Abstract

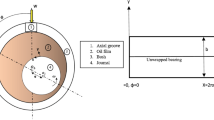

The purpose of this paper is to propose magnetorheological fluid-lubricated rubber stern bearing test ring, to study the effects of temperature, magnetic field strength and eccentricity ratio on lubrication performance. The Reynolds equation considering effects of eccentricity ratio, temperature and magnetic field strength is adopted and solved by finite difference method and successive over-relaxation method to calculate pressure distribution and friction coefficient with real bearing shapes and boundary conditions. Bearing capacity can be improved and friction coefficient can be reduced by decreasing temperature, increasing magnetic field strength and increasing eccentricity ratio. The paper’s results may provide important design theoretical and experimental guidelines support for rubber stern bearing in this kind of magnetorheological fluids-lubricated.

Similar content being viewed by others

References

Cruze D, Hemalatha G, Jebadurai SVS et al (2018) A review on the magnetorheological fluid, damper and its applications for seismic mitigation. Civ Eng J 4(12):3058–3074

Aruna MN, Rahman MR, Joladarashi S et al (2020) Investigation of sedimentation, rheological, and damping force characteristics of carbonyl iron magnetorheological fluid with/without additives. J Braz Soc Mech Sci Eng 42:228. https://doi.org/10.1007/s40430-020-02322-5

Rabinow J (1948) The magnetic fluid clutch. Electr Eng 67(12):1308–1315. https://doi.org/10.1109/EE.1948.6444497

Rabinow J (1951) Magnetic Fluid Torque and Force Transmitting Device. U.S. Patent, US78342647A, http://www.freepatentsonline.com/2575360.html

Milecki A, Hauke M (2012) Application of magnetorheological fluid in industrial shock absorbers. Mech Syst Signal Process 28:528–541. https://doi.org/10.1016/j.ymssp.2011.11.008

Lim ST, Choi HJ, Jhon MS (2005) Magnetorheological characterization of carbonyl iron-organoclay suspensions. IEEE Trans Magn 41(10):3745–3747. https://doi.org/10.1142/S0217979205029985

Jang IB, Kim HB, Lee JY, You JL, Choi HJ (2005) Role of organic coating on carbonyl iron suspended particles in magnetorheological fluids. J Appl Phys 97(10):24–27. https://doi.org/10.1063/1.1853835

Rodríguez-López J, Elvira MD ,Espinosa LF (2012) Magnetorheological fluid characterization using ultrasound measurements. In: IOP conference series: materials science and engineering, vol 42, no. 1, p 2032. https://doi.org/https://doi.org/10.1088/1757-899X/42/1/012032

Zhang X, Li W, Gong XL (2008) Study on magnetorheological shear thickening fluid. In: IOP conference series”, smart materials and structures, vol 17 no. 1, p. 015051. https://doi.org/10.1088/0964-1726/17/1/015051

Zite JL, Ahmadkhanlou F, Neelakantan VA ,Washington GN (2006) A magnetorheological fluid based orthopedic active knee brace. In: Proceedings of SPIE 6171, smart structures and materials 2006: industrial and commercial applications of smart structures technologies, 61710H. https://doi.org/10.1117/12.658693

Papell SS (1965) Low viscosity magnetic fluid obtained by the olloidal suspension of magnetic particles. US Patent 3,215,572.

McTague JP (1969) Magnetoviscosity of magnetic colloids. J Chem Phys 51:133. https://doi.org/10.1063/1.1671697

Odenbach S (2000) Magnetoviscous effects in ferrofluids. Appl. Heol. 10:178–184

Odenbach S (2004) Recent progress in magnetic fluid research. J Phys Condens Matter 16(32):1135–1150

Jacob R (1951) Magnetic fluid torque and force transmitting evice. US Patent 2,575,360.

Carlson JD, Chrzan MJ (1994) Magnetorheological fluid ampers. US Patent 5,277,281.

