Abstract

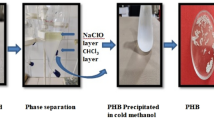

Poly (3-hydroxybutyrate) (PHB) is a good alternative to petroleum-based plastics due to its biodegradable and biocompatible properties. In the present work, Cupriavidus necator ATCC 25207 was used for the first time to produce PHB using fructose, glucose, and acid or enzyme hydrolyzed molasses, a cheap carbon source. The bacterium produced highest PHB with 4.99 g/L, 3.94 g/L, and 15.28 g/L using fructose, glucose, and acid hydrolyzed molasses, respectively. Sulfuric acid and invertase treated molasses yielded 1288% and 529% more PHB than untreated molasses. In addition, acid treated molasses resulted in 151% more PHB but 34.04% less cell growth than enzyme hydrolyzed molasses. This novel finding could have applications in fermentations using molasses in growth or production media. The utilization of glucose by the bacterium was increased by 67.03% through spontaneous mutagenesis. The characterizations of the produced polymers were carried out using FTIR, NMR, XRD, DSC, TGA, and GPC. The molecular weights of PHB samples from acid hydrolyzed molasses and fructose are 3.84 \(\times \) 105 and 1.43 \(\times \) 106 g/mol, respectively. This study shows that C. necator ATCC 25207 has a potential to be used in PHB production using acid hydrolyzed molasses.

Similar content being viewed by others

References

Haider TP, Volker C, Kramm J, Landfester K, Wurm FR (2019) Plastics of the future? the impact of biodegradable polymers on the environment and on society. Angew Chem Int Ed Engl 58:50–62. https://doi.org/10.1002/anie.201805766

Atlas R, Bartha R (1998) Microbial ecology: fundamentals and applications, 4th edn. Benjamin Cummings Publishing Company Inc, Addison Wesley Longman Inc, San Francisco

Anjum A, Zuber M, Zia KM, Noreen A, Anjum MN, Tabasum S (2016) Microbial production of polyhydroxyalkanoates (PHAs) and its copolymers: a review of recent advancements. Int J Biol Macromol 89:161–174. https://doi.org/10.1016/j.ijbiomac.2016.04.069

Alves MI, Macagnan KL, Rodrigues AA, de Assis DA, Torres MM, de Oliveira PD, Furlan L, Vendruscolo CT, Moreira AdS (2017) Poly (3-hydroxybutyrate)-P (3HB): review of production process technology. Ind Biotechnol 13:192–208

Koller M (2018) Chemical and biochemical engineering approaches in manufacturing polyhydroxyalkanoate (PHA) biopolyesters of tailored structure with focus on the diversity of building blocks. Chem Biochem Eng Q 32:413–438

Tan GYA, Chen CL, Li L, Ge L, Wang L, Razaad IMN, Li Y, Zhao L, Mo Y, Wang JY (2014) Start a research on biopolymer polyhydroxyalkanoate (PHA): a review. Polymers 6:706–754. https://doi.org/10.3390/polym6030706

Khanna S, Srivastava AK (2005) Statistical media optimization studies for growth and PHB production by Ralstonia eutropha. Process Biochem 40:2173–2182. https://doi.org/10.1016/j.procbio.2004.08.011

Siracusa V, Rocculi P, Romani S, Dalla Rosa M (2008) Biodegradable polymers for food packaging: a review. Trends Food Sci Technol 19:634–643

Lemoigne M (1926) Produits de deshydration et de Polymerisation de L’acide β= oxybutyrique. Bull Soc Chim Biol 8:770–782

Volodina E, Raberg M, Steinbuchel A (2016) Engineering the heterotrophic carbon sources utilization range of Ralstonia eutropha H16 for applications in biotechnology. Crit Rev Biotechnol 36:978–991. https://doi.org/10.3109/07388551.2015.1079698

