Abstract

Background

Two-phase anaerobic co-digestion (TAcoD) is a versatile technology for the simultaneous treatment of organic materials and biogas production. However, the produced digestate and supernatant of the system contain heavy metals and organic substances that need to be treated prior to discharge or land application. Therefore, in this study, an innovative TAcoD for organic fertilizer and high supernatant quality achievement was proposed.

Methods

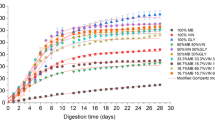

In the conventional TAcoD, mixed sewage sludge (SS) and food waste (FW) were first hydrolyzed in the acidogenic reactor, and then the hydrolyzate substrate was subjected to the methanogenic reactor (TAcoD 1). In the modified TAcoD (TAcoD 2), only FW was fed into the acidogenic reactor, and the produced hydrolyzed solid was directly converted to the organic fertilizer, while the supernatant with high soluble chemical demand (SCOD) concentration was further co-digested with SS in the methanogenic reactor.

Results

Although TAcoD 1 produced bio-methane yield and potential energy of 56.18% and 1.6-fold higher than TAcoD 2, the economical valorization of TAcoD 2 was 9-fold of that from TAcoD 1. The supernatant quality of TAcoD 2 was far better than TAcoD 1, since the SCOD, total nitrogen (TN), and total phosphor (TP) removal in TAcoD 2 and TAcoD 1 were 94.3%, 79.4%, 90.7%, and 68.9%, 28%, 46%, respectively. In terms of solid waste management, the modified TAcoD converted FW to organic fertilizer and achieved a solid reduction of 43.62% higher than that of conventional TAcoD.

Conclusions

This new modification in two-phase anaerobic co-digestion of food waste and sewage sludge provides a potentially feasible practice for simultaneous bio-methane, organic fertilizer, and high supernatant quality achievement.

Graphical abstract

Similar content being viewed by others

References

He J, Wang X, Yin XB, Li Q, Li X, Zhang YF, et al. Insights into biomethane production and microbial community succession during semi-continuous anaerobic digestion of waste cooking oil under different organic loading rates. AMB Express. 2018;8(1):92.

Lo IM, Woon KS. Food waste collection and recycling for value-added products: potential applications and challenges in Hong Kong. Environ Sci Pollut Res Int. 2016;23(8):7081–91.

Zhang M, Gao M, Yue S, Zheng T, Gao Z, Ma X, et al. Global trends and future prospects of food waste research: a bibliometric analysis. Environ Sci Pollut Res Int. 2018;25(25):24600–10.

European Communities. Preparatory Study on Food Waste. Across Eu. 201;27, October. URR: http://ec.europa.eu/environment/eussd/pdf/bio_foodwaste_report.pdf. Accessed on 5/15/2017.

Posmanik R, Labatut R, Kim A, Usack J, Tester J, Angenent L. Coupling hydrothermal liquefaction and anaerobic digestion for energy valorization from model biomass feedstocks. Bioresour Technol. 2017;233:134–43.

USEPA 2016. Advancing sustainable materials management: 2014 fact sheet. United States Environ. Prot. Agency, Off. L. Emerg. Manag. Washington, DC 20460 22.

Girotto F, Alibardi L, Cossu R. Food waste generation and industrial uses: a review. Waste Manag. 2015;45:32–41.

Kiran EU, Trzcinski AP, Ng WJ, Liu Y. Bioconversion of food waste to energy: a review. Fuel. 2014;134:389–99.

Neumann P, Pesante S, Venegas M, Vidal G. Developments in pre-treatment methods to improve anaerobic digestion of sewage sludge. Rev Environ Sci Biotechnol. 2016;15:173–211.

Pilli S, Yan S, Tyagi RD, Surampalli RY. Thermal pretreatment of sewage sludge to enhance anaerobic digestion: a review. Crit Rev Environ Sci Technol. 2015;45:669–702.

