Abstract

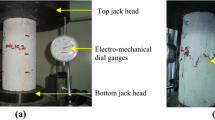

This research aims to experimentally evaluate the behaviour of multi-layered fibrous cementitious composites with intermediate Glass Fibre Meshes (GFM) under repeated projectile load. The impact load was subjected through a convex edge projectile needle at a low velocity on cylindrical specimens of three-layered fibrous cementitious composites, which have two different steel fibre distributions. In series A mixtures, a constant steel fibre dosage of 2.5% by volume was used. On the other hand, the fibre dosage of the outer layers was 3.0%; while it was 1.5% in the middle layer of series B mixtures. The number of intermediate GFM was the variable that distinguishes the mixtures of each series. The resistance to projectile impacts was evaluated on the basis of penetration depth, near surface distortion, weight loss, damage ratio and failure pattern. The test results showed that due to the combined effect of steel fibre and GFM, significantly lower weight losses were recorded for series A and B specimens compared with reference specimens. However, the different fibre distributions (series B) led to lower penetration depths and weight losses with less surface distortion compared with the fixed fibre distribution (series A). The reduction in the destroyed front surface area of series A specimens compared with reference specimens ranged from 27.8 to 38.1%; while that of series B specimens ranged from 34.8 to 53.4%. In addition, a simplified analytical model was introduced to predict the ejected composite mass. The model predictions were found to be in good agreement with the experimental masses.

Similar content being viewed by others

References

Wu H, Fang Q, Chen XW, Gong ZM, Liu JZ (2015) Projectile penetration of ultrahigh performance cement based composites at 510–1320 m/s. Constr Build Mater 74:188–200. https://doi.org/10.1016/j.conbuildmat.2014.10.041

Wen HM, Xian YX (2015) A unified approach for concrete impact. Int J Impact Eng 77:84–96. https://doi.org/10.1016/j.ijimpeng.2014.11.015

Sovjak R, Vavriník T, Zatloukal J, Maca P, Micunek T, Frydrýn M (2015) Resistance of slim UHPFRC targets to projectile impact using in-service bullets. Int J Impact Eng 76:166–177. https://doi.org/10.1016/j.ijimpeng.2014.10.002

Salaimanimagudam MP, Suribabu CR, Murali G, Abid SR (2020) Impact response of hammerhead pier fibrous concrete beams designed with topology optimization. Period Polytech Civil Eng 64(4):1244–1258. https://doi.org/10.3311/PPci.16664

Abid SR, Abdul-Hussein ML, Ayoob NS, Ali SH, Kadhum AL (2020) Repeated drop-weight impact tests on self-compacting concrete reinforced with micro-steel fiber. Heliyon 6:1–11. https://doi.org/10.1016/j.heliyon.2020.e03198

ACI 304.1 (2005) Guide for the use of preplaced aggregate concrete for structural and mass concrete applications. American Concrete Institute, ACI Committee 304, USA

Abdelgader HS (1999) How to design concrete produced by a two-stage concreting method. Cem Concr Res 29(3):311–337. https://doi.org/10.1016/S0008-8846(98)00215-4

Najjar MF, Soliman AM, Nehdi ML (2014) Critical overview of two-stage concrete: properties and applications. Constr Build Mater 62:47–58. https://doi.org/10.1016/j.conbuildmat.2014.03.021

Yoon JY, Kim JH (2019) Mechanical properties of preplaced lightweight aggregates concrete. Constr Build Mater 216:440–449. https://doi.org/10.1016/j.conbuildmat.2019.05.010

O’Malley J, Abdelgader HS (2010) Investigation into the viability of using two stage (pre-placed aggregate) concrete in an Irish setting. Front Arch Civ Eng China 4(1):127–132. https://doi.org/10.1007/s11709-010-0007-4

Abdelgader HS, Górski J (2003) Stress-strain relations and modulus of elasticity of two-stage concrete. J Mater Civ Eng 15(4):329–334. https://doi.org/10.1061/(ASCE)0899-1561(2003)15:4(329)