Huang J, Zhang JQ, Yang Y, Wei YQ (2002) Analysis and esign of a cylindrical magneto-rheological fluid brake. J Mater Process Technol 129:559–562. https://doi.org/10.1016/S0924-0136(02)00634-9

Baranwal D, Deshmukh TS (2012) MR-Fluid technology nd its application—a review. Int J Emerg Technol Adv Eng 2(12):563–569

Wang J, Meng G (2001) Magnetorheological fluid devices: principles, characteristics and applications in mechanical engineering. Proc Inst Mech Eng Part L J Mater Des Appl 215(3):165–174. https://doi.org/10.1243/1464420011545012

De Vicente J, Klingenberg D, Hidalgo-Alvarez R (2011) Magnetorheological fluids: a review. Soft Matter 7(8):3701–3710. https://doi.org/10.1039/c0sm01221a

Bahar A, Pozo F, Acho L, Rodellar J, Barbat A (2010) Parameter identification of large-scale magnetorheological dampers in a benchmark building. Comput. Struct. 8(3):198–206. https://doi.org/10.23919/ECC.2009.7074451

Sarkar C, Hirani H (2017) Experimental studies on magnetorheological brake containing plane, holed and slotted discs. Ind Lubr Tribol 69(2):116–122. https://doi.org/10.1108/ILT-12-2015-0205

Lijesh KP, Deepak K, Harish H (2017) Synthesis and field dependent shear stress evaluation of stable MR fluid for brake application. Ind Lubr Tribol 69(14):282–294. https://doi.org/10.1108/ILT-03-2016-0061

Liu C, Hu JA (2019) Magnetorheological hydrostatic guideway system for machining vibration control. J Braz Soc Mech Sci Eng 41:12. https://doi.org/10.1007/s40430-018-1525-6

Lv F, Jiao C, Zou D, Ta N, Zhushi R (2019) Analysis of misaligned water-lubricated polymer bearing with axial grooves. Ind Lubr Tribol 71(3):411–419. https://doi.org/10.1108/ILT-08-2018-0320

Zhao ZM, Zhang R (2020) Theoretical and experimental analysis of a water-lubricated rubber journal bearing with a large aspet ratio. Industrial Lubrication and Tribology, Vol. ahead-of-print No. ahead-of-print. https://doi.org/https://doi.org/10.1108/ILT-10-2019-0400

Hesselbach J, Abel-keilhack C (2003) Active hydrostatic bearing with magnetorheological fluid. J Appl Phys 93(10):8441–8443. https://doi.org/10.1063/1.1555850

Urreta H, Leicht Z, Sanchez A, Agirre A, Kuzhir P, Magnac G (2010) Hydrodynamic bearing lubricated with magnetic fluids. J Intell Mater Syst Struct 21(15):1491–1499. https://doi.org/10.1088/1742-6596/149/1/012113

Lampaert Stefan GE, van Ostayen RAJ (2020) Lubrication theory for Bingham plastics. Tribol Int 147:106–160. https://doi.org/10.1016/j.triboint.2020.106160

Abbaspur A, Norouzi M, Akbarzadeh P, Vaziri SA (2020) Analysis of nonlinear viscoelastic lubrication using Giesekus constitutive equation. Proc Inst Mech Eng Part J J Eng Tribol. https://doi.org/10.1177/1350650120944280

Tichy J (1991) Hydrodynamic lubrication theory for the Bingham plastic flow model. J Rheol 35(4):477–496. https://doi.org/10.1122/1.550231

Gertzos KP, Nikolakopoulos PG, Papadopoulos CA (2008) CFD analysis of journal bearing hydrodynamic lubrication by Bingham lubricant. Tribol Int 41(12):1190–1204. https://doi.org/10.1016/j.triboint.2008.03.002

Bompos DA, Nikolakopoulos PG (2016) Rotordynamicanalysis of a shaft using magnetorheological and nanomagne-torheological fluid journal bearings. Tribol Trans 59(1):108–118. https://doi.org/10.1080/10402004.2015.1050137

