Abstract

In this work, the lamellar structural evolution and microvoids variations of β polypropylene (β-PP) during the processing of two different stretching methods, sequential biaxial stretching and simultaneous biaxial stretching, were investigated in detail. It was found that different stretching methods led to significantly different lamellae deformation modes, and the microporous membranes obtained from the simultaneous biaxial stretching exhibited better mechanical properties. For the sequential biaxial stretching, abundant coarse fibers originated from the tight accumulation of the lamellae parallel to the longitudinal stretching direction, whereas the lamellae perpendicular to the stretching direction were easily deformed and separated. Those coarse fibers were difficult to be separated to form micropores during the subsequent transverse stretching process, resulting in a poor micropores distribution. However, for the simultaneous biaxial stretching, the β crystal had the same deformation mode, that is, the lamellae distributed in different directions were all destroyed, forming abundant microvoids and little coarse fibers.

Similar content being viewed by others

References

Costa, C. M.; Lee, Y. H.; Kim, J. H.; Lee, S. Y.; Lanceros-Méndez, S. Recent advances on separator membranes for lithium-ion battery applications: from porous membranes to solid electrolytes. Energy Storage Mater. 2019, 22, 346–375.

Li, Y.; Pan, G.; Wang, J.; Zhang, Y.; Shi, H.; Yu, H.; Liu, Y. Tailoring the polyamide active layer of thin-film composite forward osmosis membranes with combined cosolvents during interfacial polymerization. Ind. Eng. Chem. Res. 2020, 59, 8230–8242.

Pan, L.; Wang, H.; Wu, C.; Liao, C.; Li, L. Tannic-acid-coated polypropylene membrane as a separator for lithium-ion batteries. ACS Appl. Mater. Interfaces 2015, 7, 16003–16010.

Park, S. H.; Kwon, S. J.; Shin, M. G.; Park, M. S.; Lee, J. S.; Park, C. H.; Park, H.; Lee, J. H. Polyethylene-supported high performance reverse osmosis membranes with enhanced mechanical and chemical durability. Desalination 2018, 436, 28–38.

Zhu, X.; Tang, X.; Luo, X.; Cheng, X.; Xu, D.; Gan, Z.; Wang, W.; Bai, L.; Li, G.; Liang, H. Toward enhancing the separation and antifouling performance of thin-film composite nanofiltration membranes: a novel carbonate-based preoccupation strategy. J. Colloid Interface Sci. 2020, 571, 155–165.

Lu, W.; Yuan, Z.; Zhao, Y.; Zhang, H.; Zhang, H.; Li, X. Porous membranes in secondary battery technologies. Chem. Soc. Rev. 2017, 46, 2199–2236.

Chu, F.; Kimura, Y. Structure and gas permeability of microporous films prepared by biaxial drawing of β-form polypropylene. Polymer 1996, 37, 573–579.

Luo, B.; Li, Z.; Zhang, J.; Wang, X. Formation of anisotropic microporous isotactic polypropylene (iPP) membrane via thermally induced phase separation. Desalination 2008, 233, 19–31.

Wu, T.; Xiang, M.; Cao, Y.; Kang, J.; Yang, F. Pore formation mechanism of β nucleated polypropylene stretched membranes. RSCAdv. 2014, 4, 36689–36701.

Wu, G. G.; Chen, W. B.; Ding, C.; Xu, L. Y.; Liu, Z. Y.; Yang, W.; Yang, M. B. Pore formation mechanism of oriented β polypropylene cast films during stretching and optimization of stretching methods: in situ SAXS and WAXD studies. Polyme 2019, 163, 86–95.

Li, J. X.; Cheung, W. L.; Chan, C. M. On deformation mechanisms of β-polypropylene 2. Changes of lamellar structure caused by tensile load. Polymer 1999, 40, 2089–2102.

Xu, R. J.; Chen, X. D.; Xie, J. Y.; Cai, Q.; Lei, C. H. Influence of melt-draw ratio on the crystalline structure and properties of polypropylene cast film and stretched microporous membrane. Ind. Eng. Chem. Res. 2015, 54, 2991–2999.

Zeng, F.; Xu, R.; Ye, L.; Xiong, B.; Kang, J.; Xiang, M.; Li, L.; Sheng, X.; Hao, Z. Effects of heat setting on the morphology and performance of polypropylene separator for lithium ion batteries. Ind. Eng. Chem. Res. 2019, 58, 2217–2224.