Lin S, Shams S, Choi H, Azari H (2018) Ultrasonic imaging of multi-layer concrete structures. NDT E Int 98:101–109. https://doi.org/10.1016/j.ndteint.2018.04.012

Haridharan MK, Matheswaran S, Murali G, Abid SR, Fediuk R, Amran YH, Abdelgader HS (2020) Impact response of two-layered grouted aggregate fibrous concrete composite under falling mass impact. Constr Build Mater 263:120628. https://doi.org/10.1016/j.conbuildmat.2020.120628

Li PP, Sluijsmans MJC, Brouwers HJH, Yu QL (2020) Functionally graded ultra-high performance cementitious composite with enhanced impact properties. Compos Part B Eng 183:107680. https://doi.org/10.1016/j.compositesb.2019.107680

Ramkumar VR, Murali G, Asrani NP, Karthikeyan K (2019) Development of a novel low carbon cementitious two stage layered fibrous concrete with superior impact strength. J Build Eng 25:100841. https://doi.org/10.1016/j.jobe.2019.100841

Murali G, Ramprasad K (2018) A feasibility of enhancing the impact strength of novel layered two stage fibrous concrete slabs. Eng Struct 175:41–49. https://doi.org/10.1016/j.engstruct.2018.08.034

Abid SR, Abdul-Hussein ML, Ali SH, Kazem AF (2020) Suggested modified testing techniques to the ACI 544-R repeated drop-weight impact test. Constr Build Mater 244(118321):2020. https://doi.org/10.1016/j.conbuildmat.2020.118321

Kurihashi Y, Kono K, Komuro M (2020) Response characteristics of a steel-fiber reinforced porosity-free concrete beam under impact load. Int J Civ Eng 18:673–684. https://doi.org/10.1007/s40999-020-00501-y

Li QM, Reid RS, Wen HM, Telford AR (2005) Local impact effects of hard missiles on concrete targets. Int J Impact Eng 32(1–4):224–284. https://doi.org/10.1016/j.ijimpeng.2005.04.005

Anderson CE Jr (2017) Analytical models for penetration mechanics: a review. Int J Impact Eng 108:3–26. https://doi.org/10.1016/j.ijimpeng.2017.03.018

Mu ZC, Zhang W, Wang W, Jiang NJ, Wu X (2020) Revising the penetration behavior of concrete-like and metal-like materials against the rigid projectile impact. Mech Mater 142:103274. https://doi.org/10.1016/j.mechmat.2019.103274

Lai JZ, Wang HF, Yang HR, Zheng XB, Wang Q (2017) Dynamic properties and SPH simulation of functionally graded cementitious composite subjected to repeated penetration. Constr Build Mater 146:54–65. https://doi.org/10.1016/j.conbuildmat.2017.04.023

Yu R, Spiesz P, Brouwers HJJ (2016) Energy absorption capacity of a sustainable Ultra-High Performance Fibre Reinforced Concrete (UHPFRC) in quasi-static mode and under high velocity projectile impact. Cement Concr Compos 68:109–122. https://doi.org/10.1016/j.cemconcomp.2016.02.012

Sukontasukkul P, Jamnam S, Rodsin K, Banthia N (2013) Use of rubberized concrete as a cushion layer in bulletproof fiber reinforced concrete panels. Constr Build Mater 41:801–811. https://doi.org/10.1016/j.conbuildmat.2012.12.068

Máca P, Sovják R, Konvalinka P (2014) Mix design of UHPFRC and its response to projectile impact. Int J Impact Eng 63:158–163. https://doi.org/10.1016/j.ijimpeng.2013.08.003

Zhang M, Shim V, Lu G, Chew C (2005) Resistance of high-strength concrete to projectile impact. Int J Impact Eng 31(7):825–841. https://doi.org/10.1016/j.ijimpeng.2004.04.009

