Abstract

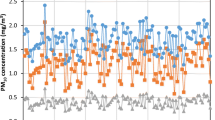

Diesel particulate matter (DPM) is considered carcinogenic to humans by the International Agency for Research on Cancer (IARC), and mine workers have some of the highest exposures to DPM in the USA. Therefore, mines have been developing control strategies for reducing DPM exposures of mine workers. Many of these strategies include engineering and administrative controls. In addition to these types of controls, a respirator program is used at some mines to provide further protection to mine workers where elevated concentrations of DPM exist. However, sometimes mine workers may feel restricted by the use of a half-mask respirator or inconvenienced by the requirement to remove facial hair. Another option which may be more appealing to some mine workers than a half-mask respirator is an airstream helmet, which provides filtered air in the breathing zone of the worker. The airstream helmet does not restrict breathing, provides some cooling, and does not require the worker to be clean shaven to work properly. These helmets are being used to help reduce respirable dust exposures in some coal mines, and this study investigated how effective this helmet may be for reducing DPM exposures. The airstream helmet with a HEPA filter was found to reduce DPM exposures by over 99% in static conditions by both mass and particle counting data. The airstream helmet can be an important part of a mine’s DPM control plan because it can provide clean air into a mine worker’s breathing zone in areas of elevated concentrations.

Similar content being viewed by others

References

Attfield MD, Schleiff PL, Lubin JH, Blair A, Stewart PA, Vermeulen R, Coble JB, Silverman DT (2012) The diesel exhaust in mine workers study: a cohort mortality study with emphasis on lung cancer. J Natl Cancer Inst 104(11):869–883

Silverman DT, Samanic CM, Lubin JH, Blair A, Stewart PA, Vermeulen R, Coble JB, Rothman N, Schleiff PL, Travis WD, Ziegler RG, Wacholder S, Attfield MD (2012) The diesel exhaust in mine workers study: a nested case-control study of lung cancer and diesel exhaust. J Natl Cancer Inst 104(11):855–868

Ping C, Guang X (2017) A review of the health effects and exposure-responsible relationship of diesel particulate matter for underground mines. Int J Min Sci Technol 27(5):831–838

IARC (2012) IARC: diesel engine exhaust carcinogenic. Press release N° 213. International Agency for Research on Cancer World Health Organization June 12

Pronk A, Coble J, Stewart PA (2009) Occupational exposure to diesel engine exhaust: a literature review. J Expo Sci Environ Epidemiol 19(5):443–457

Vermeulen R, Silverman DT, Garshick E et al (2014) Exposure-response estimates for diesel engine exhaust and lung cancer mortality based on data from three occupational cohorts. Environ Health Perspect 2014(122):172–177

MSHA (2001) 30 CFR Part 57, Diesel particulate matter exposure of underground metal and nonmetal mine workers; final rule. Mine Safety and Health Administration, Fed Reg 66(13) 5706

MSHA (2006) 30 CFR Part 57, Diesel particulate matter exposure of underground metal and nonmetal mine workers; final rule. Mine Safety and Health Administration, Fed Reg 71(96), 28924

MSHA (2008) Enforcement of diesel particulate matter final limit at metal and nonmetal underground mines. U.S. Department of Labor, mine safety and health administration, program policy letter no. P08-IV-01 [www.msha.gov/regs/complian/ppls/2008/PPL08-IV-1.pdf]

Bugarski AD, Schnakenberg GH Jr, Hummer JA, Cauda E, Janisko SJ, Patts LD (2009) Effects of diesel exhaust after treatment devices on concentrations and size distribution of aerosols in underground mine air. Env Sci Tech 43:6737–6743

Bugarski A, Janisko S, Cauda E, Noll J, Mischler S, 2012, Controlling exposure to diesel emissions in underground mines. SME. ISBN-13: 9780873353601

Paraszczak J, Svedlund E, Fytas K, Laflamme M (2014) Electrification of loaders and trucks – A step towards more sustainable underground mining, RE&PQJ 1(12)

Treaftis HN, Tomb TF, Carden HF (1981) Laboratory evaluation of the RACAL airstream helmet. U.S. Dept. of labor, mine safety and health administration, IR 1130

Cecala AB, Volkwein JC, Thimons ED, Urban CW (1981) Protection factors of the airstream helmet. Pittsburgh, PA: U.S. Department of the Interior, Bureau of Mines, RI 8591. NTIS No PB 82-135575

Potts JD, Divers EF (1991) Powered dust-filtering helmet reduces exposure to diesel soot. Proceedings of the 3rd symposium on respirable dust in the mine industries, October 17-19, 1990, Pittsburgh, Pennsylvania. Frantz RL, Ramani RV, eds. Littleton, CO: Society for Mining, metallurgy, and exploration, Inc., 1991 Jan:105-107

STP-0012 Determination of Air Flow For Powered Air-Purifying Respirators https://www.cdc.gov/niosh/npptl/stps/pdfs/RCT-APR-0012-508.pdf

Code of Federal Regulations (1995) Approval of respiratory protective devices. U.S. government printing office, Office of the Federal Register, Washington DC, title 42, CFR Part 84

Noll JD, Mischler S, Schnakenberg G, Bugarski A (2006) Measuring diesel particulate matter in underground mines using submicron elemental carbon as a surrogate. In: Mutmansky J, Ramani R (eds) Proceedings for the 11th US north American mine ventilation symposium. State College, Pennsylvania, pp 105–110