Ratanatamskul C, Wattanayommanaporn O, Yamamoto K. An on-site prototype two-stage anaerobic digester for co-digestion of food waste and sewage sludge for biogas production from high-rise building. Int Biodeterior Biodegradation. 2015;102:143–8.

Tuyet NT, Dan NP, Vu NC, Trung NLH, Thanh BX, De Wever H, et al. Laboratory-scale membrane up-concentration and co-anaerobic digestion for energy recovery from sewage and kitchen waste. Water Sci Technol. 2016;73:597–606.

Senturk E, Mahir I, Engin GO. The effect of shock loading on the performance of a thermophilic anaerobic contact reactor at constant organic loading rate. J Environ Health Sci Eng. 2015;12(1):84.

Park JG, Lee B, Jo SY, Lee JS, Jun HB. Control of accumulated volatile fatty acids by recycling nitrified effluent. J Environ Health Sci Eng. 2018;16(1):19–25. https://doi.org/10.1007/s40201-018-0291-9.

Babaei A, Shayegan J. Effects of temperature and mixing modes on the performance of municipal solid waste anaerobic slurry digester. J Environ Health Sci Eng. 2019;17(2):1077–84. https://doi.org/10.1007/s40201-019-00422-6.

Babaee A, Shayegan J, Roshani A. Anaerobic slurry co-digestion of poultry manure and straw: effect of organic loading and temperature. J Environ Health Sci Eng. 2013;11(1):15.

Chen S, Li N, Dong B, Zhao W, Dai L, Dai X. New insights into the enhanced performance of high solid anaerobic digestion with dewatered sludge by thermal hydrolysis: organic matter degradation and methanogenic pathways. J Hazard Mater. 2018;342:1–9.

Gupta D, Mahajani SM, Garg A. Effect of hydrothermal carbonization as pretreatment on energy recovery from food and paper wastes. Bioresour Technol. 2019;285:121329.

Mehariya S, Patel AK, Obulisamy PK, Punniyakotti E, Wong JWC. Co-digestion of food waste and sewage sludge for methane production: current status and perspective. Bioresour Technol. 2018;265:519–31. https://doi.org/10.1016/j.biortech.2018.04.030.

Hagos K, Zong J, Li D, Liu C, Lu X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew Sust Energ Rev. 2017;76:1485–96. https://doi.org/10.1016/j.rser.2016.11.184.

Srisowmeya G, Chakravarthy M, Nandhini DG. Critical considerations in two-stage anaerobic digestion of food waste – a review. Renew Sustain Energy Rev. 2020;119:109587. https://doi.org/10.1016/j.rser.2019.109587.

Bardi MJ, Rad HA. Simultaneous synergistic effects of addition of agro-based adsorbent on anaerobic co-digestion of food waste and sewage sludge. J Mater Cycles Waste Manage. 2019;22:65–79. https://doi.org/10.1007/s10163-019-00911-8.

Chiu SLH, Lo IMC. Reviewing the anaerobic digestion and co-digestion process of food waste from the perspectives on biogas production performance and environmental impacts. Environ Sci Pollut Res. 2016;23(24):24435–50.

Li W, Loh KC, Zhang J, Tong YW, Dai Y. Two-stage anaerobic digestion of food waste and horticultural waste in high-solid system. Appl Energy. 2018;209:400–8.

Wang F, Li WY, Yi XN. Two-phase anaerobic co-digestion of food waste and sewage sludge. Water Sci Technol. 2015;71(1):52–8.

Ariunbaatar J, Scotto Di Perta E, Panico A, Frunzo L, Esposito G, Lens PN, et al. Effect of ammoniacal nitrogen on one-stage and two-stage anaerobic digestion of food waste. Waste Manag. 2015;38:388–98.

Yang YQ, Shen DS, Li N, Xu D, Long YY, Lu XY. Co-digestion of kitchen waste and fruit-vegetable waste by two-phase anaerobic digestion. Environ Sci Pollut Res Int. 2013;20(4):2162–71.

