Abstract

Advanced gas turbine and internal combustion engine combustion chambers operate at highly elevated pressures and temperatures. Therefore, spray vaporization analysis cannot be limited to the atmospheric environment since evaporation strongly depends on ambient conditions. Presently, the effect of air pressure and temperature on droplet evaporation rate was investigated by using both a transient and a steady-state approach. A corresponding states model was derived for the steady-state evaporation rate for n-alkanes in the range of C2–C9 with an excellent fit quality and < 1% model uncertainty, considering the thermophysical data uncertainties. The model was tested for C1, C10, and C12 n-alkanes as well with low success. The ambient conditions were evaluated in terms of reduced pressures and temperatures, covering the range of 0.02–0.5 and 1.2–1.5, respectively. However, the applicability of the model was limited to reduced temperature of 1.3–1.5, as higher discrepancy was observed between the trends of the different n-alkanes at lower temperatures. Since the heat-up phase of practical sprays in combustion chambers is often short, the present model might significantly reduce the computational effort required for liquid evaporation calculations.

Similar content being viewed by others

1 Introduction

The dependence of the energy and transportation sectors on combustion systems is significant. The fossil fuel utilization has been rapidly increasing. Especially in the Asian and African countries, reaching a share of 85–90% in the last decades (Kibria et al. 2019). Also, aviation has no alternative in the short term (Chiaramonti 2019). As renewable liquid fuel utilization is increasing, catalytic synthesis of n-alkanes from clean synthesis gas is gaining more importance (Deneyer et al. 2015; Lødeng et al. 2018).

Methane is the most promising liquid-propellant in the space industry (Pérez-Roca et al. 2019). N-butane is popular in spark-ignition engines to improve mixture formation (Jung et al. 2017). Evaporation and combustion of n-hexane, n-heptane, and n-octane are often investigated since their thermophysical and chemical properties are well-known (Pal and Bakshi 2018; Wu et al. 2019; AlZahrani and Dincer 2017). N-dodecane is the best one-component surrogate of diesel oil (Savard et al. 2019; Borghesi et al. 2018). Furthermore, n-alkanes are present in all gasoline, kerosene, and diesel fuels (Deneyer et al. 2015). Ray and Raghavan (Ray and Raghavan 2020) determined a correlation for the time-averaged evaporation rate of several biodiesels. Similarly, the present paper aims to provide a method for calculating the steady-state evaporation rate, based on the law of corresponding states (LCS) for a range of n-alkanes to speed up the numerical droplet evaporation simulations.

The missing material properties in heat and mass transfer calculations are often patched by group contribution methods (GCM) and LCS (Poling et al. 2001). Normal boiling point and critical parameter estimation methods were proposed by Joback (Joback (1984); Joback and Reid 1987) and Constantinou et al. (Constantinou and Gani 1994; Constantinou et al. 1995). Chung et al. (1984,1988) and Svehla (1962) provided methods for vapor-phase thermal conductivity, while Elbro (Elbro et al. 1991) suggested a method for liquid-phase density. Nevertheless, droplet lifetime calculations may show an outstanding sensitivity on them, even though the estimation method provides sufficient prediction (Csemány and Józsa 2017). Consequently, vaporization calculation requires a continuum-based analysis.

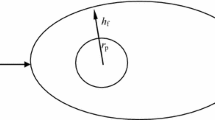

A milestone in droplet evaporation research was the introduction of the d2-law (Spalding 1953; Godsave 1953). In steady-state evaporation, the square of droplet diameter decreases linearly with time. Its slope is the steady-state evaporation rate that characterizes the intensity of the vaporization process (Lefebvre and McDonell 2017). State-of-the-art numerical methods are based on the aforementioned classical models (Fang et al. 2019; Ciottoli et al. 2020; Poulton et al. 2020). However, several unsolved problems have been still existing; therefore, improving, testing, and validating vaporization models are critical even today (Sazhin 2017; Pinheiro and Vedovoto 2019).

To better understand the physical phenomena of evaporation and validate vaporization models, single droplet measurement is usually performed. A rich experimental study was performed by Ghassemi et al. (Ghassemi et al. 2006) for millimeter-scale single droplets at varying ambient conditions. Nomura et al. (2017) investigated the pressure dependence of the droplet lifetime and the evaporation rate of n-hexadecane droplets in sub- and supercritical conditions in microgravity. Chauveau et al. (2011) analyzed the validity of the d2-law in case of n-decane droplet vaporization in microgravity and normal gravity conditions and then compared the droplet lifetime. Verwey and Birouk (2018) investigated the effect of natural convection on the steady-state evaporation rate of n-alkane droplets, while Nguyen et al. (2018) studied binary mixture droplets in a hot convective environment numerically with experimental validation. Hillenbrand and Brüggemann (Hillenbrand and Brüggemann 2020) applied non-intrusive optical measurement techniques to determine the vaporization characteristics of several alkane-ethanol mixtures and evaluated their mixture formation behavior.

The present paper aims to compare the evaporation characteristics of various n-alkanes in the range of C1–C12 for a wide range of ambient pressures and temperatures to draw general conclusions. Since the share of the heat-up period of the typical droplet sizes (5–20 μm (Lefebvre and McDonell 2017; Urbán et al. 2019)) in real combustion chambers is relatively small, steady-state evaporation phase of n-alkanes was emphasized. Beyond the direct application of the model for fossil fuels, if a mixture of these n-alkanes can substitute the distillation curve of any other liquid, then the method is still applicable for the estimation of vaporization.

