Abstract

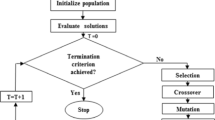

Genetic algorithm (GA) is used to solve a variety of optimization problems. Mutation operator also is responsible in GA for maintaining a desired level of diversity in the population. Here, a directional mutation operator is proposed for real-coded genetic algorithm (RGA) along with a directional crossover (DX) operator to improve its performance. These evolutionary operators use directional information to guide the search process in the most promising area of the variable space. The performance of an RGA with the proposed mutation operator and directional crossover (DX) is tested on six benchmark optimization problems of different complexities, and the results are compared to that of the RGAs with five other mutation schemes. The proposed IRGA is found to outperform other RGAs in terms of accuracy in the solutions, convergence rate, and computational time, which is established firmly through statistical analysis. Furthermore, the performance of the proposed IRGA is compared to that of a few recently proposed optimization algorithms. The proposed IRGA is seen to yield the superior results compared to that of the said techniques. It is also applied to solve five constrained engineering optimization problems, where again, it has proved its supremacy. The proposed mutation scheme using directional information leads to an efficient search, and consequently, a superior performance is obtained.

Similar content being viewed by others

Abbreviations

- \( N \) :

-

Population size

- \( p_{\text{c}} \) :

-

Crossover probability

- \( d \) :

-

Dimensions of an optimization problem

- \( \alpha \) :

-

Multiplying factor

- \( {\text{fe}} \) :

-

Number of function evaluation

- \( t_{\text{avg}} \) :

-

Average CPU time

- \( Q_{ \hbox{min} } \) :

-

Minimum frequency

- \( D \) :

-

Mean diameter

- \( \tau \) :

-

Shear stress

- \( P_{\text{c}} \) :

-

Buckling load on the beam

- \( T_{\text{s}} \) :

-

Shell thickness

- \( r_{\text{i}} \) :

-

Inner radius

- \( b \) :

-

Face width

- \( z \) :

-

Number of teeth on the pinion

- \( d_{1} \), \( d_{2} \) :

-

Diameters of the first and second shafts, respectively

- \( r_{\text{m}} \) :

-

Mean radius of particles

- \( {\text{MRR}} \) :

-

Material removal rate

- \( \rho_{\text{w}} \) :

-

Density of work material

- \( H_{\text{dw}} \) :

-

Dynamic hardness of ductile work material

- \( (R_{\text{a}} )_{\hbox{max} } \) :

-

Permissible surface roughness

- \( p_{\text{m}} \) :

-

Mutation probability

- \( p_{\text{cv}} \) :

-

Variablewise crossover probability

- \( p_{\text{best}} \) :

-

Current best solution

- \( p_{\text{mean}} \) :

-

Average of two parents \( p_{1} \) and \( p_{2} \)

- \( \hbox{max} \_{\text{gen}} \) :

-

Maximum number of generations

- \( {\text{fe}}_{\text{avg}} \) :

-

Average number of function evaluations

- \( d_{\text{w}} \) :

-

Wire diameter

- \( n \) :

-

Number of active coils

- \( \theta \) :

-

Bending stress

- \( \delta \) :

-

End deflection of a bar

- \( T_{\text{h}} \) :

-

Thickness of head

- \( l \) :

-

Length of the cylindrical vessel

- \( m \) :

-

Module of teeth

- \( L_{1} \), \( L_{2} \) :

-

Lengths of the first and second shafts between bearings, respectively

- \( \dot{M}_{\text{a}} \) :

-

Mass flow rate of abrasives

- \( v_{\text{a}} \) :

-

Velocity of abrasives

- \( \rho_{\text{a}} \) :

-

Density of abrasives

- \( \delta_{\text{cw}} \) :

-

Critical plastic strain of ductile work material

- \( \zeta \) :

-

Amount of plastically deformed indentation volume

- \( \alpha^{\prime} \) :

-

Significance level in statistical tests

References

Arora J (2004) Introduction to optimum design. Academic Press, San Diego. https://doi.org/10.1016/B978-012064155-0/50001-X

Barroso ES, Parente E, Cartaxo de Melo AM (2017) A hybrid PSO-GA algorithm for optimization of laminated composites. Struct Multidiscip Optimiz 55:2111–2130. https://doi.org/10.1007/s00158-016-1631-y