Baldi F, Pecorini I, Iannelli R. Comparison of single-stage and two-stage anaerobic co-digestion of food waste and activated sludge for hydrogen and methane production. Renew Energy. 2019;143:1755–65. https://doi.org/10.1016/j.renene.2019.05.122.

Yin Y, Liu Y, Meng S, Kiran EU, Liu Y. Enzymatic pretreatment of activated sludge, food waste and their mixture for enhanced bioenergy recovery and waste volume reduction via anaerobic digestion. Appl Energy. 2016;179:1131–7.

Musa MA, Idrus S, Hasfalina CM, Daud NNN. Effect of organic loading rate on anaerobic digestion performance of mesophilic (UASB) reactor using cattle slaughterhouse wastewater as substrate. Int J Environ Res Public Health. 2018;15(10).

Liu GJ, Zheng D, Deng LW, Wen Q, Liu Y. Comparison of constructed wetland and stabilization pond for the treatment of digested effluent of swine wastewater. Environ Technol. 2014;35:2660–9.

Wen S, Liu H, He H, Luo L, Li X, Zeng G, et al. Treatment of anaerobically digested swine wastewater by Rhodobacter blasticus and Rhodobacter capsulatus. Bioresour Technol. 2016;222:33–8.

Mulbry W, Kondrad S, Pizarro C, Kebede-Westhead E. Treatment of dairy manure effluent using freshwater algae: algal productivity and recovery of manure nutrients using pilot-scale algal turf scrubbers. Bioresour Technol. 2008;99(17):8137–42.

Yang Y, Zhan Y, Li Y, Zhao H, Peng H. Nitrogen removal during anaerobic digestion of wasted activated sludge under supplementing Fe(III) compounds. Chem Eng J. 2018;332:711–6. https://doi.org/10.1016/j.cej.2017.09.133.

Maragkaki AE, Fountoulakis M, Gypakis A, Kyriakou A, Lasaridi K, Manios T. Pilot-scale anaerobic co-digestion of sewage sludge with agro-industrial by-products for increased biogas production of existing digesters at wastewater treatment plants. Waste Manag. 2017;59:362–70. https://doi.org/10.1016/j.wasman.2016.10.043.

Antonini S, Paris S, Eichert T, Clemens J. Nitrogen and phosphorus recovery from human urine by struvite precipitationand air stripping in Vietnam. Clean-Soil Air Water. 2011;39:1099–104.

Munir MT, Li B, Boiarkina I, Baroutian S, Yu W, Young BR. Phosphate recovery from hydrothermally treated sewage sludge using struvite precipitation. Bioresour Technol. 2017;239:171–9. https://doi.org/10.1016/j.biortech.2017.04.129.

Wang W, Ren X, Yang K, Hu Z, Yuan S. Inhibition of ammonia on anaerobic digestion of synthetic coal gasification wastewater and recovery using struvite precipitation. J Hazard Mater. 2017;340:152–9. https://doi.org/10.1016/j.jhazmat.2017.07.002.

Chiumenti A, da Borso F, Chiumenti R, Teri F, Segantin P. Treatment of digestate from a co-digestion biogas plant by means of vacuum evaporation: tests for process optimization and environmental sustainability. Waste Manag. 2013;33:1339–44.

Yan Z, Yang H, Qu F, Zhang H, Rong H, Yu H, et al. Application of membrane distillation to anaerobic digestion effluent treatment: identifying culprits of membrane fouling and scaling. Sci Total Environ. 2019;688:880–9.

Ek M, Bergström R, Bjurhem JE, Björlenius B, Hellström D. Concentration of nutrients from urine and reject water from anaerobically digested sludge. Water Sci Technol. 2006;54:437–44. https://doi.org/10.2166/wst.2006.924.

Ledda C, Schievano A, Salati S, Adani F. Nitrogen and water recovery from animal slurries by a new integrated ultrafiltration, reverse osmosis and cold stripping process: a case study. Water Res. 2013;47:6165–6.