2 Materials and Methods

The presently used droplet evaporation model is detailed in the literature (Lefebvre and McDonell 2017; Fuchs 1959; Sazhin 2014) and used in numerical codes (Ansys Fluent Theory Guide 2020). Therefore, this section overviews only the key equations of both transient and steady-state models. The equations below were solved in each time-step in the former case; thus the temporal variation of droplet diameter, thermophysical properties, droplet surface temperature, and evaporation properties could be obtained. Note that the droplet temperature in this analysis was uniform. The validation of the calculation method is presented in "Appendix 1" for the current parameter regime.

2.1 The Evaporation Models

Firstly, the core of the transient model is described. The mass fraction of fuel vapor on the droplet surface, assuming vapor–liquid equilibrium and ideal gas conditions, is given by Eq. (1):

where p∞ and pv,s are the ambient and vapor pressures, and M is the molar mass. Subscripts a and v refer to air and vapor, respectively. Equation (1) is valid only when the compressibility factor of the gas mixture is close to unity. Otherwise, a proper equation of state must be used to calculate phase equilibria on the droplet surface (Lopez-Echeverry et al. 2017). In the present calculations, Eq. (1) is used, and the justification of its application is presented in Sect. 3. The Spalding mass and heat transfer numbers are calculated by Eqs. (2) and (3) (Sazhin 2014; Abramzon and Sirignano 1989):

where Yv,∞ is the vapor mass fraction in the far-field. Presently, Yv,∞ = 0. cp,v and cp,g are the vapor and vapor-air mixture specific heat capacities, respectively. Le is the Lewis number, which is defined by Eq. (4):

where kg and ρg are the thermal conductivity and density of vapor-air mixture respectively, and Dv,a is the binary diffusion coefficient of vapor and air, estimated by the method of Fuller (Fuller et al. 1966,1969):

where Tref is the reference temperature, Mv,a is the average molar mass of the mixture substances, Σv is the sum of atomic and structural diffusion volume increments of the corresponding molecules. For calculating heat transfer, the Nusselt number of the droplet is:

where Nu0 is the Nusselt number for a non-evaporating sphere. There are several correlations exist for Nu0 calculation of both stagnant and moving droplets, accounting for natural and forced convection, respectively (Sazhin 2014; Springer 2010). Such correlations are shown by Eqs. (7) and (10):

where Pr is the Prandtl number, RaT is the Rayleigh number of a stagnant sphere for heat transfer, Gr is the Grashof number, g is the gravitational acceleration, β and μg are the thermal expansion coefficient and dynamic viscosity of the vapor-air mixture, respectively, Ts and T∞ are the droplet surface and ambient temperatures, respectively, d is the instantaneous droplet diameter, and Re is the Reynolds number of the moving spherical droplet. Equation (10) is the Ranz-Marshall Correlation, used extensively in spray simulations. Nusselt number is the ratio of convective to conductive heat transfer at the droplet surface.

Sherwood number is the ratio of convective mass transfer rate to diffusion rate. As a result of the analogous form of the fundamental equations in heat and mass transfer, Nusselt number correlations could be used for Sherwood number calculation by replacing Pr and RaT with the Schmidt number, Sc, and the Rayleigh number for mass transfer, RaM, respectively (Bergman et al. 2017):

Presently, Eq. (7) and (11) were used for calculations, as stagnant droplets are considered in order to eliminate the effect of forced convection on evaporation rate. It is important to note that if Gr → 0 or Re → 0, the effect of natural convection for stagnant or forced convection of moving droplets is negligible, hence Nu0 → 2 and Sh → 2. The enhanced convective transfer rate caused by droplet motion relative to the ambient gas is considered by Abramzon and Sirignano by introducing correction factors to Nusselt and Sherwood numbers (Abramzon and Sirignano 1989). However, these corrections in modelling are indistinguishable in the majority of practical applications (Sazhin 2014). The mass flow rate of evaporation, including the effect of Stefan flow is given by Eq. (14):

where the overdot notes the time derivative. Hence, the heat balance of the droplet is:

where md is the mass of the droplet, cp,l is the liquid-phase specific heat capacity, hd is the droplet heat transfer coefficient, calculated from Nu. L is the latent heat of vaporization, calculated by the Watson equation (Poling et al. 2001). The reference temperature, Tref, and mass fraction of the vapor, Yv,ref, is generally defined by the film theory (Lefebvre and McDonell 2017; Sazhin 2014), as shown by Eqs. (16) and (17):

The gas-phase and mixture properties are calculated for these reference quantities according to the appropriate mixing rules considering fuel vapor and air (Lefebvre and McDonell 2017):

where kv, μv, and ρv are the thermal conductivity, dynamic viscosity, and density of vapor, respectively. cp,a, ka, μa, and ρa are the specific heat capacity, thermal conductivity, dynamic viscosity, and density of air, respectively. Note that Eqs. (18)–(21) are limited to ideal mixture conditions when Dalton’s law and Amagat’s law are valid. It is also assumed that the compressibility factor is nearly unity, and the conditions are far from critical. Otherwise, a proper equation of state (Lopez-Echeverry et al. 2017) with parameters averaged from the pure components or estimation methods with corrections for high pressure (Poling et al. 2001) should be applied to determine the properties of the gaseous medium. The justification of the application of Eqs. (18)–(21) is presented in Sect. 3. Liquid-phase properties are calculated for Ts.

