Abstract

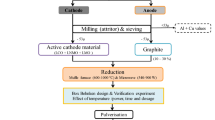

Ni-metal hydride (NiMH) batteries should be recycled, as they contain base metals (Ni, Co) and rare earth elements (La, Ce). In this study, thermal and microwave treatments are investigated as a pre-treatment method for decomposing electrode material (Ni(OH)2 and LaNi5). The kinetic analysis of thermal decomposition electrode material yields the activation energy of 41.3 kJ/mol. The maximum percentage of lanthanum nickel oxide phase and cerium oxide phase is obtained at 1000°C of thermal treatment and 15 min of microwave exposure. The formation of melted balls of Ni and its oxide (Ni ~ 72.8%) was observed in microwave exposure, and the tendency of ball formation decreased with increasing exposure time. The effect of microwave exposure and thermal treatment on the acid leaching (1 M HCl, at S/L-1:20, at 70°C for 2 h) was studied. The leaching results showed NiO and CeO2 phases in the leach residue of thermal and microwave treated products.

Similar content being viewed by others

References

P. Zhang, T. Yokoyama, O. Itabashi, Y. Wakui, T.M. Suzuki, and K. Inoue, Hydrometallurgy 50, 61 (1998).

P. Meshram, B.D. Pandey, and T.R. Mankhand, Waste Manag. 51, 196 (2016).

K. Binnemans, P.T. Jones, B. Blanpain, T. Van Gerven, Y. Yang, A. Walton, and M. Buchert, J. Clean. Prod. 51, 1 (2013).

L. Li, S. Xu, Z. Ju, and F. Wu, Hydrometallurgy 100, 41 (2009).

S. Maroufi, R.K. Nekouei, R. Hossain, M. Assefi, and V. Sahajwalla, ACS Sustain. Chem. Eng. 6, 11811 (2018).

K. Provazi, B.A. Campos, D.C.R. Espinosa, and J.A.S. Tenório, Waste Manag. 31, 59 (2011).

K. Young and J. Nei, Materials (Basel) 6, 4574 (2013).

V. Innocenzi, N.M. Ippolito, I. De Michelis, M. Prisciandaro, F. Medici, and F. Vegliò, J. Power Sources 362, 202 (2017).

United States Geological Survey (USGS), Mineral Commodity Summaries 2020 (2020).

P. Meshram, H. Somani, B.D. Pandey, T.R. Mankhand, and H. Deveci, J. Clean. Prod. 157, 322 (2017).

B. Ebin, J. Inorg. Organomet. Polym Mater. 28, 2554 (2018).

V. Agarwal, M.K. Khalid, A. Porvali, B.P. Wilson, and M. Lundström, Sustain. Mater. Technol. 22, e00121 (2019).

T. Müller and B. Friedrich, J. Power Sources 158, 1498 (2006).

S. Al-Thyabat, T. Nakamura, E. Shibata, and A. Iizuka, Miner. Eng. 45, 4 (2013).

A. Porvali, B.P. Wilson, and M. Lundström, Waste Manag. 71, 381 (2018).

K. Tang, A. Ciftja, A.M. Martinez, C. van der Eijk, Y. Bian, S. Guo, and W. Ding, Proceedings of the First International Symposium on Development of Rare Earths, Baotou, China 8 (2014).

P.R. Behera, R. Farzana, and V. Sahajwalla, J. Clean. Prod. 249, 119407 (2020).

R. Farzana, K. Hassan, W. Wang, and V. Sahajwalla, J. Environ. Manag. 234, 145 (2019).

E.H. Tanabe, D.F. Schlemmer, M.L. Aguiar, G.L. Dotto, and D.A. Bertuol, J. Environ. Manag. 171, 177 (2016).

B. Ebin, M. Petranikova, and C. Ekberg, J. Mater. Cycles Waste Manag. 20, 2018 (2018).

K. Korkmaz, M. Alemrajabi, Å. Rasmuson, and K. Forsberg, J. Sustain. Metall. 4, 313 (2018).

P. Zhang, T. Yokoyama, O. Itabashi, Y. Wakui, T.M. Suzuki, and K. Inoue, J. Power Sources 77, 116 (1999).

N. Tzanetakis and K. Scott, J. Chem. Technol. Biotechnol. 79, 919 (2004).

D.A. Bertuol, A.M. Bernardes, and J.A.S. Tenório, J. Power Sources 193, 914 (2009).

P. Meshram, B.D. Pandey, and T.R. Mankhand, Hydrometallurgy 158, 172 (2015).

L. Pietrelli, B. Bellomo, D. Fontana, and M.R. Montereali, Hydrometallurgy 66, 135 (2002).

S. Pindar and N. Dhawan, Sustain. Mater. Technol. 25, e00157 (2020).

Y. Huang, T. Zhang, Z. Dou, G. Lv, G. Han, and W. Peng, J. Rare Earths 37, 541 (2019).

Y. Huang, T. Zhang, J. Liu, Z. Dou, and J. Tian, J. Rare Earths 34, 529 (2016).

F. Maurel, B. Knosp, and M. Backhaus-Ricoult, J. Electrochem. Soc. 147, 78 (2000).

U. Kumar, V. Gaikwad, and V. Sahajwalla, J. Clean. Prod. 192, 244 (2018).

S. Pindar and N. Dhawan, J. Therm. Anal. Calorim. (2020). https://doi.org/10.1007/s10973-020-10139-6.

X. Yang, J. Zhang, and X. Fang, J. Hazard. Mater. 279, 384 (2014).

C.A. Pickles, Miner. Eng. 22, 1112 (2009).

E.R. Bobicki, C.A. Pickles, J. Forster, O. Marzoughi, and R. Hutcheon, Miner. Eng. 145, 106055 (2020).

J. Chaouki, S. Farag, M. Attia, and J. Doucet, Can. J. Chem. Eng. 98, 832 (2020).

L. Nie, J. Wang, and Q. Tan, Catal. Commun. 97, 1 (2017).

N. Wang, Q. Zhang, P. Zhao, M. Yao, W. Hu, and S. Komarneni, Ceram. Int. 43, 5687 (2017).

N. Shukla and N. Dhawan, Process Saf. Environ. 142, 238 (2020).

L. Tifouti, N. Habbache, and S. Djerad, Process Eng. J. 1, 59 (2017).

P. Fleming, R.A. Farrell, J.D. Holmes, and M.A. Morris, J. Am. Ceram. Soc. 93, 1187 (2010).

Acknowledgements

The authors would like to thank the Indian Institute of Technology, Roorkee, for providing Faculty Initiation Grant funds via FIG-100714, and Mr. Sanjay Pindar for calculation work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mir, S., Shukla, N. & Dhawan, N. Investigation of Microwave and Thermal Processing of Electrode Material of End-of-Life Ni-MH Battery. JOM 73, 951–961 (2021). https://doi.org/10.1007/s11837-020-04530-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04530-9