Abstract

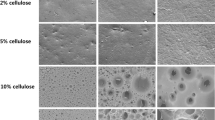

Polyvinylidene fluoride (PVDF) porous membranes were prepared by a two-step method of surface gelation-immersion precipitation phase inversion. The effects of spraying CS solution concentrations on the structure and properties of membranes were investigated. The results showed that with the concentration increasing of CS solution spraying on the surface of the casting solution film, the porosity of PVDF membranes gradually increased, the mean pore diameter of membranes firstly increased and then reduced, the surface contact angle decreased, and β crystal content in the top surface of membranes gradually decreased. The top surface of membrane without spraying CS solution displayed a dense structure, while the top surface of membranes after spraying CS solution exhibited a porous structure, while the cross-sectional structure of all membranes was composed of the finger-like voids. When the concentrations of spraying CS solution increased, the water flux of membranes firstly increased and then decreased.

Similar content being viewed by others

References

Kang GD, Cao YM (2014) Application and modification of poly(vinylidene fluoride) (PVDF) membranes-a review. J Membr Sci 463:145–165

Shen X, Yin XB, Zhao YP, Chen L (2015) Improved protein fouling resistance of PVDF membrane grafted with the polyampholyte layers. Colloid Polym Sci 293:1205–1213

Zhao XZ, Xuan HX, Chen YL, He CJ (2015) Preparation and characterization of superior antifouling PVDF membrane with extremely ordered and hydrophilic surface layer. J Membr Sci 494:48–56

Ma J, He Y, Zeng GY, Yang X, Chen X, Zhou L, Peng LY (2018) High-flux PVDF membrane incorporated with β-cyclodextrin modified halloysite nanotubes for dye rejection and Cu (II) removal from water. Polym Adv Technol 29:2704–2714

Zhao G, Chen WN (2015) Enhanced PVDF membrane performance via surface modification by functional polymer poly (N-isopropylacrylamide) to control protein adsorption and bacterial adhesion. React Funct Polym 97:19–29

Pan Y, Yu Z, Shi H, Chen Q, Zeng GY, Di HH, Ren XQ, He Y (2017) A novel antifouling and antibacterial surface-functionalized PVDF ultrafiltration membrane via binding Ag/SiO2 nanocomposites. J Chem Technol Biotechnol 92:562–572

Venaulta A, Chou YN, Wang YH, Hsu CH, Chou CJ, Bouyer D, Lee KR, Chang Y (2018) A combined polymerization and self-assembling process for the fouling mitigation of PVDF membranes. J Membr Sci 547:134–145

Sun CG, Feng XS (2017) Enhancing the performance of PVDF membranes by hydrophilic surface modification via amine treatment. Sep Purif Technol 185:94–102

Li GP, Shen LH, Luo YJ, Zhang SM (2014) The effect of silver-PAMAM dendrimer nanocomposites on the performance of PVDF membranes. Desalination 338:115–120

Chen FT, Shi XX, Chen B, Chen WX (2018) Preparation and characterization of amphiphilic copolymer PVDF-g-PMABS and its application in improving hydrophilicity and protein fouling resistance of PVDF membrane. Appl Surf Sci 427:787–797

Di MA, Sittinger M, Risbud MV (2005) Chitosan: a versatile biopolymer for orthopaedic tissue-engineering. Biomaterials 26:5983–5990

Han W, Liu CX, Bai RB (2007) A novel method to prepare high chitosan content blend hollow fiber membranes using a non-acidic dope solvent for highly enhanced adsorptive performance. J Membr Sci 302:150–159

Liao YZ, Xin MH, Li MC, Su S (2007) Preparation and characterization O-lauroyl chitosan/poly(L-lactic acid) blend membranes by solution-casting approach. Chin Chem Lett 18:213–216

Liao L, Fei F, Cheng BW, Meng J, Hu XY, Song J (2018) Fabrication and antibacterial properties of cellulose triacetate/chitosan reverse osmosis membrane. Acta Polym Sin 5:607–616

Xue YH, Fu RQ, Xu TW (2010) Preparation of SPEEK and SPEEK/chitosan composite proton exchange membranes for application indirect methanol full cells. Acta Polym Sin 3:285–191