After a transient heat-up period, the droplet reaches steady-state evaporation, therefore Ts remains constant, and the temporal d2-profile shows a linear decrease according to the d2-law, as shown by Fig. 1. The steady-state evaporation rate, λst, is obtained by fitting a line to the 0.15 ≤ (d/d0)2 ≤ 0.5 data points, where d0 is the initial droplet diameter. The slope is the λst, also applied for single droplet evaporation measurements (Nomura et al. 2017). Liquid preheating shortens the heat-up period, making λst suitable to droplet lifetime approximation.

If the temporal evolution of droplet lifetime is out of interest, and the main objective is only determining the steady-state evaporation rate, e.g. for generating a lookup table for numerical analysis, another method can be applied, as well. The other method for obtaining λst, is the following. The Spalding heat transfer number can be calculated by Eq. (22):

where \({\dot{Q}}_{d}\) is the heat rate spent on raising the temperature of the droplet. In steady-state, it becomes zero, therefore the Spalding heat transfer number is calculated by Eq. (23):

defining the ratio of specific heat available for droplet evaporation to the latent heat of vaporization. As Ts is constant in the steady-state evaporation phase, evaporation can be calculated by solving Eqs. (2), (3), and (23), and obtaining the steady-state droplet surface temperature, Ts,st, iteratively. Once the steady-state surface temperature is determined, all the other properties can be calculated. Even though the method has limitations, it gives a reasonably good estimation for practical applications (Lefebvre and McDonell 2017). According to the d2-law, the temporal variation of the squared droplet diameter is linear, and the slope is the steady-state evaporation rate, according to Eq. (24):

Considering the instantaneous mass of the fuel droplet and taking its temporal derivative, the mass flow rate can be obtained, equal to the mass flow rate of vapor at the droplet surface, using Eq. (14). Finally, the steady-state evaporation rate can be written as:

where ρl is the droplet density. If Sh → 2, Eq. (25) can be simplified into:

Equation (26) ignores the effect of convection on droplet evaporation and shows that the steady-state evaporation rate depends only on the fuel material properties. However, heat and mass transfer, hence, the evaporation rate depend on Nu and Sh via Gr in the transient model, as shown by Eqs. (7)–(9) and Eqs. (11)–(12). This contradiction will be resolved in Sect. 3.

2.2 Properties of the Investigated n-alkanes

The dependence of λst on pressure and temperature was evaluated for eleven different n-alkanes, widely used in combustion systems. Also, they can be used as surrogate components of real mixtures. The pressure- and temperature-dependent material properties along with critical and boiling points are obtained from the National Institute of Standards and Technology (NIST) database (Lemmon et al. 2019). The mentioned material properties are thermal conductivity and dynamic viscosity of fuel vapor, specific heat capacity and density of liquid-phase and vapor-phase, vapor pressure, and latent heat of vaporization. The binary diffusion coefficient of vapor and air was calculated by using the method of Fuller (Fuller et al. 1966,1969). Table 1 summarizes the critical parameters, boiling temperature at atmospheric pressure, and molar masses of the investigated n-alkanes. Undecane is missing due to the lack of data in the NIST database.

In order to get into non-dimensional space and evaluate the characteristics of different fluids in general, the temperature and pressure were defined as reduced values, i.e., the ratio of the ambient to critical values:

The general concept of using reduced values comes from the law of corresponding states (LCS), where dimensionless properties of different substances follow universal variations of dimensionless state variables, thus functions related to reduced values are similar for all substances (Poling et al. 2001). According to the limits of the investigation, the pressure range was 0.02 ≤ pr ≤ 0.5, and the temperature range was 1.2 ≤ Tr ≤ 1.5, which are typical in practical combustion systems. Nonane was an exception since no data was available for Tr > 1.3. Note that applying the same reduced ambient conditions for the different n-alkanes results in different absolute ambient conditions as the critical parameters are unique for each substance.

3 Results and Discussions

Equation (26) in the steady-state model does not consider the effect of droplet diameter on the evaporation rate, therefore λst is independent of d. However, Nu and Sh explicitly depend on d via Gr for stagnant, and via Re for moving droplets. Consequently, λst has an indirect droplet size dependence. Figure 2a shows the deviation in λst of the transient model from the value calculated by Eq. (26) of the steady-state model. The temporal variation of Sh during the droplet lifetime for different initial droplet diameters is shown in Fig. 2b. td215% is the time elapsed until d2 reduces to 15% of d20. For stagnant droplets, Gr → 0, if d → 0, therefore Nu0 → 2 and Sh → 2 according to Eqs. (7) and (11), respectively. Thus, λst is practically independent of the diameter of small droplets, hence the difference between the transient and steady-state models can be neglected, λst is only the function of the thermophysical properties of the substance.

In Fig. 2a, the deviation is about 1% for a droplet with d0 = 5 μm, which is representative of modern atomizers in combustion systems (Urbán et al. 2019,2017), requested indirectly by the pollutant emission standards (Directive (EU) 2015). Sh reaches a steady-state value for small droplets, and the influence of droplet diameter decreases, as shown by Fig. 2b. Therefore, the steady-state model can be used for spray calculations for tiny droplets. However, the theoretical value of λst can be corrected by Nu or Sh to consider the effect of natural or forced convection (Lefebvre and McDonell 2017).