Tai Y (2009) Flat ended projectile penetrating ultra-high strength concrete plate target. Theoret Appl Fract Mech 51(2):117–128. https://doi.org/10.1016/j.tafmec.2009.04.005

O’Neil E, Neeley B, Cargile J (1999) Tensile properties of very-high-strength concrete for penetration-resistant structures. Shock Vib 6(5):237–245. https://doi.org/10.1155/1999/415360

Farnam Y, Mohammadi S, Shekarchi M (2010) Experimental and numerical investigations of low velocity impact behaviour of high performance fibre reinforced cement based composite. Int J Impact Eng 37(2):220–229. https://doi.org/10.1016/j.ijimpeng.2009.08.006

Tasdemirci A, Hall IW (2009) Development of novel multilayer materials for impact applications: a combined numerical and experimental approach. Mater Des 30(5):1533–1541. https://doi.org/10.1016/j.matdes.2008.07.054

Shirai T, Kambayashi A, Ohno T, Taniguchi H, Ueda M, Ishikawa N (1997) Experiment and numerical simulation of double-layered RC plates under impact loadings. Nucl Eng Des 176(3):195–205. https://doi.org/10.1016/S0029-5493(97)00142-8

Amde AM, Mirmiran A, Walter TA (1997) Local damage assessment of turbine missile impact on composite and multiple barriers. Nucl Eng Des 178(1):145–156. https://doi.org/10.1016/S0029-5493(97)00206-9

Zhang X, Li Y (2010) On the comparison of the ballistic performance of 10% zirconia toughened alumina and 95% alumina ceramic target. Mater Des 31(4):1945–1952. https://doi.org/10.1016/j.matdes.2009.10.046

Wang J, Zhou N (2013) Damage mechanism and anti-penetration performance of explosively welded plates impacted by projectiles with different shapes. Mater Des 49:966–973. https://doi.org/10.1016/j.matdes.2013.01.043

Kojima L (1991) An experimental study on local behavior of reinforced concrete slabs to missile impact. Nucl Eng Des 130(2):121–132. https://doi.org/10.1016/0029-5493(91)90121-W

Lai J, Yang H, Wang H, Zheng X, Wang Q (2019) Penetration experiments and simulation of three-layer functionally graded cementitious composite subjected to multiple projectile impacts. Constr Build Mater 196:499–511. https://doi.org/10.1016/j.conbuildmat.2018.11.154

Abirami T, Murali G, Mohan KSR, Salaimanimagudam MP, Nagaveni P, Bhargavi P (2020) Multi-layered two stage fibrous composites against low-velocity falling mass and projectile impact. Constr Build Mater 248:118631. https://doi.org/10.1016/j.conbuildmat.2020.118631

Bureau of Indian Standards (BIS) (2008) Code of practice for 53 Grade ordinary Portland cement. New Delhi: BIS; 1987. Standard No. IS-12269

Bureau of Indian Standards (BIS) (2002) Code of practice—specification for coarse and fine aggregate from natural sources for concrete: New Delhi: BIS; 1970. Standard No IS 383

American Society for Testing and Materials (ASTM) (2010) Standard test methods for flow of grout for preplaced-aggregate concrete (Flow cone method). West Conshohocken, PA: ASTM; 2010. Standard No. ASTM C939

Bureau of Indian Standards (BIS) (2008) Code of practice for Methods of test for aggregates for concrete: New Delhi: BIS; 1963. Standard No IS 2386 (Part 1 to VII: 2008)

ASTM C803/C803M-18, Standard Test Method for Penetration Resistance of Hardened Concrete, ASTM International, West Conshohocken, PA, 201

IS: 516–1959 (2004) Indian standard method of tests for strength of concrete. Reaffirmed

IS 5816 (1999) Indian Standard Splitting tensile strength of concrete—method of test (First Revision)