Elizalde CNB, Al-Gharabli S, Kujaw J, Mavukkandy M, Hasan SW, Arafat HA (2018) Fabrication of blend polyvinylidene fluoride/chitosan membranes for enhanced flux and fouling resistance. Sep Purif Technol 190:68–76

Boributh S, Chanachai A, Jiraratananon R (2009) Modification of PVDF membrane by chitosan solution for reducing protein fouling. J Membr Sci 342:97–104

Al-Gharabli S, Al-Omari B, Kujawski W, Kujawa J (2020) Biomimetic hybrid membranes with covalently anchored chitosan – Material design, transport and separation. Desalination 491:114550–114567

Qin A, Li X, Zhao X, Liu D, He C (2015) Preparation and characterization of nano-chitin whisker reinforced PVDF membrane with excellent antifouling property. J Membr Sci 480:1–10

Li Q, Xu ZL, Yu LY (2010) Effects of mixed solvents and PVDF types on performances of PVDF microporous membranes. J Appl Polym Sci 115:2277–2287

Tao MM, Liu F, Ma BR, Xue LX (2013) Effect of solvent power on PVDF membrane polymorphism during phase inversion. Desalination 316:137–145

Chen P, Hou ZC, Lu XF (2011) FTIR characterization of PVDF powder grafted with N-vinylpyrrolidone(NVP) by simultaneous irradiation method. J Radiat Res Radiat Process 29(3):133–138

Ross GJ, Watts JF, Hill MP, Morrissey P (2000) Surface modification of poly(vinylidene fluoride) by alkaline treatment 1. The degradation mechanism. Polymer 41(5):1685–1696

Liang S, Xiao K, Mo Y, Huang X (2012) A novel ZnO nanoparticle blended polyvinylidene fluoride membrane for anti-irreversible fouling. J Membr Sci 394-395:184–192

Lang WZ, Xuan Z, Shen JP, Xu HP, Xu ZL, Guo YJ (2014) The contrastive study of chemical treatment on the properties of PVDF/PFSA and PVDF/PVP ultrafiltration membranes. Desalination 341:72–82

Smith B, Sridhar S, Khan AA (2006) Chitosan–poly(vinyl pyrrolidone) blends as membranes for direct methanol fuel cell applications. J Power Sources 159:846–854

Mathew ST, Abraham E (2008) Characterization of ferulic acid incorporated starch–chitosan blend films. Food Hydrocoll 22:826–835

Ma WZ, Cao YY, Gong FH, Liu CL, Tao GL, Wang XL (2015) Poly(vinylidene fluoride) membranes prepared via nonsolvent induced phase separation combined with the gelation. Colloids Surf A Physicochem Eng Asp 479:25–34

Xiao TH, Wang P, Yang X, Cai XH, Lu J (2015) Fabrication and characterization of novel asymmetric polyvinylidene fluoride (PVDF) membranes by the nonsolvent thermally induced phase separation(NTIPS) method for membrane distillation applications. J Membr Sci 489:160–174

Gregorio Jr R, Borges DS (2008) Effect of crystallization rate on the formation of the polymorphs of solution cast poly(vinylidene fluoride). Polymer 49:4009–4016

Ma W, Zhang J, Wang X (2007) Formation of poly(vinylidene fluoride) crystalline phases from tetrahydrofuran/N,N-dimethylformamide mixed solvent. J Mater Sci 43:398–401

Salimi A, Yousefi AA (2004) Conformational changes and phase transformation mechanisms in PVDF solution-cast membranes. J Polymer Sci, Part B: Polymer Phys 42:3487–3495

Zhao XJ, Cheng J, Chen SJ, Zhang J, Wang XL (2010) Controlled crystallization of poly(vinylidene fluoride) chains from mixed solvents composed of its good solvent and nonsolvent. J Polymer Sci, Part B: Polymer Phys 48:575–581

Zuo DY, Li HJ, Liu HT, Zhao SP (2012) Effect of different preparation methods on structure and properties of chitosan/poly-lactic acid blend porous membrane. J Porous Mater 19:1015–1022

Funding

This research was supported by the Local Science and Technology Development Project Guided by Hubei Provincial Central Committee (2018ZYYD058).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, C., Cheng, S., Li, H. et al. Effect of different concentrations of spraying chitosan solution on structure and properties of PVDF porous membrane. Colloid Polym Sci 299, 797–805 (2021). https://doi.org/10.1007/s00396-020-04793-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-020-04793-3