. H., Liu, Y. & Ma, T. Y. Format the ion mechanism of the tetragonal nanoprecipitates in Fe-Ga alloys that dominate material’s large magnetostriction. Scr. Mater. 185, 129–133 (2020).

Wagner, W., Wiedenmann, A., Petry, W., Geibel, A. & Gleiter, H. Magnetic microstructure of nanostructured Fe, studied by small angle neutron scattering. J. Mater. Res. 6, 2305–2311 (1991).

Laver, M. et al. Magnetostriction and magnetic heterogeneities in iron-gallium. Phys. Rev. Lett. 105, 027202 (2010).

Mudivarthi, C. Magnetic and structural characterization of Fe-Ga using Kerr microscopy and neutron scattering. (University of Maryland, College Park. PhD thesis, 2010).

Bischof, M. et al. The influence of spin-misalignment scattering on the SANS data evaluation of martensitic age-hardening steels. Acta Mater. 55, 2637–2646 (2007).

Michels, A. & Weissmüller, J. Magnetic-field-dependent small angle neutron scattering on random anisotropy ferromagnets. Rep. Prog. Phys. 71, 066501 (2008).

Zhang, Y. N., Wang, H. & Wu, R. Q. First-principles determination of the rhombohedral magnetostriction of Fe100-xAlx and Fe00-xGax alloys. Phys. Rev. B 86, 224410 (2012).

Zhang, Y. N. & Wu, R. Q. Mechanism of large magnetostriction of Galfenol. IEEE Trans. Magn. 47, 4044–4049 (2011).

Wang, H. et al. Understanding strong magnetostriction in Fe100-xGax alloys. Sci. Rep. 3, 3521 (2013).

Ruffoni, M. P. et al. Direct measurement of intrinsic atomic scale magnetostriction. Phys. Rev. Lett. 101, 147202 (2008).

Bhattacharyya, S. et al. Nanodispersed D03-phase nanostructures observed in magnetostrictive Fe-19% Ga Galfenol alloys. Phys. Rev. B 77, 104107 (2008).

Rahman, N., Gou, J. M., Liu, X. L., Ma, T. Y. & Yan, M. Enhanced magnetostriction of Fe81Ga19 by approaching an instable phase boundary. Scr. Mater. 146, 200–203 (2018).

Khachaturyan, A. G. & Viehland, D. Structurally heterogeneous model of extrinsic magnetostriction for Fe-Ga and similar magnetic alloys: part II. giant magnetostriction and elastic softening. Metall. Mater. Trans. A 38, 2317–2328 (2007).

Ren, X. B. Strain glass and ferroic glass-Unusual properties from glassy nano-domains. Phys. Status Solidi B 251, 1982–1992 (2014).

Seiner, H., Kopecky, V., Landa, M. & Heczko, O. Elasticity and magnetism of Ni2MnGa premartensitic tweed. Phys. Status Solidi B 251, 2097–2103 (2014).

Lloveras, P., Castán, T., Porta, M., Planes, A. & Saxena, A. Influence of elastic anisotropy on structural nanoscale textures. Phys. Rev. Lett. 100, 165707 (2008).

Kronmüller, P. Theory of nucleation fields in inhomogeneous ferromagnets. Phys. Status Solid. B 144, 385–396 (1987).

Han, Y. J. et al. Tailoring the heterogeneous magnetostriction in Fe-Co alloys. J. Alloy. Compd. 699, 200–209 (2017).

Zhao, Y. L. et al. Magnetostriction and structure characterizations of Co70Fe30 alloy prepared by directional solidification. J. Magn. Magn. Mater. 451, 587–593 (2018).

Lisfi, A., Ren, T., Khachatuyan, A. & Wuttig, M. Nano-magnetism of magnetostriction in Fe35Co65. Appl. Phys. Lett. 104, 092401 (2014).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51871174, 52071256, and 51831006), the Young Talent Support Plans of XJTU and Shaanxi Province, the Fundamental Research Funds for Central Universities, the fund of the State Key Laboratory of Solidification Processing in NPU (Grant No. SKLSP202003), the Key Scientific and Technological Innovation Team of Shaanxi Province (2020TD-001), and the State Key Laboratory for Mechanical Behavior of Materials.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gou, J., Ma, T., Liu, X. et al. Large and sensitive magnetostriction in ferromagnetic composites with nanodispersive precipitates. NPG Asia Mater 13, 6 (2021). https://doi.org/10.1038/s41427-020-00276-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41427-020-00276-7

This article is cited by

-

Local Displacive Phase Transformation in Large-Magnetostriction Alloy Fe81Ga19

Shape Memory and Superelasticity (2023)

-

Tailoring coercive field in rare earth giant magnetostrictive materials by α-Fe precipitation

Rare Metals (2023)

-

Centrifugal Casting of Fe82Ga18 Alloy as a Tool of Mechanical Properties Improvement

Metallurgical and Materials Transactions A (2021)