Belegundu AD, Arora JS (1985) A study of mathematical programming methods for structural optimization. Part I: theory. Int J Numer Meth Eng 21:1583–1599. https://doi.org/10.1002/nme.1620210904

Berry A, Vamplew P (2004) PoD can mutate: a simple dynamic directed mutation approach for genetic algorithms. In: The 2nd international conference on artificial intelligence in science and technology (AISAT 2004). pp 200–205

Canayaz M, Karci A (2016) Cricket behaviour-based evolutionary computation technique in solving engineering optimization problems. Appl Intell 44:362–376. https://doi.org/10.1007/s10489-015-0706-6

Cao H, Qian X, Zhou Y (2018) Large-scale structural optimization using metaheuristic algorithms with elitism and a filter strategy. Struct Multidiscip Optim 57:799–814. https://doi.org/10.1007/s00158-017-1784-3

Chen S-y, Shui X-f, Huang H (2017) Improved genetic algorithm with two-level approximation using shape sensitivities for truss layout optimization. Struct Multidiscip Optim 55:1365–1382. https://doi.org/10.1007/s00158-016-1583-2

Coello CAC (2000) Use of a self-adaptive penalty approach for engineering optimization problems. Comput Ind 41:113–127. https://doi.org/10.1016/S0166-3615(99)00046-9

Coello Coello CA (2000) Constraint-handling using an evolutionary multiobjective optimization technique. Civil Eng Syst 17:319–346. https://doi.org/10.1080/02630250008970288

Coello CAC, Montes EM (2002) Constraint-handling in genetic algorithms through the use of dominance-based tournament selection. Adv Eng Inform 16:193–200. https://doi.org/10.1016/S1474-0346(02)00011-3

Corbera Caraballo S, Olazagoitia Rodríguez JL, Lozano Ruiz JA, Álvarez Fernández R (2017) Optimization of a butterfly valve disc using 3D topology and genetic algorithms. Struct Multidiscip Optim 56:941–957. https://doi.org/10.1007/s00158-017-1694-4

Cuevas E, Cienfuegos M (2014) A new algorithm inspired in the behavior of the social-spider for constrained optimization. Expert Syst Appl 41:412–425. https://doi.org/10.1016/j.eswa.2013.07.067

Das AK, Pratihar DK (2017) A direction-based exponential crossover operator for real-coded genetic algorithm. Paper presented at the seventh international conference on theoretical, applied, computational and experimental mechanics (ICTACEM 2017), IIT Kharagpur, India

Das AK, Pratihar DK (2018) Performance improvement of a genetic algorithm using a novel restart strategy with elitism principle. Int J Hybrid Intell Syst (pre-press): 1–15. https://doi.org/10.3233/his-180257

Das AK, Pratihar DK (2019) A directional crossover (DX) operator for real parameter optmization using genetic algorithm. Appl Intell 49:1841. https://doi.org/10.1007/s10489-018-1364-2

Deb K (1991) Optimal design of a welded beam via genetic algorithms. AIAA J 29:2013–2015

Deb K (1997) GeneAS: A robust optimal design technique for mechanical component design. In: Dasgupta D, Michalewicz Z (eds) Evolutionary algorithms in engineering applications. Springer, Berlin, pp 497–514. https://doi.org/10.1007/978-3-662-03423-1_27

Deb K (2000) An efficient constraint handling method for genetic algorithms. Comput Methods Appl Mech Eng 186:311–338. https://doi.org/10.1016/S0045-7825(99)00389-8

Deb K (2001) Multi-objective optimization using evolutionary algorithms. Wiley, Chichester

Deb K, Beyer H-g (2001) Self-adaptive genetic algorithms with simulated binary crossover. Evol Comput 9:197–221. https://doi.org/10.1162/106365601750190406

Deb K, Goyal M (1996) A combined genetic adaptive search (GeneAS) for engineering design. Comput Sci Inf 26:30–45

Deep K, Thakur M (2007) A new mutation operator for real coded genetic algorithms. Appl Math Comput 193:211–230. https://doi.org/10.1016/j.amc.2007.03.046

Derrac J, García S, Molina D, Herrera F (2011) A practical tutorial on the use of nonparametric statistical tests as a methodology for comparing evolutionary and swarm intelligence algorithms. Swarm Evol Comput 1:3–18. https://doi.org/10.1016/j.swevo.2011.02.002

