Abstract

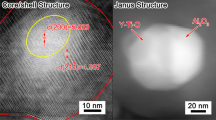

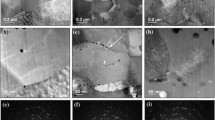

This study presents the fabrication of 14Cr Fe–Cr–Al oxide dispersion strengthened (ODS) alloy by a direct oxidation process. In order to explain how oxide nanoparticles are formed in the consolidation process, the powders after oxidation are subjected to vacuum thermal treatment at high temperatures. Differential scanning calorimeter, X-ray photoelectron spectroscopy, scanning electron microscopy and transmission electron microscopy techniques are used to detect the generation, evolution of oxides on both the surface and interior of the powder, as well as the type of oxide nanoparticles in the fabricated ODS alloy. It is found that an iron oxide layer is formed on the surface of the powder during low temperature oxidation. And the iron oxide layer would be decomposed after thermal treatment at high temperature. In the consolidation process, the oxygen required by the reaction of alumina and yttrium oxide to produce nanoscale Y–Al–O particles mainly derives from the decomposition of iron oxide layer at elevated temperature and the inward diffusion of oxygen. Using the direct oxidation process, YAlO3 nanoparticles are dispersed in the grains and at the grain boundaries of Fe–Cr–Al ODS alloy.

Similar content being viewed by others

References

T. Allen, J. Busby, M. Meyer, D. Petti, Mater. Today 13, 14 (2010)

S.K. Karak, T. Chudoba, Z. Witczak, W. Lojkowski, I. Manna, Mater. Sci. Eng. A 528, 7475 (2011)

P. Dou, A. Kimura, T. Okuda, M. Inoue, S. Ukai, S. Ohnuki, T. Fujisawa, F. Abe, Acta Mater. 59, 992 (2011)

A. Kimura, R. Kasada, N. Iwata, H. Kishimoto, C.H. Zhang, J. Isselin, P. Dou, J.H. Lee, N. Muthukumar, T. Okuda, M. Inoue, S. Ukai, S. Ohnuki, T. Fujisawa, T.F. Abe, J. Nucl. Mater. 417, 176 (2011)

H. Shibata, S. Ukai, N.H. Oono, K. Sakamoto, M. Hirai, J. Nucl. Mater. 502, 228 (2018)

S.J. Zinkle, G.S. Was, Acta Mater. 61, 735 (2013)

Z. Zhang, W. Pantleon, Acta Mater. 149, 235 (2018)

Q. Zhao, L. Yu, Y. Liu, Y. Huang, Q. Guo, H. Li, J. Wu, Powder Technol. 311, 449 (2017)

C. Suryanarayana, E. Ivanov, Adv. Powder Metall. 3, 42 (2013)

Z. Hong, X. Zhang, Q. Yan, Y. Chen, J. Alloys Compd. 770, 831 (2019)

L.K. Mansur, A.F. Rowcliffe, R.K. Nanstad, S.J. Zinkle, W.R. Corwin, R.E. Stoller, J. Nucl. Mater. 329–333, 166 (2004)

J.R. Rieken, I.E. Anderson, M.J. Kramer, G.R. Odette, E. Stergar, E. Haney, J. Nucl. Mater. 428, 65 (2012)

E. Gil, J. Cortés, I. Iturriza, N. Ordás, Appl. Surf. Sci. 427, 182 (2018)

E. Gil, N. Ordás, C. García-Rosales, I. Iturriza, Fusion Eng. Des. 98–99, 1973 (2015)

J. Li, S. Wu, P. Ma, Y. Yang, E. Wu, L. Xiong, S. Liu, Mater. Sci. Eng. A 757, 42 (2019)

R.J. Miller, A. Gangulee, J. Vac. Sci. Technol. 15, 244 (1978)

K. Nakamura, M. Kamoshida, J. Appl. Phys. 48, 5349 (1977)

C.M. Wang, G.S. Cargill, H.M. Chan, M.P. Harmer, Acta Mater. 48, 2579 (2000)

A.M. Thompson, K.K. Soni, H.M. Chan, M.P. Harmer, D.B. Williams, J.M. Chabala, R. Levi-Setti, J. Am. Ceram. Soc. 80, 373 (1997)

C.L. Briant, K.L. Luthra, Metall. Trans. A 19 A, 2099 (1988)

J. Wang, S. Liu, X. Bai, X. Zhou, X. Han, Vacuum 173, 109144 (2020)

C.L. Briant, R.A. Mulford, Metall. Trans. A 13, 745 (1982)

L.P.H. Jeurgens, W.G. Sloof, F.D. Tichelaar, E.J. Mittemeijer, Surf. Sci. 506, 313 (2002)

S. Wu, J. Li, W. Li, S. Liu, J. Alloys Compd. 814, 152282 (2020)

C.L. Chen, Y.M. Dong, Mater. Sci. Eng. A 528, 8374 (2011)

K. Nomura, Y. Ujihira, J. Mater. Sci. 25, 1745 (1990)

T. Kosaka, S. Suzuki, H. Inoue, M. Saito, Y. Waseda, E. Matsubara, Appl. Surf. Sci. 103, 55 (1996)

G. Betz, G.K. Wehner, L. Toth, A. Joshi, J. Appl. Phys. 45, 5312 (1974)

M. Medraj, R. Hammond, M.A. Parvez, R.A.L. Drew, W.T. Thompson, J. Eur. Ceram. Soc. 26, 3515 (2006)

D. Pazos, M. Suárez, A. Fernández, P. Fernández, I. Iturriza, N. Ordás, Fusion Eng. Des. 146, 2328 (2019)

K. Dawson, S.J. Haigh, G.J. Tatlock, A.R. Jones, J. Nucl. Mater. 464, 200 (2015)

Acknowledgements

This work was supported by the National Defense Science and Technology Industry Nuclear Material Technology Innovation Center Project (No. ICNM-2020-ZH-17).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Yan, F., Li, J., Li, Y. et al. Formation Mechanism of Nanoparticles in Fe–Cr–Al ODS Alloy Fabricated by Direct Oxidation Method. Acta Metall. Sin. (Engl. Lett.) 34, 963–972 (2021). https://doi.org/10.1007/s40195-020-01184-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01184-z