Franz A, Rehner R, Kienle A, Grammel H (2012) Rapid selection of glucose-utilizing variants of the polyhydroxyalkanoate producer Ralstonia eutropha H16 by incubation with high substrate levels. Lett Appl Microbiol 54:45–51. https://doi.org/10.1111/j.1472-765X.2011.03171.x

Kersters K (1984) Genus alcaligenes castellani and chalmers 1919. Berg Man Syst Bacteriol 1:361–373

Vega-Castro O, Contreras-Calderon J, León E, Segura A, Arias M, Pérez L, Sobral PJ (2016) Characterization of a polyhydroxyalkanoate obtained from pineapple peel waste using Ralsthonia eutropha. J Biotechnol 231:232–238

Vega-Castro O, León E, Arias M, Cesario MT, Ferreira F, da Fonseca MMR, Segura A, Valencia P, Simpson R, Nuñez H (2020) Characterization and production of a polyhydroxyalkanoate from cassava peel waste: manufacture of biopolymer microfibers by electrospinning. J Polym Environ. https://doi.org/10.1007/s10924-020-01861-1

Raberg M, Peplinski K, Heiss S, Ehrenreich A, Voigt B, Doring C, Bomeke M, Hecker M, Steinbuchel A (2011) Proteomic and transcriptomic elucidation of the mutant Ralstonia eutropha G+1 with regard to glucose utilization. Appl Environ Microbiol 77:2058–2070. https://doi.org/10.1128/AEM.02015-10

Konig C (1969) Constitutive glucose-6-phosphate dehydrogenase in mutants utilizing glucose, which are derived from cryptic wildtype strains. Arch Mikrobiol 67:51–57

Volova T, Kiselev E, Vinogradova O, Nikolaeva E, Chistyakov A, Sukovatiy A, Shishatskaya E (2014) A glucose-utilizing strain, Cupriavidus euthrophus B-10646: growth kinetics, characterization and synthesis of multicomponent PHAs. PLoS ONE 9:e87551. https://doi.org/10.1371/journal.pone.0087551

Poomipuk N, Reungsang A, Plangklang P (2014) Poly-β-hydroxyalkanoates production from cassava starch hydrolysate by Cupriavidus sp. KKU38. Int J Biol Macromol 65:51–64. https://doi.org/10.1016/j.ijbiomac.2014.01.002

Kim BS, Lee SC, Lee SY, Chang HN, Chang YK, Woo SI (1994) Production of poly (3-hydroxybutyric acid) by fed-batch culture of Alcaligenes eutrophus with glucose concentration control. Biotechnol Bioeng 43:892–898

Beaulieu M, Beaulieu Y, Melinard J, Pandian S, Goulet J (1995) Influence of ammonium salts and cane molasses on growth of Alcaligenes eutrophus and production of polyhydroxybutyrate. Appl Environ Microbiol 61:165–169

Song JY, Kim BS (2005) Characteristics of poly (3-hydroxybutyrate-co-4-hydroxybutyrate) production by Ralstonia eutropha NCIMB 11599 and ATCC 17699. Biotechnol Bioprocess Eng 10:603. https://doi.org/10.1007/BF02932302

Baei SM, Najafpour G, Younesi H, Tabandeh F, Issazadeh H, Khodabandeh M (2011) Growth kinetic parameters and biosynthesis of polyhydroxybutyrate in Cupriavidus necator DSMZ 545 on selected substrates. Chem Ind Chem Eng Q/CICEQ 17:1–8

Dalsasso RR, Pavan FA, Bordignon SE, de Aragão GMF, Poletto P (2019) Polyhydroxybutyrate (PHB) production by Cupriavidus necator from sugarcane vinasse and molasses as mixed substrate. Process Biochem 85:12–18

Sharma SK, Mudhoo A (2011) A handbook of applied biopolymer technology: synthesis, degradation and applications. Royal Society of Chemistry, Cambridge

Nonato R, Mantelatto P, Rossell C (2001) Integrated production of biodegradable plastic, sugar and ethanol. Appl Microbiol Biotechnol 57:1–5