Derrac J, García S, Hui S, Suganthan PN, Herrera F (2014) Analyzing convergence performance of evolutionary algorithms: a statistical approach. Inf Sci 289:41–58. https://doi.org/10.1016/j.ins.2014.06.009

Elkhechafi M, Hachimi H, Elkettani Y (2018) A new hybrid cuckoo search and firefly optimization. Monte Carlo Methods Appl 24(1):71–77

Furuya H, Haftka RT (1995) Placing actuators on space structures by genetic algorithms and effectiveness indices. Struct Optim 9:69–75. https://doi.org/10.1007/bf01758822

García S, Fernández A, Luengo J, Herrera F (2010) Advanced nonparametric tests for multiple comparisons in the design of experiments in computational intelligence and data mining: experimental analysis of power. Inf Sci 180:2044–2064. https://doi.org/10.1016/j.ins.2009.12.010

Goldberg DE (1989) Genetic algorithms in search, optimization and machine learning. Addison-Wesley Longman Publishing Co., Inc, Boston

Gonçalves MS, Lopez RH, Miguel LFF (2015) Search group algorithm: a new metaheuristic method for the optimization of truss structures. Comput Struct 153:165–184. https://doi.org/10.1016/j.compstruc.2015.03.003

He Q, Wang L (2007) An effective co-evolutionary particle swarm optimization for constrained engineering design problems. Eng Appl Artif Intell 20:89–99. https://doi.org/10.1016/j.engappai.2006.03.003

Hinterding R (1995) Gaussian mutation and self-adaption for numeric genetic algorithms. In: Proceedings of international conference on evolutionary computation (ICEC 1995). pp 384–389. https://doi.org/10.1109/icec.1995.489178

Hinterding R, Michalewicz Z, Peachey TC (1996) Self-adaptive genetic algorithm for numeric functions. Parallel problem solving from nature—PPSN IV. Springer, Berlin, pp 420–429

Holland JH (1992) Adaptation in natural and artificial systems. An introductory analysis with application to biology, control, and artificial intelligence, 2nd edn. MIT Press, Cambridge

Huang F-z, Wang L, He Q (2007) An effective co-evolutionary differential evolution for constrained optimization. Appl Math Comput 186:340–356. https://doi.org/10.1016/j.amc.2006.07.105

Jafari M, Moussavian H, Chaleshtari MHB (2018) Optimum design of perforated orthotropic and laminated composite plates under in-plane loading by genetic algorithm. Struct Multidiscip Optim 57:341–357. https://doi.org/10.1007/s00158-017-1758-5

Jain N, Jain VK, Deb K (2007) Optimization of process parameters of mechanical type advanced machining processes using genetic algorithms. Int J Mach Tools Manuf 47:900–919. https://doi.org/10.1016/j.ijmachtools.2006.08.001

Kannan B, Kramer SN (1994) An augmented Lagrange multiplier based method for mixed integer discrete continuous optimization and its applications to mechanical design. J Mech Des 116:405–411. https://doi.org/10.1115/1.2919393

Kaveh A, Bakhshpoori T (2016) A new metaheuristic for continuous structural optimization: water evaporation optimization. Struct Multidiscip Optim 54:23–43. https://doi.org/10.1007/s00158-015-1396-8

Kaveh A, Talatahari S (2010) An improved ant colony optimization for constrained engineering design problems. Eng Comput 27:155–182. https://doi.org/10.1108/02644401011008577

Kazemzadeh Azad S (2017) Enhanced hybrid metaheuristic algorithms for optimal sizing of steel truss structures with numerous discrete variables. Struct Multidiscip Optim 55:2159–2180. https://doi.org/10.1007/s00158-016-1634-8

Kogiso N, Watson LT, Gürdal Z, Haftka RT (1994a) Genetic algorithms with local improvement for composite laminate design. Struct Optim 7:207–218. https://doi.org/10.1007/bf01743714

Kogiso N, Watson LT, GÜRdal Z, Haftka RT, Nagendra S (1994b) Design of composite laminates by a genetic algorithm with memory. Mech Compos Mater Struct 1:95–117. https://doi.org/10.1080/10759419408945823