Birch ME (2003) West Conshohocken, PA: ASTM international, standard test method for monitoring diesel particulate exhaust in the workplace, published by ASTM as standard test method D6877-03

NIOSH (2016) Monitoring diesel exhaust in the workplace. In: NIOSH manual of analytical methods (NMAM), 5th edition, chapter DL, Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. https://www.cdc.gov/niosh/nmam/pdfs/NMAM_5th Ed, EBook.Pdf

Noll JD, Bugarski A, Vanderslice S, Hummer J (2020) High-sensitivity cassette for reducing limit of detection for diesel particulate matter sampling. Environ Monit Assess 192:333

Noll JD, Timko RJ, McWilliams L, Hall P, Haney R (2005) Sampling results of the improved SKC diesel particulate matter cassette. J Occup Environ Hyg 2:29–37

Noll JD, Janisko S, Mischler S (2013a) Real-time diesel particulate monitor for underground mines. Anal Methods 5(12):2954–2963

Noll JD, Janisko S (2013b) Evaluation of a wearable monitor for measuring real-time diesel particulate matter concentrations in several underground mines. J Occup Environ Hyg 10(12):716–722

Skoog D, West D (1986) Analytical chemistry. Saunders, New York, pp 48–49

Kittelson DB, Watts WF, Johnson JP (2002) Diesel aerosol sampling methodology—CRC E-43 Final Report (181pp.). NTIS Accession no. PB2003–1024181, available from CRC, Alpharetta, GA. Available at http://www.crcao.com/

Khan MY, Shimpi SA, Martin WT (2015) The repeatability and reproducibility of particle number measurements from a heavy duty diesel engine. Emiss Control Sci Technol 1:298–307

Bugarski A, Hummer J (2020) Contribution of various types and categories of diesel-powered vehicles aerosols in underground mine. JOEH 17(4):121–134

Bloomfield J, Greenburg L (1933) Sand and metallic abrasive blasting as an industrial health hazard. J Occup Environ Hyg 15:184–204

Burgess WA, Reist P (1969) Supply rates for powered air-purifying respirators. Am Ind Hyg Assoc J 30(1):1–6

Johnson A, Mackey K, Scott W, Koh F, Chiou Y, Phelps S (2005) Exercise performance while wearing a tight-fitting powered air purifying respirator with limited flow. J Occup Environ Hyg 2(7):368–373

Mackey K, Johnson A, Scott W, Koh F (2005) Over breathing a loose-fitting PAPR, Journal of the International Society for Respiratory Protection, vol 22

Noll J, Cauda E, Vanderslice S, Barone T 2019, Quantification of the effects of carbon on filter media in SKC DPM cassettes on measurements of diesel particulate matter in underground mines, 2019 SME annual meeting, Denver, Colorado, preprint 19–039

Noll JD, Birch ME (2008) Effects of sampling artifacts on occupational samples of diesel particulate matter. Environ Sci Technol 42:5223–5228

Noll J, Gilles S, Wu H, Rubinstein E (2015) The relationship between elemental carbon and diesel particulate matter in underground metal/nonmetal mines in the United States and coal mines in Australia. J Occup Environ Hyg 12:205–211

Golanski L, Guiot A, Tardif F. (2010) Experimental evaluation of individual protection devices against different types of nanoaerosols: graphite, TiO2, and Pt. J Nanopart Res

Held KF, Rundell C, Thibeault R, Ghidoni D, Magoon D, Nguyen T, Fisher A, Parker B, Spenlinhauer T, Gordon J, Nesbitt S (2018) The effectiveness of HEPA filters on DNA. J ABSA Int 23(2):91–95

Morawska L, Ayoko GA, Bae GN, Buonanno G, Chao CYH, Clifford S, Fu SC, Hanninen O, He C, Isaxon C, Mazaheri M, Salthammer T, Waring MS, Wierzbicka A (2017) Airborne particles in indoor environment of homes, schools, offices, and aged care facilities: the main routes of exposure. Environ Int 108:75–83

Parobeck P, Francart W, Ondrey R, Stoltz R, Atchison D, Gerbec E (1989) Application of the RACAL airstream helmet in four underground coal mines. Appl Ind Hyg 4:126–132

Cecala AB, O'Brien AD, Pollock DE, Zimmer JA, Howell JL, McWilliams LJ (2007) Reducing Respirable dust exposure of workers using an improved clothes cleaning process. Int J Miner Res Eng 12(2):73–94

Cecala A, O'Brien AD, Schall J, Colinet J, Franta RJ, Schultz MJ, Haas E, Robinson J, Patts J, Holen BM, Stein R, Weber J, Strebel M, Wilson L, Ellis M (2019) Dust Control Handbook for Industrial Minerals Mining and Processing. Second edition. Pittsburgh, PA: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2019–124 (RI 9701) :1–362

Acknowledgements

We would like to thank Jeremy Brannen and Pat Wiltanger from the National Institute for Occupational Safety and Health (NIOSH) National Personal Protective Technology Laboratory (NPPTL) for performing the airflow tests on the airstream helmet.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Declarations

None to declare.

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Disclaimer

The findings and conclusions in this report are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention. Mention of any company name or product does not constitute endorsement by NIOSH.

Code Availability

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Noll, J., Lee, T., Vanderslice, S. et al. Capability of the Airstream Helmet for Protecting Mine Workers from Diesel Particulate Matter. Mining, Metallurgy & Exploration 38, 635–644 (2021). https://doi.org/10.1007/s42461-020-00352-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00352-0