Abstract

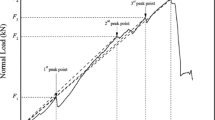

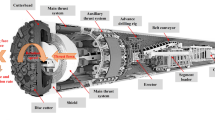

Rock mass boreability plays a key role in the performance of tunnel boring machines (TBMs). The angle and orientation of the plane of joint are two factors which affect the boreability of the jointed rock masses. This paper is aimed at describing the combined effects of joint orientation and spacing on the boreability and presenting a new model and classification system to predict the boreability of the jointed rock masses, focusing on field studies. In this regard, a database of three water conveyance projects including the Queens Tunnel in USA, Kerman Tunnel in Iran, and Maroshi-Ruparel Tunnel in India has been employed. A total fracturing factor (presented by Bruland) has been applied as well. The results showed that the increase in the total fracturing factor will result in higher boreability. A model was developed for predicting the boreability of the jointed rock mass based on the total fracturing factor, and the convergence coefficient of this model was 0.7. The volumetric joint count classification system was also developed to analyze the relationship between the total fracturing factor and the volumetric joint count. In order to predict the boreability of the jointed rock mass in the Zagros Tunnel in Iran, the boreability was classified in three categories. The result showed a good agreement between the predicted and actual boreability of the jointed rock mass.

Similar content being viewed by others

References

Aeberli U, Wanner WJ (1978) On the influence of discontinuities at the application of tunneling machines. In: Proceedings of the 3rd International Congress IAEG, Madrid, pp 7–14

Azarafza M, Akgun Ebrahim H, Kaljahi A (2018) Stochastic geometry model of rock mass fracture network in tunnels. Q J Eng Geol Hydrogeol 51(3):379–386. https://doi.org/10.1144/qjegh2017-136

Barton N (2000) TBM Tunnelling in Jointed and Fault Rock. Balkema, Rotterdam

Bejari H, Khademi J (2013) Simultaneous effects of joint spacing and orientation on TBM cutting efficiency in jointed rock masses. Rock Mech Rock Eng 46:897–907. https://doi.org/10.1007/s00603-012-0314-2

Bieniawski von Preinl ZT, Celada Tamames B, Galera Fernandez JM, Alvarez Hernandez M (2006) Rock masse excavability indicator: new way to selecting the optimum tunnel construction method. Tunn Undergr Space Technol 21(3–4):237

Bruland A (2000) Hard rock tunnel boring: vol 1–10 PhD thesis. Norwegian University of Science and Technology (NTNU), Trondheim

Büchi E (1984) Einfluss geologischer parameter auf die vortriebsleistung einer tunnelbohrmaschine. PhD Thesis. University of Bern

Cui Q, Shen S, Yin Z (2016) Protection of neighbour buildings due to construction of shield tunnel in mixed ground with sand over weathered granite. Environ Earth Sci 75:458. https://doi.org/10.1007/s12665-016-5300-7

Delisio A, Zhao J, Einstein HH (2013) Analysis and prediction of TBM performance in blocky rock conditions at the Lötschberg Base Tunnel. Tunn Undergr Space Technol 33:131–142

Farrokh E, Rostami J (2009) Effect of adverse geological condition on TBM operation in Ghomroud tunnel conveyance project. Tunnel Undergr Space Technol 24(4):436–446. https://doi.org/10.1016/j.tust.2008.12.006

Gehring K (1997) Classification of drillability, cuttability, borability and abrasivity in tunnelling. Felsbau Magazin 15(3):183–189

Gong QM, Zhao J (2009) Development of a rock mass characteristics model for TBM penetration rate prediction. Int J Rock Mech Min Sci 46(1):8–18. https://doi.org/10.1016/j.ijrmms.2008.03.003

Gong QM, Zhao J, Jiao YY (2005) Numerical modelling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunnel Undergr Space Technol 20(2):183–191. https://doi.org/10.1016/j.tust.2004.08.006

Gong QM, Jiao YY, Zhao J (2006a) Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunnel Undergr Space Technol 21(1):46–55. https://doi.org/10.1016/j.tust.2005.06.004

