Abstract

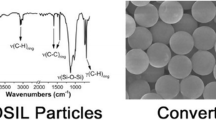

Abundant applications of silica nanoparticles (SiNPs) have motivated many research groups for silica nanoparticles synthesis with tuned properties. Here we show the formation of SiNPs using the top-down method in a wet attrition mill with effective use of surfactants sodium laurylsulfate (SLS) and Tween-80. The attrition milling was facilitated by using zirconium beads as milling media. The effects of surfactant concentration on particle size distribution have been studied with a particle size analyzer using the dynamic light scattering technique (DLS). The optimum conditions for wet milling with surfactant concentration were evaluated experimentally. The field emission scanning electron microscopy (FE-SEM) analysis confirmed particle size and particle shape. The energy-dispersive X-ray spectroscopy (EDX) exhibited the presence of silicon and oxygen as elemental constituents of SiNPs. The FEG - Transmission electron microscope and HR-TEM analysis identified SiNPs of spherical shape in the size range from 21 nm to 46 nm. The X-ray diffraction (XRD) peaks revealed the presence of SiNPs polycrystallite size as 35.54 nm and 40.63 nm for 5 wt % Tween-80 and 5 wt% SLS, respectively. The selected area electron diffraction (SAED) pattern analysis exhibited a polycrystalline structure of SiNPs. Fourier transform infrared spectroscopy (FTIR) peaks confirmed the purity of SiNPs and the presence of Si-O bond. The foam formation and foam stability were analyzed to explore the effects of foam formation on the wet milling process. These experimentations propose the effective use of surfactants in the milling method for the production of SiNPs.

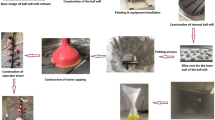

Graphical Abstract

Similar content being viewed by others

Data Availability

The data and material regarding the work presented here can be available on request till 12 months from the first online publication date of this paper.

References

Yokoyama T, CC H (2005) Nanoparticle technology for the production of functional materials. KONA Powder Part J 23:7–17. https://doi.org/10.14356/kona.2005006

Kang Z, Liu Y, Lee S-T (2011) Small-sized silicon nanoparticles: new nanolights and nanocatalysts. Nanoscale 3(3):777–791. https://doi.org/10.1039/C0NR00559B

He Y et al (2009) Ultrastable, highly fluorescent, and water-dispersed silicon-based nanospheres as cellular probes. Angew Chem Int Ed 48(1):128–132. https://doi.org/10.1002/anie.200802230

Clark RJ, Dang MK, Veinot JG (2010) Exploration of organic acid chain length on water-soluble silicon quantum dot surfaces. Langmuir 26(19):15657–15664. https://doi.org/10.1021/la102983c

Kang Z et al (2007) Silicon quantum dots: a general photocatalyst for reduction, decomposition, and selective oxidation reactions. J Am Chem Soc 129(40):12090–12091. https://doi.org/10.1021/ja075184x

Li M et al (2016) Nanomilling of drugs for bioavailability enhancement: a holistic formulation-process perspective. Pharmaceutics 8(2):17. https://doi.org/10.3390/pharmaceutics8020017

Li Z et al (2020) Understanding the mechanisms of silica nanoparticles for nanomedicine. WIREs Nanomed Nanobiotechnol :e1658. https://doi.org/10.1002/wnan.1658

Jeelani PG et al (2019) Multifaceted application of silica nanoparticles. A review. Silicon :1–18. https://doi.org/10.1007/s12633-019-00229-y

Rabinow BE (2004) Nanosuspensions in drug delivery. Nat Rev Drug Discov 3(9):785–796. https://doi.org/10.1038/nrd1494

Ohemeng PO et al (2020) Iron and silver nanostructures: Biosynthesis, characterization and their catalytic properties. Nano-Struct Nano-Objects 22:100453. https://doi.org/10.1016/j.nanoso.2020.100453

Akl M et al (2013) Preparation and characterization of silica nanoparticles by wet mechanical attrition of white and yellow sand. J Nanomed Nanotechnol 4(183):1–14. https://doi.org/10.4172/2157-7439.1000183

Nilssen BE, Kleiv RA (2020) Silicon powder properties produced in a planetary ball mill as a function of grinding time, grinding bead size and rotational speed. Silicon :1–11. https://doi.org/10.1007/s12633-019-00340-0

Matavos-Aramyan S, Jazebizadeh MH, Babaei S (2020) Investigating CO2, O2 and N2 permeation properties of two new types of nanocomposite membranes: Polyurethane/silica and polyesterurethane/silica. Nano-Struct Nano-Objects 21:100414. https://doi.org/10.1016/j.nanoso.2019.100414.