Lee, H.; Yanilmaz, M.; Toprakci, O.; Fu, K.; Zhang, X. A review of recent developments in membrane separators for rechargeable lithium-ion batteries. Energy Environ. Sci. 2014, 7, 3857–3886.

Wu, G. G.; Ding, C.; Chen, W. B.; Zhang, Y.; Yang, W.; Yang, M. B. Effect of the content of β form crystals on biaxially stretched polypropylene microporous membranes and the tuning of pore structures. Polymer 2019, 175, 177–185.

Zhang, D.; Ding, L.; Yang, F.; Lan, F.; Cao, Y.; Xiang, M. Effect of annealing on the microvoid formation and evolution during biaxial stretching of β nucleated isotactic polypropylene. Polymplast. Tech. Mater. 2020, 59, 1595–1607.

Zhang, C.; Liu, G.; Song, Y.; Zhao, Y.; Wang, D. Structural evolution of β-iPP during uniaxial stretching studied by in situ WAXS and SAXS. Polymer 2014, 55, 6915–6923.

Xiande, C.; Ruijie, X.; Jiayi, X.; Yuanfei, L.; Caihong, L.; Liangbin, L. The study of room-temperature stretching of annealed polypropylene cast film with row-nucleated crystalline structure. Polymer 2016, 94, 31–42.

Wu, G. G.; Xu, L. Y.; Chen, W. B.; Ding, C.; Liu, Z. Y.; Yang, W.; Yang, M. B. Oriented polypropylene cast films consisted of β-transcrystals induced by the nucleating agent self-assembly and its homogeneous membranes with high porosity. Polymer 2018, 151, 136–144.

Sadeghi, F.; Ajji, A.; Carreau, P. J. Analysis of microporous membranes obtained from polypropylene films by stretching. J. Membr. Sci. 2007, 292, 62–71.

Lyu, D.; Chen, R.; Lu, Y.; Men, Y. Subsequent but independent cavitation processes in isotactic polypropylene during stretching at small- and large-strain regimes. Ind. Eng. Chem. Res. 2018, 57, 8927–8937.

Lin, Y.; Chen, W.; Meng, L.; Wang, D.; Li, L. Recent advances in post-stretching processing of polymer films with in situ synchrotron radiation X-ray scattering. Soft Matter 2020, 16, 3599–3612.

Li, S.; Zheng, G.; Jia, Z.; Zhang, Z.; Liu, C.; Chen, J.; Li, Q.; Shen, C.; Peng, X. Effect of stretching on β -phase content of isotactic polypropylene melt containing β-nucleating agent. J. Macromol. Sci. B 2011, 51, 828–838.

Offord, G. T.; Armstrong, S. R.; Freeman, B. D.; Baer, E.; Hiltner, A.; Swinnea, J. S.; Paul, D. R. Porosity enhancement in β nucleated isotactic polypropylene stretched films by thermal annealing. Polymer 2013, 54, 2577–2589.

Wu, T.; Xiang, M.; Cao, Y.; Yang, F. Influence of annealing on stress-strain behaviors and performances of β nucleated polypropylene stretched membranes. J. Polym. Res. 2014, 21.

Yang, S.; Gu, J.; Yin, Y. A biaxial stretched β-isotactic polypropylene microporous membrane for lithium-ion batteries. J. Appl. Polym. Sci. 2018, 135, 45825.

Yang, F.; Wu, T.; Xiang, M.; Cao, Y. Deformation and pore formation mechanism of β nucleated polypropylene with different supermolecular structures. Eur. Polym. J. 2017, 91, 134–148.

Ding, L.; Ge, Q.; Xu, G.; Wu, T.; Yang, F.; Xiang, M. Influence of oriented β-lamellae on deformation and pore formation in β-nucleated polypropylene. J. Polym. Sci., Part B: Polym. Phys. 2017, 55, 1745–1759.

Zhu, Y.; Zhao, Y.; Fu, Q. Toward uniform pore-size distribution and high porosity of isotactic polypropylene microporous membrane by adding a small amount of ultrafine full-vulcanized powder rubber. Polymer 2016, 103, 405–414.

Bao, R.; Ding, Z.; Zhong, G.; Yang, W.; Xie, B.; Yang, M. Deformation-induced morphology evolution during uniaxial stretching of isotactic polypropylene: effect of temperature. Colloid Polym. Sci. 2012, 290, 261–274.