Favaro L, Basaglia M, Casella S (2019) Improving polyhydroxyalkanoate production from inexpensive carbon sources by genetic approaches: a review. Biofuels Bioprod Bior 13:208–227. https://doi.org/10.1002/bbb.1944

Chanprateep S (2010) Current trends in biodegradable polyhydroxyalkanoates. J Biosci Bioeng 110:621–632. https://doi.org/10.1016/j.jbiosc.2010.07.014

Koller M, Salerno A, Reiterer A, Malli H, Malli K, Kettl K-H, Narodoslawsky M, Schnitzer H, Chiellini E, Braunegg G (2012) Sugarcane as feedstock for biomediated polymer production. In: Goncalves JF, Correia KD (eds) Sugarcane: production, cultivation and uses. Nova Publishers, New York, pp 105–136

Nielsen SS (2010) Determination of moisture content. Food analysis laboratory manual. Springer, Boston, pp 17–27

Ribeiro PLL, Campos MI, Druzian JI (2017) Novel extracellular polymeric substances produced by Cupriavidus necator IPT 027 grown on glucose and crude glycerol originated from biodiesel. Polym Adv Technol 28:549–556

Chaijamrus S, Udpuay N (2008) Production and characterization of polyhydroxybutyrate from molasses and corn steep liquor produced by Bacillus megaterium ATCC 6748. Agric Eng Int 10:1–12

Kim H-Y, Park J-S, Shin H-D, Lee Y-H (1995) Isolation of glucose utilizing mutant of Alcaligenes eutrophus, its substrate selectivity, and accumulation of poly-β-hydroxybutyrate. J Microbiol 33:51–58

Horwitz W, Chichilo P, Reynolds H (1970) Official methods of analysis of the association of official analytical chemists. Association of Official Analytical Chemists, Washington, DC, USA

Murphy J, Riley JP (1962) A modified single solution method for the determination of phosphate in natural waters. Anal Chim Acta 27:31–36

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Pradhan S, Dikshit PK, Moholkar VS (2018) Production, ultrasonic extraction, and characterization of poly (3-hydroxybutyrate) (PHB) using Bacillus megaterium and Cupriavidus necator. Polym Adv Technol 29:2392–2400

Serafim LS, Lemos PC, Oliveira R, Reis MA (2004) Optimization of polyhydroxybutyrate production by mixed cultures submitted to aerobic dynamic feeding conditions. Biotechnol Bioeng 87:145–160. https://doi.org/10.1002/bit.20085

Gahlawat G, Srivastava AK (2013) Development of a mathematical model for the growth associated Polyhydroxybutyrate fermentation by Azohydromonas australica and its use for the design of fed-batch cultivation strategies. Bioresour Technol 137:98–105. https://doi.org/10.1016/j.biortech.2013.03.023

Dahman Y, Ugwu CU (2014) Production of green biodegradable plastics of poly(3-hydroxybutyrate) from renewable resources of agricultural residues. Bioprocess Biosyst Eng 37:1561–1568. https://doi.org/10.1007/s00449-014-1128-2

Aramvash A, Shahabi ZA, Aghjeh SD, Ghafari M (2015) Statistical physical and nutrient optimization of bioplastic polyhydroxybutyrate production by Cupriavidus necator. Int J Environ Sci Technol 12:2307–2316. https://doi.org/10.1007/s13762-015-0768-3

Sen KY, Hussin MH, Baidurah S (2019) Biosynthesis of poly(3-hydroxybutyrate) (PHB) by Cupriavidus necator from various pretreated molasses as carbon source. Biocatal Agric Biotechnol 17:51–59. https://doi.org/10.1016/j.bcab.2018.11.006

Bozorg A, Vossoughi M, Kazemi A, Alemzadeh I (2015) Optimal medium composition to enhance poly-β-hydroxybutyrate production by Ralstonia eutropha using cane molasses as sole carbon source. Appl Food Biotechnol 2:39–47. https://doi.org/10.22037/afb.v2i3.8883

