Abstract

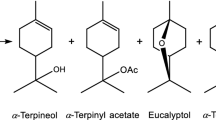

A new type of heterogeneous catalyst for hydration of α-pinene was prepared. Montmorillonite K10 was treated by various acids (H2SO4, HCl, HNO3, and ClCH2COOH) and successfully used for the mentioned reaction. The used characterization techniques showed that the acid treatment improved the properties of K10 important for the catalytic activity (SBET and acidity). On the other hand, the morphology and particle size distribution remained the same. Regarding the selectivity (side and consecutive reactions can proceed), the optimal reaction conditions were found (temperature, type of the catalyst, amount of the catalyst, molar ratio α-pinene: water, type of water, solvent). Using the optimal reaction conditions, 60% conversion of α-pinene was achieved with 45% selectivity to α-terpineol (80 °C, 25 wt% of K10/HCl, or K10/H2SO4, nα-pinene:nwater 1:7.5, 1,4-dioxane as a solvent, 24 h). Higher conversions of α-pinene, as well as higher selectivity to α-terpineol, were achieved using all acid treated K10 in comparison to raw K10. Considering the heterogeneous form of prepared catalysts, its availability, low price and easy method of preparation, these catalysts dispose of a large potential for application as catalysts for hydration reactions.

Graphic Abstract

Similar content being viewed by others

References

Sales A, de Oliveira FL, Bicas JL (2020) Curr. Opin. Food Sci. 37:98

Yadav MK, Patil MV, Jasra RV (2009) J. Mol. Catal. A: Chem. 297:101–109

Avila MC, Comelli NA, Firpo NH, Ponzi EN, Ponzi MI (2008) J. Chil. Chem. Soc. 53(1):1460–1462

Caovilla M, Caovilla A, Pergher SBC, Esmelindro MC, Fernandes C, Dariva C, Bernardo-Gausmao K, Oestreicher EG, Antunes OAC (2008) Catal. Today 133–135:695–698

Tai YN, Xu M, Ren JN, Dong M, Yang ZY, Pan SY, Fan GJ (2016) Sci. Food Agric. 96:954–961

Donaldson ME, Mestre VL, Vinci D, Liotta CL, Eckert CA (2009) Ind. Eng. Chem. Res. 48:2542–2547

Frija LMT, Afonso CAM (2012) Tetrahedron 68:7414–7421

Tsitsishvili V, Ivanova I, Ramishvili T, Kokiashvili N, Bukia T, Dobryakova I, Kurtsikidze G (2017) Bull. Georg. Natl. Acad. Sci. 11(3):79–87

Yahata K, Sakurai S, Hori S, Yoshioka S, Kaneko Y, Hasegawa K, Akai S (2020) Org. Lett. 22:1199–1203

Zukowska K, Paczek L, Grela K (2016) ChemCatChem 8:2817–2823

Comelli N, Avila MC, Volzone C, Ponzi M (2013) Cent. Eur. J. Chem. 11(5):689–697

Prakoso T, Hanley J, Soebianta MN, Soerawidjaja TH, Indarto A (2018) Catal. Lett. 148(2):725–731

Román-Aguirre M, De la Torre-Sáenz L, Flores WA, Robau-Sánchez A, Elguézabal AA (2005) Catal. Today 107:310–314

Pakdel H, Sarron S, Roy C (2001) J. Agric. Food Chem. 49(9):4337–4341

Robles-Dutenhefner PA, da Silva KAH, Siddiqui MR, Kozhevnikov IV, Gusevskaya EV (2001) J. Mol. Catal. A: Chem. 175(1):33–42

Ávila MC, Ponzi MI, Comelli NA (2015) J. Chromatogr. Sep. Tech. 6(7):1–6

Li L, Liu Y, Yu ST, Liu SW, Xie CX, Liu FS (2013) Res. Chem. Intermed. 41(4):2407–2414

Yuan B, Zhong H, Liu P, Xie C, Liu X, Yu F, Yu S, Zhang J (2016) Catal. Lett. 146(5):929–936

Liu SW, Yu ST, Liu FS, Xie CX, Li L, Ji KH (2008) J. Mol. Catal. A: Chem. 279(2):177–181

Vital J, Ramos AM, Silva IF, Valente H, Castanheiro JE (2000) Catal. Today 56(1–3):167–172

Yadav MK, Patil MV, Jasra RV (2009) J. Mol. Catal. A: Chem. 297(2):101–109

van der Waal JC, van Bekkum H, Vital JM (1996) J. Mol. Catal. A: Chem. 105:185–192

Mochida T, Ohnishi R, Horita N, Kamiya Y, Okuhara T (2007) Microporous Mesoporous Mater. 101(1):176–183

Wijayati N, Hidayah N, Mursiti S, Kusumastuti E (2018) IOP Conf. Ser.: Mater. Sci. Eng. 509:012093

Wijayati N, Pranowo HD, Jumina J, Triyono T (2011) Indones. J. Chem. 11(3):234–237

Yang G, Liu Y, Zhou Z, Zhang Z (2011) Chem. Eng. J. 168(1):351–358

Castanheiro JE, Ramos AM, Fonseca I, Vital J (2003) Catal. Today 82(1–4):187–193

Castanheiro JE, Fonseca IM, Ramos AM, Oliveira R, Vital J (2005) Catal. Today 104(2–4):296–304

Vyskočilová E, Gruberová A, Shamzhy M, Vrbková E, Krupka J, Červený L (2018) Reac. Kinet. Mech. Catal. 124(2):711–725

Baishya G, Sarmah B, Hazarika N (2013) Synlett 24(9):1137–1441

Kornatowski J, Baur WH, Pieper G, Rozwadowski M, Schmitz W, Cichowias A (1992) J. Chem. Soc. Faraday Trans. 88(9):1339–1343

R. P. Bell, Dissociation Constants. In Aqueous Solution (2020). https://www.britannica.com/science/acid-base-reaction/Dissociation-constants-in-aqueous-solution. Accessed 23 July 2020

Makarouni D, Lycourghiotis S, Kordouli E, Bourikas K, Kordulis C, Dourtoglou V (2018) Appl. Catal. B 224:740–750

Acknowledgements

This work was realized within the Operational Programme Prague – Competitiveness (CZ.2.16/3.1.00/24501) and “National Program of Sustainability” ((NPU I LO1613) MSMT-43760/2015). This work was also supported from the grant of Specific university research – grant No A2_FCHT_2020_008.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sekerová, L., Černá, H., Vyskočilová, E. et al. Preparation of α-Terpineol from Biomass Resource Catalysed by Acid Treated Montmorillonite K10. Catal Lett 151, 2673–2683 (2021). https://doi.org/10.1007/s10562-020-03514-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-020-03514-3