The deviation between the two models can be neglected for fine droplets, hence the transient model converges to the steady-state model at various conditions, as shown by Fig. 3. Figure 4 presents the decreasing Lewis number during the heat-up period as the initial evaporating mass is small. However, it remains above unity for steady-state evaporation, therefore, the Le = 1 assumption (Lefebvre and McDonell 2017) may lead to significant bias.

The calculated steady-state properties influencing evaporation are discussed next for different reduced pressure and temperature conditions. All the trends correspond to steady-state, which characterizes vaporization at a given condition. Properties of n-butane and n-octane are discussed together to show the effect of molar mass and carbon chain length. Note that Ts is increasing with both pressure and temperature, as shown by Fig. 3, leading to increased vapor-air film temperature around the droplet. For all the investigated vapor-air mixtures, the compressibility factor was between 0.95 and 1. The lower values correspond to high pressure and low temperature. Consequently, the ideal gas assumption in Eq. (1) and the ideal mixture model in Eqs. (18)–(21) are appropriate for the present work.

Figure 5 shows that Le notably exceeds unity at low pressure and temperature, which is relevant for steady-operating combustion systems, such as boilers, furnaces, and gas turbines. cp,v/cp,g, divided by Le in the exponent of BT in Eq. (3), is shown by Fig. 6. Elevated pressure increases cp,v, which is more significant at lower temperatures, near the critical point. The decrease of Le and increase of specific heat capacity ratio enhance each other at higher pressure, increasing the exponent of Eq. (3), as shown by Fig. 7. Therefore, the unity exponent of Eq. (3) may lead to significant bias in droplet evaporation calculations.

The exponent of Eq. (3) for a n-butane and b n-octane

Figure 8 shows that BT increases with both pressure and temperature, while Fig. 9 shows that the specific heat available for droplet vaporization has a minimum at low Tr and monotonously decreasing at high Tr with pr. The difference between T∞ and Ts,st decreases with increasing pr, since the steady-state droplet surface temperature is higher at higher pressure. On the other hand, increasing Tr, thus T∞ increases the difference. cp,v increases with pr, especially at lower temperatures, resulting in a small increase in the specific heat at low temperatures. However, at high temperatures, the decrease in the temperature difference dominates the trends. L decreases with both pr and Tr, resulting in an overall increase in BT with pressure.

The different terms of Eq. (26) are evaluated next in order to characterize the trends of steady-state evaporation rate. The binary diffusion coefficient of vapor and air decreases with pressure and increases with temperature, as shown by Eq. (5). However, increasing pressure also increases the temperature of the gaseous mixture around the droplet. The density of the vapor-air mixture increases with pressure and decreases with temperature. Increasing pressure or temperature decreases droplet density as the temperature of the droplet increases. Higher pressure enhances this effect, thus the decrease of ρl with temperature is more significant at higher pressures.

Figure 10 shows the term Dv,a∙ρg/ρl from Eq. (26) for C2–C9 n-alkanes, where the trends are matching for the different molecules, except for ethane. However, ethane has a slightly different molecular structure as it has only two CH3 groups without a CH2 group. Nevertheless, this difference shrinks as temperature increases. This behavior of ethane was highlighted by Ewender and Welle (Ewender and Welle 2019). They experimentally investigated the permeation and diffusion characteristics of n-alkanes from methane up to n-dodecane through a polyethylene naphthalate film since their focus was on the barrier properties of polymers. The diffusion coefficients of methane and ethane were reported slightly outlying, referring to the different molecular structures (see Fig. 4 in ref. (Ewender and Welle 2019)).

The term Dv,a∙ρg/ρl from Eq. (26) for C2–C9 n-alkanes for different temperatures

Figure 11 shows the trends of BM, which decreases at low and increases at high temperatures with pressure. At moderate temperature, BM is independent of pressure. The same trends can be observed for Yv,s and pv,s/p∞, resulting from Eq. (1). pv,s increases with increasing ambient pressure as the droplet surface temperature increases, however, the increase is more significant at higher temperatures as that temperature range is characterized by the upper part of the vapor pressure curve, as shown by Fig. 12.

Figure 13 shows the variation of λst. The diverging trends of ρl and BM for different temperatures lead to a diverging trend in λst as well, therefore increasing pr has a more significant effect at higher Tr. This behavior is more obvious by introducing the non-dimensional steady-state evaporation rate, Λst, which is the ratio of the pressure-dependent steady-state evaporation rate to the steady-state evaporation rate at 1 bar ambient pressure and the same ambient temperature, defined by Eq. (29):

Figure 14 shows the trends of Λst. Saturation can be observed at lower Tr, therefore, further increasing pr leads to only a slight enhancement of droplet vaporization. On the other hand, increasing pressure at high ambient temperature notably improves evaporation.

Figure 15 shows that Λst of C2–C9 n-alkanes is similar in the range of 1.3 ≤ Tr ≤ 1.5, allowing curve fitting by using LCS for calculating λst. Power function in the form of Λst = a(Tr)·prb(Tr) + c gave a satisfactory fit. a(Tr) and b(Tr) functions both took a similar form, α·Trβ + γ, leading to Eq. (30):

The validity of Eq. (30) is 0.02 ≤ pr ≤ 0.5, 1.3 ≤ Tr ≤ 1.5, and n-alkanes of C2–C9. The parameters of the curve fitting can be found in "Appendix 2" . The uncertainty of the present model is discussed in "Appendix 3" , considering the uncertainty of the material data, including cross-sensitivity.