Babin A, Fetisov A, Tyurin V (2020) Numerical modelling of fluid-film bearing lubricated with magnetorheological fluid. In: Radionov A, Kravchenko O, Guzeev V, Rozhdestvenskiy Y (eds) Proceedings of the 5th international conference on industrial engineering (ICIE 2019). ICIE 2019. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-22041-9_136

Bhat AK; Vaz N; Kumar Y; Rolvin DS; Kumar P (2019) Comparative study of journal bearing performance with ferrofluid and MR fluid as lubricant. In: AIP conference proceedings, vol 2080, p. 040008. https://doi.org/10.1063/1.5092926

Rao BN, Sekhar AS (2019) Analysis of magneto rheological fluid journal bearing. Appl Mech Mater 895:152–157. https://doi.org/10.4028/www.scientific.net/amm.895.152

Kt S, Sharma SC (2019) A simulation study on the behavior of magnetorheological fluid on Herringbone-grooved hybrid slot-entry bearing. Tribol Trans 62(6):1099–1118. https://doi.org/10.1080/10402004.2019.1649775

Lampaert SGE, Quinci F, van Ostayen Ron AJ (2020) Rheological texture in a journal bearing with magnetorheological fluids. J Magn Magn Mater 499:166218. https://doi.org/10.1016/j.jmmm.2019.166218

Urreta H, Aguirre G, Kuzhir P, Lopez DL, Luis N (2019) Actively lubricated hybrid journal bearings based on magnetic fluids for high-precision spindles of machine tools. J Intell Mater Syst Struct 30(15):2257–2271. https://doi.org/10.1177/1045389X19862358

Sahu K, Sharma SC (2019) Magneto-rheological fluid slot-entry journal bearing considering thermal effects. J Intell Mater Syst Struct 30(18–19):2831–2852. https://doi.org/10.1177/1045389X19873401

Lampaert SGE, Van Ostayen RAJ (2019) Experimental results on a hydrostatic bearing lubricated with a magnetorheological fluid. Curr Appl Phys 19(12):1441–1448. https://doi.org/10.1016/j.cap.2019.09.004

Laukiavich C, Braun MJ, Chandy A (2014) A comparison between the performance of ferro-and magnetorheological fluids in a hydrodynamic bearing. Proc Inst Mech Eng Part J J Eng Tribol 228(6):649–666. https://doi.org/10.1177/1350650114523753

Genç S, Phulé Pradeep P (2002) Rheological properties of magnetorheological fluids. Smart Mater Struct 11(1):140. https://doi.org/10.1088/0964-1726/11/1/316

Su B, Huang L, Huang W, Wang X (2016) The load carrying capacity of textured sliding bearings with elastic deformation. Tribol Int 109:86–96. https://doi.org/10.1016/j.triboint.2016.11.030

Liu SB (2012) On boundary conditions in lubrication with one dimensional analytical solutions. Tribol Int 48:182–190. https://doi.org/10.1016/j.triboint.2011.11.021

Ai XL, Cheng HS, Zheng LQ (1993) A transient model for micro-elastohy dro dynamic lubrication with three-dimensional irregularities. ASME J Tribol 115:102–110. https://doi.org/10.1115/1.2920961

MIL-DTL-17901C(SH) (2005) Bearing components, bonded synthetic rubber, water lubricated. USA: department of defense. https://www.techstreet.com/standards/mil-mil-dtl-17901c?product_id=1442696. Accessed 7 Jan 2021

Acknowledgements

The authors give sincere thanks to the editors and the reviewers for their patient work and constructive suggestions. This work is supported by the Jiangxi Provincial Department of Science and Technology (No. 20192BBEL50028).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Daniel Onofre de Almeida Cruz.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, S., Long, Z. & Yang, X. Lubrication performance of magnetorheological fluid-lubricated rubber stern bearing test ring. J Braz. Soc. Mech. Sci. Eng. 43, 56 (2021). https://doi.org/10.1007/s40430-020-02796-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02796-3