Ismail MK, Hassan AAA, Lachemi M (2018) Effect of fiber type on impact and abrasion resistance of engineered cementitious composite. ACI Mater J 115(6):957–968. https://doi.org/10.14359/51710960

Murali G, Abid SR, Amran YHM, Abdelgader HS, Fediuk R, Susrutha R, Poonguzhali K (2020) Impact performance of novel multi-layered prepacked aggregate fibrous composites under compression and bending. Structures 28:1502–1515. https://doi.org/10.1016/j.istruc.2020.10.001

Ding Y, Li D, Zhang Y, Azevedo C (2017) Experimental investigation on the composite effect of steel rebars and macro fibers on the impact behavior of high performance self-compacting concrete. Constr Build Mater 136:495–505. https://doi.org/10.1016/j.conbuildmat.2017.01.073

Nili M, Afroughsabet V (2010) Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int J Impact Eng 37:879–886. https://doi.org/10.1016/j.ijimpeng.2010.03.004

Bohara RP, Tanapornraweekit G, Tangtermsirikul S (2019) An experimental study on mechanical properties and cracking behaviors of AFRC used as functional material in hybrid beams. Int J Civ Eng 17:1433–1444. https://doi.org/10.1007/s40999-019-00404-7

Yoo D, Joo H, Young S (2013) Effect of fibre content on mechanical and fracture properties of ultra-high performance fibre reinforced cementitious composites. Compos Struct 106:742–753. https://doi.org/10.1016/j.compstruct.2013.07.033

Almusallam TH, Siddiqui NA, Iqbal RA, Abbas H (2013) Response of hybrid-fiber reinforced concrete slabs to hard projectile impact. Int J Impact Eng 58:17–30. https://doi.org/10.1016/j.ijimpeng.2013.02.005

Wang S, Zhang M, Quek S (2011) Tensile strength versus toughness of cement based materials against high-velocity projectile impact. Int J Prot Struct 2(2):207–219. https://doi.org/10.1260/2041-4196.2.2.207

Arna’ot FH, Abbass AA, Abualtemen AA, Abid SR, Özakça M (2017) Residual strength of high strength concentric column-SFRC flat plate exposed to high temperatures. Constr Build Mater 154:204–218. https://doi.org/10.1016/j.conbuildmat.2017.07.141

Smarzewski P, Barnat-Hunek D (2018) Property assessment of hybrid fiber-reinforced ultra-high performance concrete. Int J Civ Eng 16:593–606. https://doi.org/10.1007/s40999-017-0145-3

Abbass A, Abid S, Özakça M (2019) Experimental investigation on the effect of steel fibers on the flexural behavior and ductility of high-strength concrete hollow beams. Adv Civ Eng. https://doi.org/10.1155/2019/8390345

Quek ST, Lin VWJ, Maalej M (2010) Development of functionally-graded cementitious panel against high-velocity small projectile impact. Int J Impact Eng 37:928–941. https://doi.org/10.1016/j.ijimpeng.2010.02.002

Maho B, Sukontasukkul P, Jamnam S, Yamaguchi E, Fujikake K, Banthia N (2019) Effect of rubber insertion on impact behavior of multilayer steel fiber reinforced concrete bulletproof panel. Constr Build Mater 216:476–484. https://doi.org/10.1016/j.conbuildmat.2019.04.243

Acknowledgments

The authors would like to gratefully thank the School of Civil Engineering, SASTRA University for the support. The authors would also like to express their gratitude to Ms. T. Abirami, Mr. M.P. Salaimanimagudam, Ms. Parshyam Nagaveni and Ms. Pallem Bhargavi for assistance in casting and testing the specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Murali, G., Abid, S.R., Abdelgader, H.S. et al. Repeated Projectile Impact Tests on Multi-Layered Fibrous Cementitious Composites. Int J Civ Eng 19, 635–651 (2021). https://doi.org/10.1007/s40999-020-00595-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-020-00595-4