Abstract

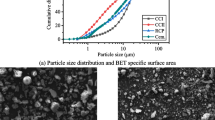

This study investigates the feasibility of using granulated blast furnace slag (GBFS) as fine aggregates for high-performance cement-based (HPCB) materials. The mixture ratio of HPCB materials using GBFS as fine aggregates is calculated based on the dense packing theory of aggregates and the minimum water requirement. A series of cement-based material mixes are prepared with three water binder ratios (0.16, 0.18, and 0.2) and three GBFS replacement ratios (0%, 50%, and 100%). Various properties of the cement-based materials, such as the compressive strength, flexural strength, splitting tensile strength, and elastic modulus, are studied. The research on the selected HPCB material compositions using scanning electronic microscopy (SEM), hardened concrete pore structure determination (HCPD), and mercury intrusion porosimetry (MIP) enables a further understanding of the relationship between the mechanical properties and microstructures. The test results show that it is feasible to produce HPCB materials using GBFS as fine aggregates. Despite its large crushing value index and irregular particle shape, GBFS has hydraulic properties that can make up for these disadvantages. GBFS and mixed fine aggregate cement-based materials with good properties can be prepared with a reasonable mix design. The strength of such cement-based materials is consistent with that of ordinary quartz sand (QS) fine aggregate cement-based materials. The compressive, flexural, and splitting tensile strengths of GBFS and mixed fine aggregate cement-based materials may be higher than those of ordinary QS fine aggregate HPCB materials. The relationship between the compressive strength and porosity is in agreement with the formulas proposed by Powers, Ryshkevitch, Schiller, and Hasselman.

Similar content being viewed by others

Data Availability

All data generated or analysed during this study are included in this published article.

References

Abid M, Hou X, Zheng W, Hussain RR (2017) High temperature and residual properties of reactive powder concrete–a review. Constr Build Mater 147:339–351. https://www.sciencedirect.com/science/article/pii/S0950061817307389?via%3Dihub

Zhao H, Jiang K, Yang R, Tang Y, Liu J (2020) Experimental and theoretical analysis on coupled effect of hydration, temperature and humidity in early-age cement-based materials. Int J Heat Mass Tran 146:118784. https://www.sciencedirect.com/science/article/abs/pii/S0017931019322628

Gholampour A, Ozbakkaloglu T (2017) Performance of sustainable concretes containing very high volume class-F fly ash and ground granulated blast furnace slag. J Clean Prod 162:1407–1417. https://www.sciencedirect.com/science/article/pii/S095965261731257X?via%3Dihub

Zhao S, Sun W (2014) Nano-mechanical behavior of a green ultra-high performance concrete. Constr Build Mater 63:150–160. https://www.sciencedirect.com/science/article/pii/S0950061814003468?via%3Dihub

NewazKhan MN, KumerSaha A (2020) Prabir KumarSarker, reuse of waste glass as a supplementary binder and aggregate for sustainable cement-based construction materials: a review. J Build Eng 28:101052. https://www.sciencedirect.com/science/article/pii/S2352710219309751

Parron-Rubio ME, Perez-García F et al (2018) Concrete properties comparison when substituting a 25% cement with slag from different provenances. Materials 11:1029. http://apps.webofknowledge.com/full_record.do?product=UA&search_mode=GeneralSearch&qid=60&SID=8CjdCINk8BRmhQlmzp2&page=1&doc=1

Fonseca N, De Brito J, Evangelista L (2011) The influence of curing conditions on the mechanical performance of concrete made with recycled concrete waste. J Cem Concr 33:637–643. https://repositorio.ipl.pt/bitstream/10400.21/2254/1/The%20influence%20of%20curing%20conditions%20on%20the%20mechanical%20performance%20of%20concrete%20made%20with%20recycledconcrete%20waste.rep.pdf

DejianShen KL, ChuyuanWen, et al. (2019) Early-age cracking resistance of ground granulated blast furnace slag concrete. Constr Build Mater 222:278–287. https://www.sciencedirect.com/science/article/abs/pii/S0950061819314333#kg005