Shi L, Ma B, Li X, Zhang Q, Peng Y. Advanced nitrogen removal without addition of external carbon source in an anaerobic/aerobic/anoxic sequencing batch reactor. Bioprocess Biosyst Eng. 2019;42(9):1507–15. https://doi.org/10.1007/s00449-019-02148-z.

Liu S, Daigger GT, Liu B, Zhao W, Liu J. Enhanced performance of simultaneous carbon, nitrogen and phosphorus removal from municipal wastewater in an anaerobic-aerobic-anoxic sequencing batch reactor (AOA-SBR) system by alternating the cycle times. Bioresour Technol. 2020;301:122750. https://doi.org/10.1016/j.biortech.2020.122750.

Bashar R, Gungor K, Karthikeyan KG, Barak P. Cost effectiveness of phosphorus removal processes in municipal wastewater treatment. Chemosphere. 2018;197:280–90. https://doi.org/10.1016/j.chemosphere.2017.12.169.

Yan Z, Liu K, Yu H, Liang H, Xie B, Li G, et al. Treatment of anaerobic digestion effluent using membrane distillation: effects of feed acidification on pollutant removal, nutrient concentration and membrane fouling. Desalination. 2019;449:6–15. https://doi.org/10.1016/j.desal.2018.10.011.

Federation Water Environment Standard Methods for the Examination of Water and Wastewater. 1999; 643.

Chinese National Standard (GB/T 8572–2010). Determination of Total Nitrogen Content for Compound Fertilizers Titrimetric Method after Distillation. The State Standard of the People's Republic of China Chinese National Standard. 2010a.

Chinese National Standard (GB/T17767.2–2010) Determination of Organic-Inorganic Compound Fertilizers—Part 2: Total Phosphorus Content. The State Standard of the People's Republic of China Chinese National Standard. 2010b.

Feng J, Zhang J, Zhang J, He Y, Zhang R, Chen C, et al. Enhanced methane production of vinegar residue by response surface methodology (RSM). AMB Express. 2017;7(1):89.

Yan H, Zhao C, Zhang J, Zhang R, Xue C, Liu G, et al. Study on biomethane production and biodegradability of different leafy vegetables in anaerobic digestion. AMB Express. 2017;7(1):27.

Gupta R, Basile A, Veziroglu TN. Compendium of hydrogen energy: hydrogen storage. Woodhead Publishing, Distribution and Infrastructure. 2015.

McCarty PL, Bae J, Kim J. Domestic wastewater treatment as a net energy producer–can this be achieved? ACS Publications; 2011.

Mata-Alvarez J, Mace S, Llabres P. Anaerobic digestion of organic solid wastes. Overv Res Achiev Perspect Bioresour Technol. 2000;74:3–16.

Astals S, Ariso M, Galí A, Mata-Alvarez J. Co-digestion of pig manure and glycerine: experimental and modelling study. J Environ Manag. 2011;92:1091–6.

Mata-Alvarez J, Dosta J, Mace S, Astals S. Codigestion of solid wastes: a review of its uses and perspectives including modeling. Crit Rev Biotechnol. 2011;31:99–111.

Mata-Alvarez J, Dosta J, Romero-Gueiza MS, Fonoll X, Peces M, Astals S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew Sust Energ Rev. 2014;36:412–27.

Astals S, Batstone DJ, Mata-Alvarez J, Jensen PD. Identification of synergistic impacts during anaerobic co-digestion of organic wastes. Bioresour Technol. 2014;169:421–7.

Shah FA, Mahmood Q, Rashid N, Pervez A, Raja IA, Shah MM. Co-digestion, pretreatment and digester design for enhanced methanogenesis. Renew Sust Energ Rev. 2015;42:627–42.

Holm-Nielsen JB, Al Seadi T, Oleskowicz-Popiel P. The future of anaerobic digestion and biogas utilization. Bioresour Technol. 2009;100:5478–84.