Bao, R. Y.; Ding, Z. T.; Liu, Z. Y.; Yang, W.; Xie, B. H.; Yang, M. B. Deformation-induced structure evolution of oriented β-polypropylene during uniaxial stretching. Polymer 2013, 54, 1259–1268.

Kurihara, H.; Kitade, S.; Ichino, K.; Akiba, I.; Sakurai, K. Elongation induced β- to α-crystalline transformation and microvoid formation in isotactic polypropylene as revealed by time-resolved WAXS/SAXS. Polym. J. 2018, 51, 199–209.

Chen, Q.; Wang, Z.; Zhang, S.; Cao, Y.; Chen, J. Structure evolution and deformation behavior of polyethylene film during biaxial stretching. ACS Omega 2020, 5, 655–666.

Jariyasakoolroj, P.; Tashiro, K.; Wang, H.; Yamamoto, H.; Chinsirikul, W.; Kerddonfag, N.; Chirachanchai, S. Isotropically small crystalline lamellae induced by high biaxial-stretching rate as a key microstructure for super-tough polylactide film. Polymer 2015, 68, 234–245.

Zhang, D.; Ding, L.; Yang, F.; Lan, F.; Cao, Y.; Xiang, M. Structural evolution of β-iPP with different supermolecular structures during the simultaneous biaxial stretching process. Polym. J. 2020, DOI: https://doi.org/10.1038/s41428-020-00430-6.

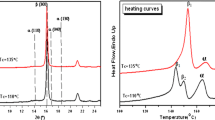

Chen, Z.; Kang, W.; Kang, J.; Chen, J.; Yang, F.; Cao, Y.; Xiang, M. Non-isothermal crystallization behavior and melting behavior of Ziegler-Natta isotactic polypropylene with different stereodefect distribution nucleated with bi-component β-nucleation agent. Polym. Bull. 2015, 72, 3283–3303.

Chen, X.; Lv, F.; Su, F.; Ji, Y.; Meng, L.; Wan, C.; Lin, Y.; Li, X.; Li, L. Deformation mechanism of iPP under uniaxial stretching over a wide temperature range: an in situ synchrotron radiation SAXS/WAXS study. Polymer 2017, 118, 12–21.

Bai, H.; Wang, Y.; Zhang, Z.; Han, L.; Li, Y.; Liu, L.; Zhou, Z.; Men, Y. Influence of annealing on microstructure and mechanical properties of isotactic polypropylene with β-phase nucleating agent. Macromolecules 2009, 42, 6647–6655.

Xiong, B.; Kang, J.; Chen, R.; Men, Y. Initiation of cavitation upon drawing of pre-oriented polypropylene film: in situ SAXS and WAXD studies. Polymer 2017, 128, 57–64.

Jones, A. T.; Aizlewood, J. M.; Beckett, D. R. Crystalline forms of isotactic polypropylene. Makromol. Chem. 1964, 75, 134–158.

Hermans, P. H.; Platzek, P. Beitrge zur Kenntnis des Deformationsmechanismus und der Feinstruktur der Hydratzellulose. Kolloid-Zeitschrift 1939, 88, 68–72.

Lu, X.; Li, X. Preparation of polyvinylidene fluoride membrane via a thermally induced phase separation using a mixed diluent. J. Appl. Polym. Sci. 2009, 114, 1213–1219.

Chen, Q.; Chen, D.; Kang, J.; Cao, Y.; Chen, J. Structure evolution of polyethylene in sequential biaxial stretching along the first tensile direction. Ind. Eng. Chem. Res. 2019, 58, 12419–12430.

Fischer, S.; Diesner, T.; Rieger, B.; Marti, O. Simulating and evaluating small-angle X-ray scattering of micro-voids in polypropylene during mechanical deformation. J. Appl. Crystallogr. 2010, 43, 603–610.

Thomas, C.; Ferreiro, V.; Coulon, G.; Seguela, R. In situ AFM investigation of crazing in polybutene spherulites under tensile drawing. Polymer 2007, 48, 6041–6048.

Sun, W.; Chen, T.; Chen, C.; Li, J. A study on membrane morphology by digital image processing. J. Membr. Sci. 2007, 305, 93–102.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51721091).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, DX., Ding, L., Yang, F. et al. Comparison of the Structural Evolution of β Polypropylene during the Sequential and Simultaneous Biaxial Stretching Process. Chin J Polym Sci 39, 620–631 (2021). https://doi.org/10.1007/s10118-021-2534-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-021-2534-y