Gong QM, Zhao J, Hefny AM (2006b) Numerical simulation of rock fragmentation process induced by two TBM cutters and cutter spacing optimization. Tunn Undergr Space Technol 21:263

Hamilton W, Dollinger G (1979) Optimizing tunnel boring machine and cutter design for greater boreability. RETC Proc Atlanta 1:280–296

Hassanpour J, Rostami J, Khamehchiyan M, Bruland A, Tavakoli HR (2010) TBM performance analysis in pyroclastic rocks: a case history of Karaj Water Conveyance. Tunnel Rock Mech Rock Eng 43(4):427–445. https://doi.org/10.1007/s00603-009-0060-2

Hassanpour J, Rostami J, Zhao J (2011) A new hard rock TBM performance prediction model for project planning. Tunn Undergr Space Technol 26:595–603. https://doi.org/10.1016/j.tust.2011.04.004

Huang H, Detournay E (2013) Discrete element modeling of toolrock interaction II:rock indentation. Int J Numer Anal Methods Geomech 37(13):1913–1929

Huang H, Lecampion B, Detournay E (2013) Discrete element modeling of tool-rock interaction I: Rock indentation. Int J Numer Anal Methods Geomech 37(13):1913–1929

Khademi Hamidi J, Shahriar K, Rezai B, Rostami J (2010) Performance prediction of hard rock TBM using Rock Mass Rating (RMR) system. Tunn Undergr Space Technol 25:333–345. https://doi.org/10.1016/j.tust.2010.01.008

Lindqvist PA, Lai HH (1983) Behaviour of the crushed zone in rock indentation. Rock Mech Rock Eng 16:199–207. https://doi.org/10.1007/bf01033280

Ma HS, Ji HG (2011) Experimental study of the effect of joint orientation on fragmentation modes and penetration rate under TBM disc cutters. Chin J Rock Mech Eng 30:155–163

Ma HS, Yin LJ, Gong QM, Wang J (2013) Experimental study on the effect of joint spacing on fragmentation modes and penetration rate under TBM disc cutters. In Applied Mechanics and Materials. Trans Tech 353:890–894

Macias F (2016) Hard rock tunnel boring performance predictions and cutter life assessments. Thesis for the degree of Philosophiae Doctor, Norwegian University of Science and Technology

Maleki MR (2018) Rock joint rate (RJR); a new method for performance prediction of tunnel boring machines (TBMs) in hard rocks. Tunn Undergr Space Technol 73:261–286. https://doi.org/10.1016/j.tust.2017.12.022

Okubo S, Fukuim K, Chen W (2010) Size and shape of TBM debris estimated by the Nishimatsu's cutting resistance equation. Open Civil Eng 4:88–95. https://doi.org/10.2174/1874149501004010088

Palmström A (1982) The volumetric joint count - a useful and simple measure of the degree of rock mass jointing. Proceedings of 4th International Congress IAEG 5:221–228

Paltrinieri E (2015) Analysis of TBM tunnelling performance in faulted and highly fractured rocks. Doctor of Philosophy thesis, Ecole Polytechnique Federale DE LAUASANNE.

Ping C, Qibin L, Kaihui L, Dongya H (2017) Effects of joint angle and joint space on rock fragmentation efficiency by two TBM disc cutters. J Cent S Univ (Sci Technol). https://doi.org/10.11817/j.issn.1672-7207.2017.05.023

Poisel R, Tentschert E, Preh A, Osteemann V, Chwatal W, Zettler A (2010) The interaction of machine and rock mass analysed using TBM data and rock mass parameters. Geomechan Tunnel 3(5):510–519. https://doi.org/10.1002/geot.201000043

Ramezanzadeh A, Rostami J, Richard K (2005) Influence of rock mass properties on performance of hard rock TBMS. Rapid excavation and tunneling conference, Chapter 56.

Ramezanzadeh A, Rostami J, Tadic D (2008) Impact of rock mass characteristics on hard rock tunnel boring machine performance. 13th Australian Tunneling Conference, Melbourne, VIC, 4 - 7 May.