Jung HJ et al (2015) Physicochemical properties of ball milled boron particles: Dry vs. wet ball milling process. Powder Technol 269:548–553. https://doi.org/10.1016/j.powtec.2014.03.058

Patel CM, Chakraborty M, Murthy ZVP (2014) Preparation of fenofibrate nanoparticles by combined stirred media milling and ultrasonication method. Ultrason Sonochem 21(3):1100–1107. https://doi.org/10.1016/j.ultsonch.2013.12.001

Patel CM, Chakraborty M, Murthy ZVP (2016) Fast and scalable preparation of starch nanoparticles by stirred media milling. Adv Powder Technol 27(4):1287–1294. https://doi.org/10.1016/j.apt.2016.04.021

Wagener P et al (2012) Physical fabrication of colloidal ZnO nanoparticles combining wet-grinding and laser fragmentation. Appl Phys A 108(4):793–799. https://doi.org/10.1007/s00339-012-6971-x

Patel CM, Chakraborty M, Murthy ZVP (2015) Influence of pH on the stability of alumina and silica nanosuspension produced by wet grinding. Part Sci Technol 33(3):240–245. https://doi.org/10.1080/02726351.2014.978425

Vital A et al (2008) Ultrafine comminution of dental glass in a stirred media mill. Chem Eng Sci 63(2):484–494. https://doi.org/10.1016/j.ces.2007.09.027

Merisko-Liversidge E, Liversidge GG (2011) Nanosizing for oral and parenteral drug delivery: a perspective on formulating poorly-water soluble compounds using wet media milling technology. Adv Drug Deliv Rev 63(6):427–440. https://doi.org/10.1016/j.addr.2010.12.007.

Patel CM, Murthy Z, Chakraborty M (2012) Effects of operating parameters on the production of barium sulfate nanoparticles in stirred media mill. J Ind Eng Chem 18(4):1450–1457. https://doi.org/10.1016/j.jiec.2012.02.005

Patravale V, Date AA, Kulkarni R (2004) Nanosuspensions: a promising drug delivery strategy. J Pharm Pharmacol 56(7):827–840. https://doi.org/10.1211/0022357023691

Ali ME et al (2013) Surfactant assisted ball milling: a simple top down approach for the synthesis of controlled structure nanoparticle. Advanced materials research 832:356–361. https://doi.org/10.4028/www.scientific.net/AMR.832

Nouri A, Wen C (2014) Surfactants in mechanical alloying/milling: a catch-22 situation. Crit Rev Solid State Mater Sci 39(2):81–108. https://doi.org/10.1080/10408436.2013.808985

Bartos C et al (2016) The effect of an optimized wet milling technology on the crystallinity, morphology and dissolution properties of micro-and nanonized meloxicam. Molecules 21(4):507. https://doi.org/10.3390/molecules21040507

Smith G et al (2015) Quantification of residual crystallinity in ball milled commercially sourced lactose monohydrate by thermo-analytical techniques and terahertz spectroscopy. Eur J Pharm Biopharm 92:180–191. https://doi.org/10.1016/j.ejpb.2015.02.026

Peltonen L, Hirvonen J (2010) Pharmaceutical nanocrystals by nanomilling: critical process parameters, particle fracturing and stabilization methods. J Pharm Pharmacol 62(11):1569–1579. https://doi.org/10.1111/j.2042-7158.2010.01022.x

Ghobrial S et al (2019) Characterization of amorphous Ni-Nb-Y nanoparticles for the hydrogen evolution reaction produced through surfactant-assisted ball milling. Electrocatalysis 10(6):680–689. https://doi.org/10.1007/s12678-019-00556-z

Radhip NR (2015) Synthesis of silica nanoparticles from malpe beach sand using planetary ball mill method. J Pure Appl Ind Phys 5:165–172

Kwade A (1999) Wet comminution in stirred media mills—research and its practical application. Powder Technol 105(1–3):14–20. https://doi.org/10.1016/S0032-5910(99)00113-8

Bilgili E, Hamey R, Scarlett B (2004) Production of pigment nanoparticles using a wet stirred mill with polymeric media. China Particuology 2(3):93–100. https://doi.org/10.1016/S1672-2515(07)60032-3

Krishna S, Patel CM (2019) Preparation of coconut shell nanoparticles by wet-stirred media milling. Mater Lett 257:126738. https://doi.org/10.1016/j.matlet.2019.126738.

Sakthivel S, Krishnan VV, Pitchumani B (2008) Influence of suspension stability on wet grinding for production of mineral nanoparticles. Particuology 6(2):120–124. https://doi.org/10.1016/j.partic.2007.12.001

Brinker CJ, Scherer GW (2013) Sol-gel science: the physics and chemistry of sol-gel processing. Academic, Cambridge. https://doi.org/10.1016/C2009-0-22386-5

Morris MC, McMurdie HF, Evans EH, Paretzkin B, Parker HS, a.N.C.P.U.S (1981) Standard x-ray diffraction powder patterns, sect. 18 data for 58 substances. Department of Commerce/National Bureau of Standards, Gaithersburg

Zhao L et al (2007) Crystallization of amorphous SiO2 microtubes catalyzed by lithium. Adv Func Mater 17(12):1952–1957. https://doi.org/10.1002/adfm.200601104.

Funding

Authors thank the Ministry of Education, Government of India, for the scholarship given to SD. The authors also acknowledge SVNIT-Surat for providing the necessary facility for the research work.

Author information

Authors and Affiliations

Contributions

SD carried out experiments and collected the data. VNL conceived the research, devised the research plan and guided the work thoroughly. SD and VNL designed the experiments, and interpreted the results. SD, CMP and VNL wrote the manuscript. VNL and CMP supervised the work.

Corresponding author

Ethics declarations

No any animal was involved in this study. This work does not involve any animal testing.

Conflict of Interest

The authors declare that they have no conflicts of interest.

Consent for Publication

All the authors give consent for publication of this work, here.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Doke, S.D., Patel, C.M. & Lad, V.N. Improving Performance of the Synthesis of Silica Nanoparticles by Surfactant-incorporated Wet Attrition Milling. Silicon 14, 913–922 (2022). https://doi.org/10.1007/s12633-020-00871-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00871-x