Koh B-I, George AD, Haftka RT, Fregly BJ (2006) Parallel asynchronous particle swarm optimization. Int J Numer Meth Eng 67:578–595. https://doi.org/10.1002/nme.1646

Ku K, Rao S, Chen L (1998) Taguchi-aided search method for design optimization of engineering systems. Eng Optim 30:1–23. https://doi.org/10.1080/03052159808941235

Kuo H-C, Lin C-H (2013) A directed genetic algorithm for global optimization. Appl Math Comput 219:7348–7364. https://doi.org/10.1016/j.amc.2012.12.046

Le Riche R, Haftka RT (1995) Improved genetic algorithm for minimum thickness composite laminate design. Compos Eng 5:143–161. https://doi.org/10.1016/0961-9526(95)90710-S

Lee KS, Geem ZW (2005) A new meta-heuristic algorithm for continuous engineering optimization: harmony search theory and practice. Comput Methods Appl Mech Eng 194:3902–3933. https://doi.org/10.1016/j.cma.2004.09.007

Ling SH, Leung FHF (2007) An improved genetic algorithm with average-bound crossover and wavelet mutation operations. Soft Comput 11:7–31. https://doi.org/10.1007/s00500-006-0049-7

MacKay DJ, Mac Kay DJ (2003) Information theory, inference and learning algorithms. Cambridge University Press, Cambridge

Mahdavi M, Fesanghary M, Damangir E (2007) An improved harmony search algorithm for solving optimization problems. Appl Math Comput 188:1567–1579. https://doi.org/10.1016/j.amc.2006.11.033

Mäkinen RA, Périaux J, Toivanen J (1999) Multidisciplinary shape optimization in aerodynamics and electromagnetics using genetic algorithms. Int J Numer Meth Fluids 30:149–159. https://doi.org/10.1002/(SICI)1097-0363(19990530)30:2%3c149:AID-FLD829%3e3.0.CO;2-B

Mezura-Montes E, Coello CAC (2008) An empirical study about the usefulness of evolution strategies to solve constrained optimization problems. Int J Gen Syst 37:443–473. https://doi.org/10.1080/03081070701303470

Mezura-Montes E, Coello CC, Velázquez-Reyes J (2006) Increasing successful offspring and diversity in differential evolution for engineering design. In: Proceedings of the seventh international conference on adaptive computing in design and manufacture (ACDM 2006), pp 131–139

Michalewicz Z (1996) Genetic algorithms + data structures = evolution programs, 3rd edn. Springer, New York

Michalewicz Z, Schoenauer M (1996) Evolutionary algorithms for constrained parameter optimization problems. Evol Comput 4:1–32. https://doi.org/10.1162/evco.1996.4.1.1

Mirjalili S (2016) SCA: a sine cosine algorithm for solving optimization problems. Knowl-Based Syst 96:120–133. https://doi.org/10.1016/j.knosys.2015.12.022

Mirjalili S, Mirjalili SM, Lewis A (2014) Grey wolf optimizer. Adv Eng Softw 69:46–61. https://doi.org/10.1016/j.advengsoft.2013.12.007

Munteanu C, Lazarescu V (1999) Improving mutation capabilities in a real-coded genetic algorithm. In: Evoworkshops: evolutionary image analysis, signal processing and telecommunications. Berlin Heidelberg, pp 138–149

Nagendra S, Haftka R, Gurdal Z (1993) Design of a blade stiffened composite panel by genetic algorithm. In: 34th structures, structural dynamics and materials conference. La Jolla, CA, pp 2418–2436. https://doi.org/10.2514/6.1993-1584

Nagendra S, Jestin D, Gürdal Z, Haftka RT, Watson LT (1996) Improved genetic algorithm for the design of stiffened composite panels. Comput Struct 58:543–555. https://doi.org/10.1016/0045-7949(95)00160-I

Press WH, Teukolsky SA, Vetterling WT, Flannery BP (2007) Section 22.3, gray codes, numerical recipes: the art of scientific computing, 3rd edn. Cambridge University Press, New York

Ragsdell KM, Phillips DT (1976) Optimal design of a class of welded structures using geometric programming. J Eng Industry 98:1021–1025. https://doi.org/10.1115/1.3438995