With Eq. (30), the steady-state non-dimensional evaporation rate can be calculated with two parameters, Tc and pc. Thus, given the atmospheric evaporation characteristics, the steady-state evaporation rate of the droplet can be obtained for a given pressure and temperature in the validity range. As forced convection enhances vaporization, the calculated evaporation rate can be corrected by Re with a proper Nu and Sh correction factor (Lefebvre and McDonell 2017; Sazhin 2014), thus Eq. (30) is applicable for spray calculations in general.

4 Conclusions

The effect of ambient pressure and temperature on the characteristics of the steady-state evaporation rate of eleven different n-alkane droplets has been investigated by comparing the versatile steady-state d2-law with a transient evaporation model used in the state-of-the-art numerical codes. The material properties of the fluids were acquired from the NIST database. The range of pressure and temperature was defined as reduced values by using the critical properties. Based on the results, the following conclusions were derived:

-

1.

For small droplets (d0 ≈ 5–10 μm), the deviation between steady-state and transient models can be neglected. In this case, Nu and Sh are practically independent of droplet size, therefore the steady-state evaporation rate only depends on the thermophysical properties of the fluid.

-

2.

Lewis number notably exceeds unity during the transient heat-up period and remains above one for the steady-state evaporation for the investigated n-alkanes. Higher values correspond to low pressure and low temperature. Consequently, revising the Lewis number, even in a simple case, is highly recommended to avoid a notable bias.

-

3.

The ratio of vapor specific heat capacity to mixture specific heat capacity increases with pressure and decreases with temperature, like cp,v significantly rises with pressure closer to the critical temperature.

-

4.

The trends of term Dv,a∙ρg/ρl from Eq. (26) for C2–C9 n-alkanes are practically identical, however ethane shows a larger deviation at low temperature. This decreases with increasing the ambient temperature.

-

5.

BM decreases at low temperature and increases at high temperature with pressure, because of pv,s/p∞ increases at high, and decreases at low temperatures with pressure.

-

6.

λst increases with pressure, however the increase is more significant at higher temperatures due to the enhanced increment in pv,s/p∞ and the decrease in ρl.

-

7.

The non-dimensional evaporation rate, Λst, is practically identical for C2–C9 n-alkanes at 0.02 ≤ pr ≤ 0.5, 1.3 ≤ Tr ≤ 1.5, allowing to apply a two-parameter corresponding states method by using Eq. (30).

Abbreviations

- B M :

-

Spalding mass transfer number

- B T :

-

Spalding heat transfer number

- c p :

-

Specific heat capacity at constant pressure

- D :

-

Binary diffusion coefficient

- d :

-

Droplet diameter

- Gr:

-

Grashof number

- k :

-

Thermal conductivity

- L :

-

Latent heat of vaporization

- Le:

-

Lewis number

- \(\dot{m}_{d}\) :

-

Mass flow rate of vapor at the droplet surface

- M :

-

Molar mass

- Nu:

-

Nusselt number

- p :

-

Pressure

- RaM :

-

Rayleigh number for mass transfer

- RaT :

-

Rayleigh number for heat transfer

- Re:

-

Reynolds number

- Sc:

-

Schmidt number

- Sh:

-

Sherwood number

- T :

-

Temperature

- t :

-

Time

- Y :

-

Mass fraction

- β :

-

Thermal expansion coefficient of mixture

- Λ :

-

Non-dimensional evaporation rate

- λ :

-

Evaporation rate

- μ :

-

Dynamic viscosity

- ρ :

-

Density

- σ :

-

Deviation

- 0 :

-

Initial value

- 15% :

-

15% of the initial value

- ∞ :

-

Ambient

- a :

-

Air

- bn :

-

Normal boiling point

- c :

-

Critical

- d :

-

Droplet

- g :

-

Fuel vapor-air mixture

- l :

-

Liquid

- r :

-

Reduced value

- s :

-

Surface of droplet

- st :

-

Steady-state

- v :

-

Fuel vapor

References

Abramzon, B., Sirignano, W.A.: Droplet vaporization model for spray combustion calculations. Int. J. Heat Mass Transf. 32, 1605–1618 (1989). https://doi.org/10.1016/0017-9310(89)90043-4

AlZahrani, A.A., Dincer, I.: Modeling of n-Hexane and n-Octane liquid fuel jets in gaseous crossflow for evaporation, combustion and breakup evaluation. Int. Commun. Heat Mass Transf. 88, 203–210 (2017). https://doi.org/10.1016/j.icheatmasstransfer.2017.08.015

Ansys Fluent Theory Guide 2020 R1. (2020)

Bergman, T.L., Lavine, A.S., Incropera, F.P., DeWitt, D.P.: Fundamentals of Heat and Mass Transfer. Wiley, Hoboken (2017)

Borghesi, G., Krisman, A., Lu, T., Chen, J.H.: Direct numerical simulation of a temporally evolving air/n-dodecane jet at low-temperature diesel-relevant conditions. Combust. Flame. 195, 183–202 (2018). https://doi.org/10.1016/j.combustflame.2018.02.020

Chauveau, C., Birouk, M., Gökalp, I.: An analysis of the d2-law departure during droplet evaporation in microgravity. Int. J. Multiph. Flow. 37, 252–259 (2011). https://doi.org/10.1016/j.ijmultiphaseflow.2010.10.009

