Abstract

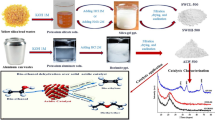

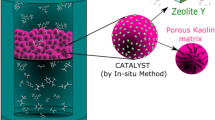

Nickel–alumina cryogel was prepared from aluminium sec-butoxide and nickel acetate by one-pot sol–gel processing and subsequent freeze drying. Catalysis for CO2 reforming of CH4 and carbon formation during the reforming were examined on the cryogel by comparison to those on the corresponding xerogel catalyst prepared by employing normal drying in order to evaluate the utility of the freeze drying. While the catalytic activity was not different significantly between the two sol–gel catalysts, carbon formation was suppressed more markedly on the cryogel than on the xerogel. The surface area and pore volume of the catalyst after the calcination and after the subsequent high-temperature reduction were larger for the cryogel than for the xerogel. XRD, UV-visible, FT-IR, and Raman spectra suggested the principal formation of NiAl2O4 after the calcination for both catalysts, whereas the presence of NiO, leading finally to large nickel particle, was suggested for the xerogel although it may be a small portion. Mean diameter of nickel particles estimated from TEM and XRD showed smaller size for the cryogel than for the xerogel. These results suggested that role of the freeze drying was to improve structural and textual properties of alumina gel as well as to give finer nickel particles throughout the gel.

Highlights

-

Ni/Al2O3 cryogel was synthesized by one-pot sol-gel processing and subsequent freeze drying.

-

Large surface area and pore volume were obtained after calcination and subsequent reduction.

-

Fine nickel particles were formed on alumina after the reduction.

-

Carbon formation during CO2 reforming of CH4 was suppressed.

Similar content being viewed by others

References

Mao XY, Foucher AC, Stach EA, Gorte RJ (2020) J Catal 381:561–569

Huang JJ, Yan Y, Saqline S, Liu W, Liu B (2020) Appl Catal B-Environ 275:119109

Moud PH, Andersson KJ, Lanza R, Engvall K (2016) Appl Catal B-Environ 190:137–146

Fertout RI, Ghelamallah M, Helamallah M, Kacimi, Lopez PN, Corberan VC (2020) Russ J Appl Chem 93:289–298

Rostrup-Nielsen JR, Sehested J, Norskov JK (2002) Adv Catal 47:65

Wang YH, Liu HM, Xu BQ (2009) J Mol Catal A-Chem 299:44–52

Seo JG, Youn MH, Lee HI, Kim JJ, Yang E, Chung JS, Kim P, Song IK (2008) Chem Eng J 141:1–304

Yoo J, Bang Y, Han SJ, Kang TH, Lee J, Song IK (2013) J Mol Catal A-Chem 380:28–33

Seo JG, Youn MH, Bang Y, Song IK(2010) Int J Hydrogen Energy 35:12174–12181

Bang Y, Seo JG, Youn MH, Song IK (2012) Int J Hydrog Energy 37:1436–1443

Gao BY, Wang IW, Ren LL, Haines T, Hu JL (2019) Ind Eng Chem Res 58:798–807

Klvana D, Chaouki J, Repelinlacroix M, Pajonk GM (1989) J Phys 50:C429

Kirchnerova J, Klvana D, Chaouki J (2000) Appl Catal A-Gen 196:191–198

Osaki T (2018) J Porous Mater 25:697–711

Osaki T, Horiuchi T, Sugiyama T, Suzuki K, Mori T (1998) J Non-Cryst Solids 225:111–114

Li J, Zhang QJ, Zhao YH, Qi P, Shao C (2017) React Kinet Mech Catal 122:1193–1202

Dekkar S, Tezkratt S, Sellam D, Ikkour K, Parkhomenko K, Martinez-Martin A, Roger AC (2020) Catal Lett 150:2180–2199

Lee KM, Lee WY (2002) Catal Lett 83:65–70

Kim P, Kim Y, Kim H, Song IK, Yi J (2004) Appl Catal A-Gen 272:157–166

Lopez-Fonseca R, Jimenez-Gonzalez C, de Rivas B, Gutierrez-Ortiz JI (2012) Appl Catal A-Gen 437:53–62

Mizushima Y, HORI M (1994) J Non- Cryst Solids 167:1–8

Tarte P (1967) Spectrochim Acta A23:2127–2143

Busca G, Lorenzelli V, Escribano VS (1992) Chem Matter 4:595–605

Chan SS, Wachs IE (1987) J Catal 103:224–227

Perez-Ramirez J, Mul G, Moulijn JA (2001) Vib Spectrosc 27:75–88

Wang YG, Xiong G, Liu X, Yu XC, Liu LP, Wang JY, Feng ZC, Li C (2008) J Phys Chem C 112:17265–17271

Aminzadeh A, Sarikhani-fard H (1999) Spectrochim Acta A-Mole Biomole Spectrosc 55:1421–1425

Yadav SK, Jeevanandam P (2014). J Alloy Compd 610:567–574

Anderson J. R. (1975) Structure of metallic catalysts. Academic Press, London

The Catalyst Society of Japan (1986) Shokubai Koza, vol. 3. Kodansha, Tokyo

Anjaneyulu C, Kumar V, Vijay B, Suresh K (2013) J Energy Chem 22:853–860

de Sousa HAS, da Silva AN, Castro AJR, Campos A, Filho JM, Oliveira AC (2012) Int J Hydrog Energy 37:12281–12291

Kim JH, Suh DJ, Park TJ, Kim KL (2000) Appl Catal A-Gen 197:191–200

Tang S, Ji L, Lin J, Zeng HC, Tan KL, Li K (2000) J Catal 194:424–430

Bengaard HS, Norskov JK, Sehested J, Clausen BS, Nielsen LP, Molenbroek AM, Rostrup-Nielsen JR (2002) J Catal 209:365–384

Osaki T (2015) Catal Lett 145:1931–1940

Osaki T, Horiuchi T, Sugiyama T, Suzuki K, Mori T (1988) Catal Lett 52:171–180

Osaki T, Mori T (2009) J Non-Cryst Solids 355:31–1596

Acknowledgements

The author thanks Mrs. Kiho Yamada for assistance in the experimental work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Osaki, T. Synthesis of porous and homogeneous Ni/Al2O3 cryogel for CO2 reforming of CH4. J Sol-Gel Sci Technol 97, 291–301 (2021). https://doi.org/10.1007/s10971-020-05441-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05441-6