Jagadabhi PS, Lehtomaki A, Rintala J. Co-digestion of grass silage and cow manure in a cstr by re-circulation of alkali treated solids of the digestate. Environ Technol. 2008;29:1085–93.

Zhao T, Chen Y, Yu Q, Shi D, Chai H, Li L, et al. Enhancement of performance and stability of anaerobic co-digestion of waste activated sludge and kitchen waste by using bentonite. PLoS One. 2019;14(7):e0218856. https://doi.org/10.1371/journal.pone.0218856.

Mao C, Zhang T, Wang X, Feng Y, Ren G, Yang G. Process performance and methane production optimizing of anaerobic co-digestion of swine manure and corn straw. Sci Rep. 2017;7(1):9379. https://doi.org/10.1038/s41598-017-09977-6.

Xiao B, Qin Y, Zhang W, Wu J, Qiang H, Liu J. Temperature-phased anaerobic digestion of food waste: a comparison with single-stage digestions based on performance and energy balance. Bioresour Technol. 2018;249:826–34.

Xiao B, Zhang W, Yi H, Qin Y, Wu J, Liu J. Biogas production by two-stage thermophilic anaerobic co-digestion of food waste and paper waste: effect of paper waste ratio. Renew Energy. 2019;132:1301–9.

Wu C, Huang Q, Yu M, Ren Y, Wang Q, Sakai K. Effects of digestate recirculation on a two-stage anaerobic digestion system, particularly focusing on metabolite correlation analysis. Bioresour Technol. 2018. https://doi.org/10.1016/j.biortech.2017.12.020.

Gaby JC, Zamanzadeh M, Horn SJ. The effect of temperature and retention time on methane production and microbial community composition in staged anaerobic digesters fed with food waste. Biotechnol Biofuels. 2017. https://doi.org/10.1186/s13068-017-0989-4.

Paudel S, Kang Y, Yoo YS, Seo GT. Effect of volumetric organic loading rate (OLR) on H2and CH4 production by two-stage anaerobic co-digestion of food waste and brown water. Waste Manag. 2017;61:484–93.

Lin J, Zuo J, Gan L, Li P, Liu F, Wang K, et al. Effects of mixture ratio on anaerobic co-digestion with fruit and vegetable waste and food waste of China. J Environ Sci. 2011;23(8):1403–8.

Bardi MJ, Aminirad H. Synergistic effects of co-trace elements on anaerobic co-digestion of food waste and sewage sludge at high organic load. Environ Sci Pollut Res. 2020;27:18129–44. https://doi.org/10.1007/s11356-020-08252-y.

Kong X, Yu S, Xu S, Fang W, Liu J, Li H. Effect of Fe addition on volatile fatty acids evolution on anaerobic digestion at high organic loading rates. Waste Manag. 2018;71:719–27.

Chinese National Standard (GB8172–87). Control Standards for Urban Wastes for Agriculture Use. The State Standard of the People’s Republic of China Chinese National Standard. 1987.

Chinese National Standard (GB18877–2009). Organic-Inorganic Compound Fertilizer. The State Standard of the People’s Republic of China Chinese National Standard. 2009.

Tian Y, Liu SJ, Ma L, Wang YL, Chen GM. Review of heavy metals testing of bio-fertilizer. Chin Agric Sci Bull. 2011;27:16–21.

Roemer W, Samie IF. Iron-rich sewage sludge is not suitable for phosphorus recycling in agriculture. Wasser und Boden. 2002;54(6):28–32.

Mousavi SM, Bahmanyar MA, Pirdashti H, Moradi S. Nutritional (Fe, Mn, Ni, and Cr) and growth responses of rice plant affected by perennial application of two bio-solids. Environ Monit Assess. 2017;189(7):340.

Rout GR, Sahoo S. Role of Iron in plant growth and metabolism. Rev Agric Sci. 2015;3(0):1–24. https://doi.org/10.7831/ras.3.1.

Aller AJ, Bernal JL, Nozal M, Deban L. Effects of selected trace elements on plant growth. J Sci Food Agric. 1990;51:447–79.