Ramakrishnan K, Pugazhmani G, Sripragadeesh R, Muthu D, Venkatasubramanian C (2017) Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnaceslag as supplementary cementitious materials. Constr Build Mater 156:739–749. https://www.sciencedirect.com/science/article/pii/S0950061817317440?via%3Dihub

Sadok AH, Courard L (2018) Chloride diffusion and oxygen permeability of mortars with low active blast furnace slag. Constr Build Mater 181:319–324. https://www.sciencedirect.com/science/article/pii/S0950061818314429?via%3Dihub

Karthik A, Sudalaimani K, Vijaya Kumar CT (2017) Investigation on mechanical properties of fly ash-ground granulated blast furnace slag based self curing bio-geopolymer concrete. Constr Build Mater 149:338–349. https://www.sciencedirect.com/science/article/pii/S0950061817310279?via%3Dihub

Sanjuán MÁ, Estévez E, Argiz C, Barrio D d (2018) Effect of curing time on granulated blast-furnace slag cement mortars carbonation. Cement Concrete Comp 90:257–265. https://www.sciencedirect.com/science/article/abs/pii/S0958946517308582

Statistics data China of National Bureau (2018). http://data.stats.gov.cn/easyquery.htm?cn=C01

Angulo-Ramírez DE, de Gutiérrez RM, Medeiros M (2018) Alkali-activated Portland blast furnace slag cement mortars performance to alkali-aggregate reaction. Constr Build Mater 179:49–56. https://www.sciencedirect.com/science/article/pii/S0950061818312674?via%3Dihub

Yoda A, Yokomuro T (1984) Study of mixed sand concrete, Summaries of Technical Papers of Annual Meeting of the Architectural Institute of Japan (Kanto), 9–10

Yuksel I, Ozkan O, Bilir T (2006) Use of granulated blast-furnace slag in concrete as fine aggregate. ACI Mater J 103:203–208. http://connection.ebscohost.com/c/articles/20973923/use-granulated-blast-furnace-slag-concrete-as-fine-aggregate

Ch Srinivasarao S, Reddy VB (2020) Study of standard grade concrete consisting of granulated blast furnace slag as a fine aggregate. 1st International Conference on Advanced Lightweight Materials and Structures (ICALMS), 2020. Mater Today-Proc 27:859–865

Yüksel I, Bilir T (2007) Usage of industrial by-products to produce plain concrete elements. Constr Build Mater 21:686–694. https://www.sciencedirect.com/science/article/abs/pii/S0950061806001826

Topçu IB, Bilir T (2010) Effect of nACI Mater Jon-ground-granulated blast-furnace slag as fine aggregate on shrinkage cracking of mortars 107:545–553

Bilir T (2012) Effects of non-ground slag and bottom ash as fine aggregate on concrete permeability properties. Constr Build Mater 26:730–734. https://www.sciencedirect.com/science/article/abs/pii/S0950061811003503

Bilir T, Gencel O, Topcu IB (2016) Prediction of restrained shrinkage crack widths of slag mortar composites by Takagi and Sugeno ANFIS models. Neural Comput Appl 27:2523–2536. http://www.docin.com/p-1886679423.html

Bilir T, Yüksel I, Topcu IB, Gencel O (2017) Effects of bottom ash and granulated blast furnace slag as fine aggregate on abrasion resistance of concrete. Sci Eng Compos Mater 24:261–269

Patra RK, Mukharjee BB (2018) Influence of granulated blast furnace slag as fine aggregate on properties of cement mortar. Adv Concr Constr 6:611–629

Patra RK, Mukharjee BB (2017) Influence of incorporation of granulated blast furnace slag as replacement of fine aggregate on properties of concrete. J Clean Prod 165:468–476. https://www.sciencedirect.com/science/article/abs/pii/S0959652617315688

Patra RK, Mukharjee BB (2017) Properties of concrete incorporating granulated blast furnace slag as fine aggregate. Adv Concr Constr 5:437–450

Escalante-García JI, Magallanes-Rivera RX, Gorokhovsky A (2009) Waste gypsum-blast furnace slag cement in mortars with granulated slag and silica sand as aggregates. Constr Build Mater 23:2851–2855. https://www.sciencedirect.com/science/article/abs/pii/S0950061809000750

