Abstract

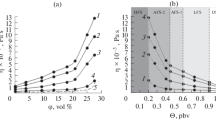

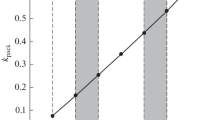

Questions of the influence of the particle size of solid fillers on the packing density and the maximum filler fraction (φm) in dispersion-filled polymer composite materials (DFPCMs) are studied. The dependence of the parameter φm from the diameter of solid particles of fillers is given. It is shown that, for large particles (over 50 μm), φm in DFPCMs can reach ~0.64 vol/vol and, for nanoparticles (1–100 nm), it can reach no more than ~0.255 vol/vol. For deformable-under-pressure and gaseous particles, as well as for dense compositions of fillers, the value of parameter φm in DFPCMs can reach ~0.90–0.94 vol/vol. The relationship between the size of particles and their packing and the generalized parameter of the dispersed structure Θ has been established, which makes it possible to classify the type of materials under consideration with different particle sizes according to the structural principle and establish their type of structural organization (dilute, low-filled, medium-filled, highly filled, and ultra-high-filled systems), which determines the properties of composites. An algorithm is proposed for calculating the content of filler and compositions of DFPCMs with different particle sizes, natures, and deformability of particles for the design of various types of composite structures and technological and operational properties.

Similar content being viewed by others

REFERENCES

Napolniteli dlya polimernykh kompozitsionnykh materialov: spravochnoe posobie (Fillers for Polymeric Composite Materials: A Handbook), Kats, G.S. and Milevski, D.V., Eds., Moscow: Khimiya, 1981.

Simonov-Emel’yanov, I.D., Lattice and structure parameters for dispersion-filled polymeric composite materials with a regulated complex of properties, Konstr. Kompoz. Mater., 2019, no. 3, p. 37.

Simonov-Emel’yanov, I.D., Shembel’, N.L., Prokopov, N.I., Ushakova, O.B., Gerval’d, A.Yu., Surikov, P.V., Markov, A.V., and Pashkin, I.I., Metody opredeleniya tekhnologicheskikh svoistv napolnitelei i polimernykh materialov (Methods for Determining the Technological Properties of Fillers and Polymeric Materials), Moscow: Mosk. Gos. Univ. Tonk. Khim. Tekhnol. im. M.V. Lomonosova, 2014.

Antsiferov, V.N. and Perel’man, V.E., Mekhanika protsessov pressovaniya porshkovykh i kompozitsionnykh materialov (Mechanics of the Pressing of Powdered and Composite Materials), Moscow: Graal’, 2001.

Mechanics of Cellular Plastics, Hilyard, N.C., Ed., New York: Macmillan, 1982.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Simonov-Emelyanov, I.D., Kharlamova, K.I. Filler Particle Size and Packaging and Compositions of Filled Polymer Composites with Different Types of Structures and Properties. Theor Found Chem Eng 54, 1290–1296 (2020). https://doi.org/10.1134/S0040579520060214

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579520060214