Malamis S, Katsou E, Di Fabio S, Bolzonella D, Fatone F. Biological nutrients removal from the supernatant originating from the anaerobic digestion of the organic fraction of municipal solid waste. Crit Rev Biotechnol. 2014;34(3):244–57.

European Commission, 1998. Commission directive 98/15/EC of 27 February 1998. Off. J. Eur. Communities L 67/30, 41.

Gao D, Peng Y, Liang H. Study on nitrification and denitrification via nitrite accumulation under different operating conditions. J Biotechnol. 2008;136:667.

Donsì F, Ferrari G, Lenza E, Maresca P. Main factors regulating microbial inactivation by high-pressure homogenization: operating parameters and scale of operation. Chem Eng Sci. 2009;64:520e532.

Yang S, Yang F, Fu Z, Wang T, Lei R. Simultaneous nitrogen and phosphorus removal by a novel sequencing batch moving bed membrane bioreactor for wastewater treatment. J Hazard Mater. 2010;175:551e557.

Guadie A, Xia S, Zhang Z, Guo W, Ngo HH, Hermanowicz SW. Simultaneous removal of phosphorus and nitrogen from sewage using a novel combo system of fluidized bed reactor-membrane bioreactor (FBR-MBR). Bioresour Technol. 2013;149:276e285.

Jin L, Zhang G, Tian H. Current state of sewage treatment in China. Water Res. 2014;66:85e98.

Wu D, Ekama GA, Wang HG, Wei L, Lu H, Chui HK, et al. Simultaneous nitrogen and phosphorus removal in the sulfur cycle-associated enhanced biological phosphorus removal (EBPR) process. Water Res. 2014;49:251e264.

Lin H, Gan J, Rajendran A, Reis CER, Hu B. Phosphorus removal and recovery from digestate after biogas production. In: Biofuels—Status and Perspective InTech 2015.

Egle L, Rechberger H, Zessner M. Overview and description of technologies for recovering phosphorus from municipal wastewater. Resour Conserv Recycl. 2015;105:325–46.

Thomas EA. Phosphate removal by recirculating iron sludge. J Water Pollut Cont Fede. 1972:176–82.

Zheng W, Li X, Wang D, Yang Q, Luo K, Jing Y, et al. Remove and recover phosphorus during anaerobic digestion of excess sludge by adding waste iron scrap. J Serb Chem Soc. 2013;78(2):303–12. https://doi.org/10.2298/jsc120205057z.

World Bank (2010), World development indicators 2010, The world Bank, Washington, DC, available at: www.worldbank.org

Ma Y, Liu Y. Turning food waste to energy and resources towards a great environmental and economic sustainability: An innovative integrated biological approach. Biotechnol Adv. 2019;37(7). https://doi.org/10.1016/j.biotechadv.2019.06.013.

Lin W, Lin M, Zhou H, Wu H, Li Z, Lin W. The effects of chemical and bio-fertilizer usage on rhizosphere soil in tea orchards. PLoS One. 2019;14(5). https://doi.org/10.1371/journal.pone.0217018.

Ning C, Gao PD, Wang B, Lin W, Jiang N, Cai K. Impacts of chemical fertilizer reduction and organic amendments supplementation on soil nutrient, enzyme activity and heavy metal content. J Integr Agric. 2017;16(8):1819–31. https://doi.org/10.1016/s2095-3119(16)61476-4.

Chojnacka K, Moustakas K, Witek-Krowiak A. Bio-based fertilizers: a practical approach towards circular economy. Bioresour Technol. 2020;295:122223.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 13 kb)

Rights and permissions

About this article

Cite this article

Aminzadeh, M., Bardi, M.J. & Aminirad, H. A new approach to enhance the conventional two-phase anaerobic co-digestion of food waste and sewage sludge. J Environ Health Sci Engineer 19, 295–306 (2021). https://doi.org/10.1007/s40201-020-00603-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40201-020-00603-8