Abstract

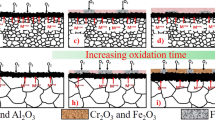

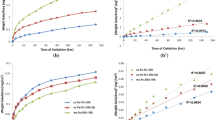

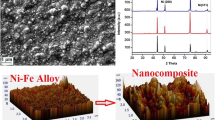

In this paper, microstructure characteristics and phase transitions of Fe-19 wt%Cr-9 wt%Ni nanocrystalline alloy are comprehensively studied during the mechanical alloying and hot pressing sintering processes. Corrosion resistance of the sintered Fe-19 wt%Cr-9 wt%Ni nanocrystalline alloy samples is further analyzed. During the mechanical alloying process, Fe-19 wt%Cr-9 wt%Ni nanocrystalline alloy powders mainly composed of metastable ferrite phase are obtained after mechanical alloying for 8, 16 and 24 h, respectively. In the subsequent hot pressing sintering process, the phase transitions (from ferrite to austenite) occur from 650 to 750 °C for Fe-19 wt%Cr-9 wt%Ni alloy powders milled for 24 h. When the sintering temperature is raised to 1050 °C for 1 h, the ferrite phase has transformed into austenite phase completely, and the obtained grain size of sintered Fe-19 wt%Cr-9 wt%Ni alloy is around 40 nm. Electrochemistry test of the sintered Fe-19 wt%Cr-9 wt%Ni alloy has been operated in 0.5 mol L−1 H2SO4 solution to show the corrosion resistance properties. Results show that the sintered Fe-19 wt%Cr-9 wt%Ni alloy exhibits excellent corrosion resistance, which is proved by higher self-corrosion potential, lower self-corrosion current density and larger capacitive reactance, compared with that of commercial 304 stainless steel.

Similar content being viewed by others

References

T.T. Sasaki, T. Ohkubo, K. Hono, Acta. Mater. 57, 3529 (2009)

Z. Cheng, H. Zhou, Q. Lu, H. Gao, L. Lu, Science 362, 1925 (2018)

Z.X. Hou, X.Y. Li, K. Lu, Science 360, 526 (2018)

W. Len, Y. Wang, Y. Zhou, L. Guo, J.H. Ouyang, Corros. Sci. 53, 1 (2011)

G. Wu, K.C. Chan, L. Zhu, L. Sun, J. Lu, Nature 545, 80 (2017)

Y. Zou, S. Maiti, W. Steurer, R. Spolenak, Acta. Mater. 65, 85 (2014)

D.H. Lee, I.C. Choi, M.Y. Seok, J. He, Z. Lu, J.Y. Suh, M. Kawasaki, M. Kawasaki, J. Jang, J. Mater. Res. 30, 2804 (2015)

R. Lei, S. Xu, M. Wang, H. Wang, Mater. Sci. Eng. A 586, 367 (2013)

C.C. Koch, R.O. Scattergood, K.A. Darling, J.E. Semones, J. Mater. Sci. 43, 7264 (2008)

M. Kapoor, G.B. Thompson, Curr. Opin. Solid State Mater. Sci 19, 138 (2014)

X.H. Shi, Y.Z. Chen, X.Y. Ma, H.T. Wang, F. Liu, Mater. Charact. 103, 58 (2015)

Z.X. Hang, N.Q. Vo, P. Bellon, R.S. Averback, Acta. Mater. 59, 5332 (2011)

W. Liu, C. Zhang, Z. Yang, Z. Xia, Appl. Surf. Sci. 292, 556 (2014)

J.M. Tao, X.K. Zhu, R.O. Scattergood, C.C. Koch, Mater. Des. 50, 22 (2013)

L. Lu, L.B. Wang, B.Z. Ding, K. Lu, Mater. Sci. Eng. A 286, 125 (2000)

M. Azimi, G.H. Akbari, J. Alloys Compd. 555, 112 (2013)

R.S. Lei, M.P. Wang, M.X. Guo, Z. Li, Q.Y. Dong, Trans. Nonferrous Met. Soc. China 19, 272 (2009)

J.M. Dake, C.E.K. Iii, Scr. Mater. 66, 390 (2012)

K.A. Darling, B.K. Vanleeuwen, J.E. Semones, C.C. Koch, R.O. Scattergood, L.J. Kecskes, S.N. Mathaudhu, Mater. Sci. Eng. A 528, 4365 (2011)

X. Li, W. Liu, Y. Xu, C.S. Liu, B.C. Pan, Y.F. Liang, Q.F. Fang, J.L. Chen, G.N. Luo, G.H. Lu, Z.G. Wang, Acta Mater. 109, 115 (2016)

V.S. Saji, R. Cook, Corrosion Protection and Control Using Nanomaterials (Woodhead Publishing, Cambridge, 2012).