Raj KH, Setia R (2017) Quantum seeded evolutionary computational technique for constrained optimization in engineering design and manufacturing. Struct Multidiscip Optim 55:751–766. https://doi.org/10.1007/s00158-016-1529-8

Ray T, Liew KM (2003) Society and civilization: an optimization algorithm based on the simulation of social behavior. IEEE Trans Evol Comput 7:386–396. https://doi.org/10.1109/TEVC.2003.814902

Sadollah A, Bahreininejad A, Eskandar H, Hamdi M (2013) Mine blast algorithm: a new population based algorithm for solving constrained engineering optimization problems. Appl Soft Comput 13:2592–2612. https://doi.org/10.1016/j.asoc.2012.11.026

Sandgren E (1990) Nonlinear integer and discrete programming in mechanical design optimization. J Mech Des 112:223–229. https://doi.org/10.1115/1.2912596

Saremi S, Mirjalili S, Lewis A (2017) Grasshopper optimisation algorithm: theory and application. Adv Eng Softw 105:30–47. https://doi.org/10.1016/j.advengsoft.2017.01.004

Schutte JF, Koh B, Reinbolt JA, Haftka RT, George AD, Fregly BJ (2005) Evaluation of a particle swarm algorithm for biomechanical optimization. J Biomech Eng 127:465–474

Schwefel HP (1987) Collective phenomena in evolutionary systems. Universität Dortmund, Abteilung Informatik

Sobieszczanski-Sobieski J, Haftka RT (1997) Multidisciplinary aerospace design optimization: survey of recent developments. Struct Optim 14:1–23. https://doi.org/10.1007/bf01197554

Soremekun G, Gürdal Z, Haftka RT, Watson LT (2001) Composite laminate design optimization by genetic algorithm with generalized elitist selection. Comput Struct 79:131–143. https://doi.org/10.1016/S0045-7949(00)00125-5

Tayal A, Singh SP (2017) Designing flexible stochastic dynamic layout: an integrated firefly and chaotic simulated annealing-based approach. Glob J Flex Syst Manag 18:89–98. https://doi.org/10.1007/s40171-016-0140-6

Tayal A, Singh SP (2018) Integrating big data analytic and hybrid firefly-chaotic simulated annealing approach for facility layout problem. Ann Oper Res 270(1–2):489–514

Temby L, Vamplew P, Berry A (2005) Accelerating real-valued genetic algorithms using mutation-with-momentum. In: Advances in artificial intelligence (AI 2005). Springer, Berlin, pp 1108–1111

Todoroki A, Haftka RT (1998) Stacking sequence optimization by a genetic algorithm with a new recessive gene like repair strategy. Compos B Eng 29:277–285. https://doi.org/10.1016/S1359-8368(97)00030-9

Van Den Bergh F, Engelbrecht AP (2006) A study of particle swarm optimization particle trajectories. Inf Sci 176:937–971. https://doi.org/10.1016/j.ins.2005.02.003

Venter G, Haftka RT (2009) Constrained particle swarm optimization using a bi-objective formulation. Struct Multidiscip Optim 40:65. https://doi.org/10.1007/s00158-009-0380-6

Wang L, Li L-p (2010) An effective differential evolution with level comparison for constrained engineering design. Struct Multidiscip Optim 41:947–963. https://doi.org/10.1007/s00158-009-0454-5

Wang Y, Cai Z, Zhou Y, Fan Z (2009) Constrained optimization based on hybrid evolutionary algorithm and adaptive constraint-handling technique. Struct Multidiscip Optim 37:395–413. https://doi.org/10.1007/s00158-008-0238-3

Wang Y, Zhao W, Zhou G, Gao Q, Wang C (2018) Optimization of an auxetic jounce bumper based on Gaussian process metamodel and series hybrid GA-SQP algorithm. Struct Multidiscip Optim 57:2515–2525. https://doi.org/10.1007/s00158-017-1869-z

Zhang M, Luo W, Wang X (2008) Differential evolution with dynamic stochastic selection for constrained optimization. Inf Sci 178:3043–3074. https://doi.org/10.1016/j.ins.2008.02.014

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Das, A.K., Pratihar, D.K. Solving engineering optimization problems using an improved real-coded genetic algorithm (IRGA) with directional mutation and crossover. Soft Comput 25, 5455–5481 (2021). https://doi.org/10.1007/s00500-020-05545-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-020-05545-9