Salimi A, Rostami J (2016) Application of non-linear regression analysis and artificial intelligence algorithms for performance prediction of hard rock TBMs. Tunnel Undergr Space Technol:236–246. https://doi.org/10.1016/j.tust.2016.05.009

Sanio HP (1985) Prediction of the performance of disc cutters in anisotropic rock. Int J Rock Mech Min Sci Geomech Abstr 22(3):153–161. https://doi.org/10.1016/0148-9062(85)93229-2

Seungoong L, Sung H (2009) Numerical analysis on fragmentation mechanism by indentation of disc cutter in a rock specimen with a single joint. Tunn Undergr Space Technol 19(5):440–449

Sharifzadeh M, Iranzadeh A (2009) Three-dimensional numerical modelling of joint spacing and orientation effects on rock cutting process by a single TBM. Published in Canadian Institue of Mining, Metalllurgy and Petroleum Magazine, Vol 4, No 6. 0000-0002-8139-1079

Shen S, Wang Z, Cheng W (2017) Estimation of lateral displacement induced by jet grouting in clayey soils. Geotechnique, ICE 67:621–630. https://doi.org/10.1680/jgeot.16.p.159

Sungong C, Seungoong L (2015) Numerical study to estimate the cutting power on a disc cutter in jointed rock mass. KSCE J Civ Eng 1–2. https://doi.org/10.1007/s12205-015-2265-0

Tentschert E, Poisel R, Zettler A (2005) Gefügeeinfluss auf TBM-Vortriebe. Felsbau Magz 23(5):42–47

Thuro K, Plinninger RJ (2003) Hard rock tunnel boring, cutting, drilling and blasting: rock parameters for excavatability. Paper presented at the ISRM 2003

Türtscher M (2012)Analyse von Penetration und Vortriebsgeschwindigkeit bei maschinellen Vortrieben in Festgestein. – Dissertation Thesis, Leopold- Franzens-Universität Innsbruck, Innsbruck, pp 392

Wanner H, Aeberli U (1979) Tunnelling machine performance in jointed rock. In: Proceedings of 4th Congress of the InternationalSociety for Rock Mechanics, Montreux, pp 573–580

Wilfing L (2016) The influence of geotechnical parameters on penetration prediction in TBM tunneling in hard rock, PhD Thesis. Technical University of Munich, Munich

Yagiz S (2002) Dewelopment of rock fracture and brittleness indices to quantify the effects of rock mass features and toughnessn the CSM model basic penetration for hardrock tunnel machines. Thesis Doctor of Philosophy. Colorado School of Mine.

Yagiz S (2008) Utilizing rock mass properties for predicting TBM performance in hard rock condition. Tunnel Undergr Space Technol 23(3):326–399. https://doi.org/10.1016/j.tust.2007.04.011

Yin LJ, Gong QM, Zhao J (2014) Study on rock mass boreability by TBM penetration test under different in situ stress conditions. Tunn Undergr Space Technol 43:413–425

Zare Naghadehi M, Ramezanzadeh A (2016) Models for estimation of TBM performance in granitic and mica gneiss hard rocks in a hydropower tunnel. Bull Eng Geol Environ 76:1627–1641

Zhao T, Crosta GB, Utili S, De Blasio FV (2017) Investigation of rock fragmentation during rockfalls and rock avalanches via 3-D discrete element analyses. J Geophys Res Earth Surf 122:678–695

Zou F, Zhou C (2012) Experimental study of influence of joint space and jointed angle on rock fragmentation by TBM disc cutter. Rock Soil Mech 33(6):1640–1646

Zhou X, Jianping J, Zhan V, Song S, Cao C (2019) Identification of structural domains considering the combined effect of multiple joint characteristics. Q J Eng Geol Hydrogeol 52:375–385. https://doi.org/10.1144/qjegh2018-091

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Khosravi, M., Ramezanzadeh, A. & Zare, S. Effects of joint orientation and spacing on the boreability of jointed rock mass using tunnel boring machines. Arab J Geosci 14, 61 (2021). https://doi.org/10.1007/s12517-020-06428-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-06428-x