M.A. Meyers, A. Mishra, D.J. Benson, Prog. Mater. Sci. 51, 427 (2006)

C. Suryanarayana, Prog. Mater. Sci. 46, 1 (2001)

C. Suryanarayana, E. Ivanov, V. Boldyrev, Mater. Sci. Eng. A 304, 151 (2001)

J.B. Zhou, K.P. Rao, J. Alloys Compd. 384, 125 (2004)

B. Mozafari, M.R. Rahimipour, E. Salahi, S. Farhikhteh, J. Alloys Compd. 481, 616 (2009)

L.H. Tian, M. Fu, W. Xiong, Materials 11, 320 (2018)

M. Krasnowski, S. Gierlotka, S. Ciołek, T. Kulik, Adv. Powder Technol. 30, 1312 (2019)

X. Wen, G. Jin, X.J. Pang, Z.B. Cai, Z.H. Zhang, X.F. Cui, H.D. Wang, B.S. Xu, Mater. Rev. 31, 79 (2017)

C.F. Sun, P.P. Li, S.Q. Xi, Y. Zhou, S.W. Li, X.G. Yang, Mater. Sci. Eng. A 728, 144 (2018)

C. Suryanarayana, M. Norton, X-Ray Diffraction: A Practical Approach (Springer, Berlin, 1998).

C.F. Sun, X.N. Hai, S.Q. Xi, Z. Fan, P.P. Li, W. Wang, J. Alloys Compd. 731, 667 (2018)

M.H. Enayati, E. Dastanpoor, Metall. Mater. Trans. A 44, 3984 (2013)

C. Between, N. As, Modern Developments in Powder Metallurgy (Plenum Press, Berlin, 1973).

C.F. Sun, X.F. Dang, S.W. Li, Rare Met. Mater. Eng. 45, 3115 (2016)

L. Liu, Y. Li, F. Wang, Electrochim. Acta 54, 768 (2008)

Z.J. Zheng, Y. Gao, Y. Gui, M. Zhu, Corros. Sci. 54, 60 (2012)

H. Maleki-Ghaleh, K. Hajizadeh, E. Aghaie, S. Ghobadi Alamdari, M.G. Hosseini, M.H. Fathi, K.O. Zaltin, K.J. Kurzydlowski, Corrosion 71, 367 (2015)

R.K. Gupta, R.K. Singh Raman, C.C. Koch, J. Mater. Sci. 47, 6118 (2012)

R.K. Gupta, R.K. Singh Raman, C.C. Koch, Mater. Sci. Eng. A 494, 253 (2008)

D. Xu, E.H. Han, Y. Xu, Prog. Nat. Sci. 26, 117 (2016)

B.B. He, B. Hu, H.W. Yen, G.J. Cheng, Z.K. Wang, H.W. Luo, M.X. Huang, Science 357, 1029 (2017)

M. Koyama, Z. Zhang, M. Wang, D. Ponge, D. Raabe, K. Tsuzaki, C.C. Tasan, Science 355, 1055 (2017)

G. Günter, Solid State Phase Transformations (Springer, Berlin, 2004).

K. Chvátalová, J. Houserová, M. Šob, J. Vrestal, J. Alloys Compd. 378, 71 (2004)

M.H. Enayati, M.R. Bafandeh, J. Alloys Compd. 454, 1 (2008)

H. Kotan, K.A. Darling, Mater. Charact. 138, 186 (2018)

G.V. Raynor, Trans. Faraday Soc. 45, 698 (1949)

C.F. Sun, S.Q. Xi, Y. Zhang, X.X. Zheng, J.E. Zhou, Acta Metall Sin.-Engl. Lett. 28, 1074 (2015)

S.Q. Xi, K.S. Zuo, X.G. Li, G. Ran, J.E. Zhou, Acta Mater. 56, 6050 (2008)

R.A. Andrievski, J. Mater. Sci. 49, 1449 (2014)

Acknowledgements

The authors would like to acknowledge the financial support of the National Natural Science Foundation of China (Nos. 51271143 and 51705391), the Fundamental Research Funds for the Central Universities, Key and Shaanxi creative talents promotion plan-technological innovation team (No. 2017KCT-05) and the Project of equipment pre-research field fund (No. 6140922010301). We also thank the Instrument Analysis Center of Xi’an Jiaotong University for providing characterization analysis. The authors are grateful to Dr. Panpan Li and Wei Yang for their kindly assistance in polishing our paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Sun, C., Xi, S., Dang, X. et al. Formation of Fe-19 wt%Cr-9 wt%Ni Nanocrystalline Alloy with Excellent Corrosion Resistance: Phase Transition and Microstructure. Acta Metall. Sin. (Engl. Lett.) 34, 825–833 (2021). https://doi.org/10.1007/s40195-020-01178-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01178-x