Chauveau, C., Birouk, M., Halter, F., Gökalp, I.: An analysis of the droplet support fiber effect on the evaporation process. Int. J. Heat Mass Transf. 128, 885–891 (2019). https://doi.org/10.1016/j.ijheatmasstransfer.2018.09.029

Chiaramonti, D.: Sustainable aviation fuels: the challenge of decarbonization. Energy Procedia 158, 1202–1207 (2019). https://doi.org/10.1016/j.egypro.2019.01.308

Chung, S.S., Kawaguchi, O.: Evaporation rate of free paraffin hydrocarbon droplets in a high-temperature and high-pressure gas stream. JSME Int. J. Ser. B. 38, 121–128 (1995). https://doi.org/10.1299/jsmeb.38.121

Chung, T.H., Lee, L.L., Starling, K.E.: Applications of kinetic gas theories and multiparameter correlation for prediction of dilute gas viscosity and thermal conductivity. Ind. Eng. Chem. Fundam. 23, 8–13 (1984). https://doi.org/10.1021/i100013a002

Chung, T.H., Ajlan, M., Lee, L.L., Starling, K.E.: Generalized multiparameter correlation for nonpolar and polar fluid transport properties. Ind. Eng. Chem. Res. 27, 671–679 (1988). https://doi.org/10.1021/ie00076a024

Ciottoli, P.P., Battista, F., Malpica Galassi, R., Dalla Barba, F., Picano, F.: Direct Numerical Simulations of the Evaporation of Dilute Sprays in Turbulent Swirling Jets. Flow Turbul. Combust. (2020). https://doi.org/10.1007/s10494-020-00200-7

Coleman, H.W., Steele, W.G.: Experimentation, Validation, and Uncertainty Analysis for Engineers. Wiley, Hoboken (2018)

Constantinou, L., Gani, R.: New group contribution method for estimating properties of pure compounds. AIChE J. 40, 1697–1710 (1994). https://doi.org/10.1002/aic.690401011

Constantinou, L., Gani, R., O’Connell, J.P.: Estimation of the acentric factor and the liquid molar volume at 298 K using a new group contribution method. Fluid Phase Equilib. 103, 11–22 (1995). https://doi.org/10.1016/0378-3812(94)02593-P

Csemány, D., Józsa, V.: Fuel Evaporation in an Atmospheric Premixed Burner: Sensitivity Analysis and Spray Vaporization. Processes 5(4), 80 (2017). https://doi.org/10.3390/pr5040080

Deneyer, A., Renders, T., Van Aelst, J., Van den Bosch, S., Gabriëls, D., Sels, B.F.: Alkane production from biomass: chemo-, bio- and integrated catalytic approaches. Curr. Opin. Chem. Biol. 29, 40–48 (2015). https://doi.org/10.1016/j.cbpa.2015.08.010

Directive (EU): 2015/2193 of the European Parliament and of the Council on the limitation of emissions of certain pollutants into the air from medium combustion plants. Off. J. Eur. Union 313, 1–19 (2015)

Elbro, H.S., Fredenslund, A., Rasmussen, P.: Group contribution method for the prediction of liquid densities as a function of temperature for solvents, oligomers, and polymers. Ind. Eng. Chem. Res. 30, 2576–2582 (1991). https://doi.org/10.1021/ie00060a011

Ewender, J., Welle, F.: Diffusion coefficients of n-Alkanes and 1-Alcohols in Polyethylene Naphthalate (PEN). Int. J. Polym. Sci. 2019, 2748649 (2019). https://doi.org/10.1155/2019/2748649

Fang, B., Chen, L., Li, G., Wang, L.: Multi-component droplet evaporation model incorporating the effects of non-ideality and thermal radiation. Int. J. Heat Mass Transf. 136, 962–971 (2019). https://doi.org/10.1016/j.ijheatmasstransfer.2019.03.051

Fuchs, N.A.: Evaporation and Droplet Growth in Gaseous Media. Pergamon Press, Oxford (1959)

Fuller, E.N., Schettler, P.D., Giddings, J.C.: New method for prediction of binary gas-phase diffusion coefficients. Ind. Eng. Chem. 58, 18–27 (1966). https://doi.org/10.1021/ie50677a007

Fuller, E.N., Ensley, K., Giddings, J.C.: Diffusion of halogenated hydrocarbons in helium. The effect of structure on collision cross sections. J. Phys. Chem. 73, 3679–3685 (1969). https://doi.org/10.1021/j100845a020

Ghassemi, H., Baek, S., Sarwar Khan, Q.: Experimental study on binary droplet evaporation at elevated pressures and temperatures. Combust Sci Technol 178(6), 1031–1053 (2006)

Godsave, G.A.E.: Studies of the combustion of drops in a fuel spray-the burning of single drops of fuel. Symp. Combust. 4, 818–830 (1953). https://doi.org/10.1016/S0082-0784(53)80107-4

Hillenbrand, T., Brüggemann, D.: Evaporation of free falling droplets of binary alkane-ethanol blends. Fuel 274, 117869 (2020). https://doi.org/10.1016/j.fuel.2020.117869

Joback, K.G.: A Unified Approach to Physical Property Estimation Using Multivariate Statistical Techniques. Massachusetts Institute of Technology Department of Chemical Engineering, Cambridge (1984)

