Abstract

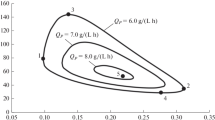

A computational scheme has been presented for estimating the technological characteristics of the continuous fermentation of lactic acid at a given concentration of the component that produces the main substrate. The computational scheme includes a preliminary analysis, the principal analysis, and a numerical example of the implementation of calculation. In the preliminary analysis, relationships for estimating the boundary characteristics have been given that form the region of values for these characteristics that, in fact, ensure a given concentration of the component producing the main substrate (M0, g/L). The coordinates of the point of the maximum productivity and singular points have been determined. The positions of these coordinates have been illustrated using a portrait of the dependence of M0 on the dilution rate D for a productivity of QP = 6 g/(L h). This portrait also shows the boundaries of sections I, II, and III, for which computational relationships have been constructed. The scheme of the construction of computational relationships has been presented separately for each of the sections. The boundaries of sections are determined by relationships (22)–(24). Sets have been constructed at a given value of M0 for the coordinates of singular points, the extremum point QP, and each of the sections: Set1 for section I; Set1* and Set2* for section II; and Set1**, Set2**, and Set3** for section III. Theoretical relationships have been used for a numerical estimation of the characteristics of sets. It has been shown that the range of the assignment of M0 is the widest for section I, whereas the range of values for the dilution rate D is the greatest for section III. Numerical estimates in a comparative variant for sets in sections II and III have shown that the final concentrations of components under the same initial conditions differ in the values of M0 and S. This makes it possible to evaluate the further processing of synthesis products (the recovery of lactic acid, the recycling and use of unconverted components, and the recovery of a by-product).

Similar content being viewed by others

REFERENCES

Hofvendahl, K. and Hahn-Hägerdala, B., Factors affecting the fermentative lactic acid production from renewable resources, Enzyme Microb. Technol., 2000, vol. 26, pp. 87–107. https://doi.org/10.1016/S0141-0229(99)00155-6

Gonzalez, K., Tebbani, S., Lopes, F., Thorigné, A., Givry, S., Dumur, D., and Pareau, D., Modeling the continuous lactic acid production process from wheat flour, Appl. Microbiol. Biotechnol., 2016, vol. 100, no. 1, pp. 147–159. https://doi.org/10.1007/s00253-015-6949-7

Åkerberg, C., Hofvendahl, K., Zacchi, G., and Hahn-Hägerdal, B., Modelling the influence of pH, temperature, glucose and lactic acid concentrations on the kinetics of lactic acid production by Lactococcus lactis ssp. lactis ATCC 19435 in whole-wheat flour, Appl. Microbiol. Biotechnol., 1998, vol. 49, no. 6, pp. 682–690. https://doi.org/10.1007/s002530051232

Gordeeva, Yu.L., Borodkin, A.G., and Gordeeva, E.L., Estimating the technological characteristics of lactic acid production by continuous fermentation: Optimal conditions, Theor. Found. Chem. Eng., 2020, vol. 54, no. 1, pp. 216–221. https://doi.org/10.1134/S004057952001008X

Funding

The study was funded by the Mendeleev University of Chemical Technology of Russia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Uteshinsky

APPENDIX

APPENDIX

Rights and permissions

About this article

Cite this article

Gordeeva, Y.L., Ravichev, L.V. & Gordeeva, E.L. Estimating the Multiplicity of the Steady States of a Fermentation Process for Lactic Acid Production at a Given Concentration of the Component Producing the Main Substrate. Theor Found Chem Eng 54, 1256–1266 (2020). https://doi.org/10.1134/S0040579520060160

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579520060160