Oren OH, Gholampour A, Gencel O, Ozbakkaloglu T (2020) Physical and mechanical properties of foam concretes containing granulated blast furnace slag as fine aggregate. Constr Build Mater 238:117774. https://www.sciencedirect.com/science/article/abs/pii/S0950061819332271

Fujii T, Sugita A, Ayano T (2017) Improvement of durability of precast concrete member by granulated blast furnace slag sand. J Dis Res 12:456–469

Bagheri A, Nazari A (2014) Compressive strength of high strength class C fly ash-based geopolymers with reactive granulated blast furnace slag aggregates designed by Taguchi method. Mater Design 54:483–490

Dongsheng SHI (2016) Concrete using granulated blast furnace slag as fine aggregate, first ed., Beijing, China

Shi D, Liu Q, Xue X (2018) Study on the durability of concrete using granulated blast furnace slag as fine aggregate. International Symposium on Application of Materials Science and Energy Materials (SAMSE). IOP Conf Series-Mater Sci Eng 322:022025

Architectural Institute of Japan, Recommendation for Practice of Concrete with Blast Furnace Slag Fine Aggregate. Maruzen Publishing Co.,Ltd., Japan, 2013

Bentz DP, Garboczi E (1991) Simulation studies of the effects of mineral admixtures on the cement paste aggregate interfacial zone. ACI Mater J 88:518–529. http://apps.webofknowledge.com/full_record.do?product=UA&search_mode=GeneralSearch&qid=116&SID=8CjdCINk8BRmhQlmzp2&page=1&doc=1

Laskar, MAI, Kumar, R, B.Bhattacharjee (1997) Some aspects of evaluation of concrete through mercury intrusion porosimetry, Cement Concrete Res 27: 93–105. https://www.sciencedirect.com/science/article/pii/S0008884696001925?via%3Dihub

Nedeljkovic’ M, Šavija B, Zuo Y et al (2018) Effect of natural carbonation on the pore structure and elastic modulus of the alkali-activated fly ash and slag pastes. Constr Build Mater 161:687–704. https://www.sciencedirect.com/science/article/pii/S0950061817324005?via%3Dihub

Zhang B, Li S (1995) Determination of the surface fractal dimension for porous media by mercury porosimetry. Ind Eng Chem Res 34:1383–1386. https://doi.org/10.1021/ie00043a044

Ioanna Papayyianni, Maria Stefanidou (2006) Strength-porosity relationships in lime-pozzolan mortars. constr.build.mater. 20:700–705. https://www.sciencedirect.com/science/article/abs/pii/S095006180500111X?np=y

Acknowledgments

The authors are grateful to the financial support by the Science Foundation of the National Science Foundation of China (grant numbers 51868058 and No.51268041), the Science Foundation of Inner Mongolia [grant numbers 2018MS05011] and the Cao Yuan Ying Cai Foundation, Inner Mongolia, China [grant number CYYC5039].

Funding

This work was supported by the National Natural Science Foundation of China [grant numbers 51868058 and 51268041], the Science Foundation of Inner Mongolia [grant numbers 2018MS05011] and the Cao Yuan Ying Cai Foundation, Inner Mongolia, China [grant number CYYC5039].

Author information

Authors and Affiliations

Contributions

Xinxin Xue: Investigation, Data curation, Writing- Original draft preparation.

Dongsheng Shi: Conceptualization, Methodology, Writing- Reviewing and Editing, Funding acquisition.

Ke Li: Formal analysis, Resources, Validation, Supervision.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest pertaining to this work.

Ethical Approval

Not applicable.

Informed Consent

was obtained from all individual participants included in the study.

Declaration of Interests

we declare that we do not have any commercial or associative interests that represent a conflict of interest in connection with the work submitted.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xue, X., Shi, D. & Li, K. Exploration Testing on High-Performance Cement-Based Materials Using Granulated Blast Furnace Slag as Fine Aggregates. Silicon 13, 3537–3554 (2021). https://doi.org/10.1007/s12633-020-00844-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00844-0