Joback, K.G., Reid, R.C.: Estimation of pure-component properties from group-contributions. Chem. Eng. Commun. 57, 233–243 (1987). https://doi.org/10.1080/00986448708960487

Jung, J., Park, S., Bae, C.: Combustion characteristics of gasoline and n-butane under lean stratified mixture conditions in a spray-guided direct injection spark ignition engine. Fuel 187, 146–158 (2017). https://doi.org/10.1016/j.fuel.2016.08.085

Kibria, A., Akhundjanov, S.B., Oladi, R.: Fossil fuel share in the energy mix and economic growth. Int. Rev. Econ. Financ. 59, 253–264 (2019). https://doi.org/10.1016/j.iref.2018.09.002

Lefebvre, A.H., McDonell, V.G.: Atomization and Sprays. CRC Press, Taylor & Francis Group, Boca Raton (2017)

Lemmon, E.W., McLinden, M.O., Friend, D.G.: Thermophysical Properties of Fluid Systems, NIST Chemistry WebBook, NIST Standard Reference Database Number 69 (2019). https://doi.org/10.18434/T4D303

Lødeng, R., Lunder, O., Lein, J.-E., Dahl, P.I., Svenum, I.-H.: Synthesis of light olefins and alkanes on supported iron oxide catalysts. Catal. Today 299, 47–59 (2018). https://doi.org/10.1016/j.cattod.2017.06.039

Lopez-Echeverry, J.S., Reif-Acherman, S., Araujo-Lopez, E.: Peng-Robinson equation of state: 40 years through cubics. Fluid Phase Equilib. 447, 39–71 (2017). https://doi.org/10.1016/j.fluid.2017.05.007

Nguyen, T.T.B., Mitra, S., Sathe, M.J., Pareek, V., Joshi, J.B., Evans, G.M.: Evaporation of a suspended binary mixture droplet in a heated flowing gas stream. Exp. Therm. Fluid Sci. 91, 329–344 (2018). https://doi.org/10.1016/j.expthermflusci.2017.10.025

Nomura, H., Murakoshi, T., Suganuma, Y., Ujiie, Y., Hashimoto, N., Nishida, H.: Microgravity experiments of fuel droplet evaporation in sub- and supercritical environments. Proc. Combust. Inst. 36, 2425–2432 (2017). https://doi.org/10.1016/j.proci.2016.08.046

Pal, M.K., Bakshi, S.: Effect of ambient fuel vapour concentration on the vapour penetration of evaporating n-hexane sprays. Fuel 223, 179–187 (2018). https://doi.org/10.1016/j.fuel.2018.02.193

Pérez-Roca, S., Marzat, J., Piet-Lahanier, H., Langlois, N., Farago, F., Galeotta, M., Le Gonidec, S.: A survey of automatic control methods for liquid-propellant rocket engines. Prog. Aerosp. Sci. 107, 63–84 (2019). https://doi.org/10.1016/j.paerosci.2019.03.002

Pinheiro, A.P., Vedovoto, J.M.: Evaluation of droplet evaporation models and the incorporation of natural convection effects. Flow Turbul. Combust. 102, 537–558 (2019). https://doi.org/10.1007/s10494-018-9973-8

Poling, B.E., Prausnitz, J.M., O’Connell, J.P.: The Properties of Gases and Liquids. McGraw-Hill, New York (2001)

Poulton, L., Rybdylova, O., Zubrilin, I.A., Matveev, S.G., Gurakov, N.I., Al Qubeissi, M., Al-Esawi, N., Khan, T., Gun’ko, V.M., Sazhin, S.S. : Modelling of multi-component kerosene and surrogate fuel droplet heating and evaporation characteristics: a comparative analysis. Fuel 269, 117115 (2020). https://doi.org/10.1016/j.fuel.2020.117115

Ray, S., Raghavan, V.: Numerical study of evaporation characteristics of biodiesel droplets of Indian origin. Fuel 271, 117637 (2020). https://doi.org/10.1016/j.fuel.2020.117637

Savard, B., Wang, H., Wehrfritz, A., Hawkes, E.R.: Direct numerical simulations of rich premixed turbulent n-dodecane/air flames at diesel engine conditions. Proc. Combust. Inst. 37, 4655–4662 (2019). https://doi.org/10.1016/j.proci.2018.08.022

Sazhin, S.: Droplets and Sprays. Springer, London (2014)

Sazhin, S.S.: Modelling of fuel droplet heating and evaporation: Recent results and unsolved problems. Fuel 196, 69–101 (2017). https://doi.org/10.1016/j.fuel.2017.01.048

Spalding, D.B.: The combustion of liquid fuels. Symp. Combust. 4, 847–864 (1953). https://doi.org/10.1016/S0082-0784(53)80110-4

VDI e. V. ed: VDI Heat Atlas. Springer, Berlin, Heidelberg (2010)

Svehla, R.A.: Estimated viscosities and thermal conductivities of gases at high temperatures. NASA Tech. Rept. R-132, Lewis Research Center, Cleveland, Ohio (1962)

Urbán, A., Zaremba, M., Malý, M., Józsa, V., Jedelský, J.: Droplet dynamics and size characterization of high-velocity airblast atomization. Int. J. Multiph. Flow. 95, 1–11 (2017). https://doi.org/10.1016/j.ijmultiphaseflow.2017.02.001

Urbán, A., Malý, M., Józsa, V., Jedelský, J.: Effect of liquid preheating on high-velocity airblast atomization: From water to crude rapeseed oil. Exp. Therm. Fluid Sci. 102, 137–151 (2019). https://doi.org/10.1016/j.expthermflusci.2018.11.006

Verwey, C., Birouk, M.: Experimental investigation of the effect of natural convection on the evaporation characteristics of small fuel droplets at moderately elevated temperature and pressure. Int. J. Heat Mass Transf. 118, 1046–1055 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.038

Winkelmann, J.: Landolt-Börnstein-Group IV Physical Chemistry. Presented at the January (2007)

Wu, Y., Zhu, M., Ye, T., Zhou, T., Tang, P.: Numerical simulation of the effects of evaporation on the n-heptane/air auto-ignition process under different initial air temperatures. Fuel 243, 202–209 (2019). https://doi.org/10.1016/j.fuel.2019.01.082

Yang, J.-R., Wong, S.-C.: On the discrepancies between theoretical and experimental results for microgravity droplet evaporation. Int. J. Heat Mass Transf. 44, 4433–4443 (2001). https://doi.org/10.1016/S0017-9310(01)00091-6

Yang, J.-R., Wong, S.-C.: An experimental and theoretical study of the effects of heat conduction through the support fiber on the evaporation of a droplet in a weakly convective flow. Int. J. Heat Mass Transf. 45, 4589–4598 (2002). https://doi.org/10.1016/S0017-9310(02)00164-3

Acknowledgements

The authors are grateful to Gábor Halász for the valuable discussions on uncertainty analysis.

Funding

Open Access funding provided by Budapest University of Technology and Economics. The research reported in this paper and carried out at the Budapest University of Technology and Economics has been supported by the National Research Development and Innovation Fund (TKP2020 National Challenges Subprogram, Grant No. BME-NC) based on the charter of bolster issued by the National Research Development and Innovation Office under the auspices of the Ministry for Innovation and Technology and project №. OTKA-FK 124704, New National Excellence Program of the Ministry of Human Capacities project №.s ÚNKP-18–4-BME-195 and ÚNKP-18–3-I-BME-145, New National Excellence Program of the Ministry for Innovation and Technology project №.s ÚNKP-19–3-I-BME-236 and ÚNKP-19–4-BME-213, and the János Bolyai Research Scholarship of the Hungarian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Appendices

Appendix 1: Validation of the Evaporation Model

The present results are validated against ref. (Chung and Kawaguchi 1995) where the evaporation of d0 = 200 μm n-heptane droplets is investigated using a drop tower. The velocity of the droplets and the air stream are almost equal, thus the reported value of Re is 0.3. Figure 16 shows the comparison between the free-falling droplet measurement data and calculation. A correction factor was introduced in order to consider forced convection, therefore the calculated steady-state evaporation rate values were multiplied by a factor of (1 + 0.3Re1/2Sc1/3) according to the Sh correction (Lefebvre and McDonell 2017). Calculated λst values show a good agreement with measurement data. Only a small discrepancy can be observed. Note that model validation with suspended droplet measurements is more challenging and requires special attention as the heat balance of the droplet is notably affected by the support fiber, resulting in an enhanced vaporization rate (Yang and Wong 2001,2002; Chauveau et al. 2019). Presently, no experimental data was used from this latter measurement type.

Appendix 2: Curve Fitting Parameters of the Non-Dimensional Steady-State Evaporation Rate

Tables 2 and 3 contain the parameters of the curve fitting of Eq. (30). These parameters are the a, b, c, α, β, and γ coefficients and their upper and lower confidence bounds (cb + and cb− respectively).

Appendix 3: Uncertainty Analysis of Λ st

Table 4 summarizes the relative uncertainty of each material property for the different n-alkanes. Note that the binary diffusion coefficient is calculated with Eq. (5), thus uncertainty values corresponding to Dv,a refer to measurement data of n-alkane-nitrogen systems from ref. (Winkelmann 2007), as no uncertainty data was available for the method of Fuller. Air composition was 21 V/V% O2 and 79 V/V% N2. Λst is the ratio of the steady-state evaporation rate to the steady-state evaporation rate at 1 bar ambient pressure. According to Eq. (29), the corresponding material properties (e.g., vapor density at a given pressure and 1 bar) in the numerator and denominator are correlated, resulting in a final reduction of the deviation of Λst due to the cross-correlation terms, which were assumed to be unity for the identical material properties. Consequently, the data uncertainty can be lower than the uncertainty of each value if they are correlated as long as the sign of the cross derivatives multiplied by the correlation of the two quantities is negative. The deviation of Λst was determined by Eq. (31) (Coleman and Steele 2018):

where corr(xi, xj) = 1, when i = j or xi and xj are identical variables, otherwise corr(xi, xj) = 0. The values of the relative error are shown by Fig. 17 for C2–C9 n-alkanes, which are well below 1% for all the investigated conditions, because of the very low relative uncertainty of vapor-phase and liquid-phase densities, and the correlated quantities.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Csemány, D., Józsa, V. A Two-Parameter Corresponding States Method for Calculating the Steady-State Evaporation Rate of C2–C9 n-Alkane Droplets in Air for Elevated Pressures and Temperatures. Flow Turbulence Combust 107, 283–305 (2021). https://doi.org/10.1007/s10494-020-00238-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10494-020-00238-7