Stanley A, Kumar HNP, Mutturi S, Vijayendra SVN (2018) Fed-batch strategies for production of PHA using a native isolate of Halomonas venusta KT832796 strain. Appl Biochem Biotechnol 184:935–952. https://doi.org/10.1007/s12010-017-2601-6

Patwardhan PR, Srivastava AK (2004) Model-based fed-batch cultivation of R-eutropha for enhanced biopolymer production. Biochem Eng J 20:21–28. https://doi.org/10.1016/j.bej.2004.04.001

Tripathi AD, Srivastava SK, Singh RP (2013) Statistical optimization of physical process variables for bio-plastic (PHB) production by Alcaligenes sp. Biomass Bioenergy 55:243–250. https://doi.org/10.1016/j.biombioe.2013.02.017

Zafar M, Kumar S, Kumar S, Dhiman AK (2012) Artificial intelligence based modeling and optimization of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) production process by using Azohydromonas lata MTCC 2311 from cane molasses supplemented with volatile fatty acids: a genetic algorithm paradigm. Bioresour Technol 104:631–641. https://doi.org/10.1016/j.biortech.2011.10.024

Wang J, Yu HQ (2007) Biosynthesis of polyhydroxybutyrate (PHB) and extracellular polymeric substances (EPS) by Ralstonia eutropha ATCC 17699 in batch cultures. Appl Microbiol Biotechnol 75:871–878. https://doi.org/10.1007/s00253-007-0870-7

Hablot E, Bordes P, Pollet E, Averous L (2008) Thermal and thermo-mechanical degradation of poly(3-hydroxybutyrate)-based multiphase systems. Polym Degrad Stab 93:413–421. https://doi.org/10.1016/j.polymdegradstab.2007.11.018

Venkateswar Reddy M, Yajima Y, Mawatari Y, Hoshino T, Chang Y-C (2015) Degradation and conversion of toxic compounds into useful bioplastics by Cupriavidus sp. CY-1: relative expression of the PhaC gene under phenol and nitrogen stress. Green Chem 17:4560–4569. https://doi.org/10.1039/c5gc01156f

Kong Y, Hay JN (2002) The measurement of the crystallinity of polymers by DSC. Polymer 43:3873–3878. https://doi.org/10.1016/S0032-3861(02)00235-5

Barham P, Keller A, Otun E, Holmes P (1984) Crystallization and morphology of a bacterial thermoplastic: poly-3-hydroxybutyrate. J Mater Sci 19:2781–2794

Laycock B, Halley P, Pratt S, Werker A, Lant P (2014) The chemomechanical properties of microbial polyhydroxyalkanoates. Prog Polym Sci 39:397–442. https://doi.org/10.1016/j.progpolymsci.2013.06.008

S̆krbić Z, Divjaković V (1996) Temperature influence on changes of parameters of the unit cell of biopolymer PHB. Polymer 37:505–507

Taidi B, Mansfield DA, Anderson AJ (1995) Turnover of Poly(3-hydroxybutyrate) (Phb) and its influence on the molecular-mass of the polymer accumulated by alcaligenes-eutrophus during batch culture. FEMS Microbiol Lett 129:201–205. https://doi.org/10.1111/j.1574-6968.1995.tb07580.x

Sudesh K, Abe H, Doi Y (2000) Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Progress Polym Sci 25:1503–1555. https://doi.org/10.1016/S0079-6700(00)00035-6

Wong PAL, Cheung MK, Lo WH, Chua H, Yu PHF (2004) Investigation of the effects of the types of food waste utilized as carbon source on the molecular weight distributions and thermal properties of polyhydroxybutyrate produced by two strains of microorganisms. E-Polymers. https://doi.org/10.1515/epoly.2004.4.1.324

Mothes G, Schnorpfeil C, Ackermann JU (2007) Production of PHB from crude glycerol. Eng Life Sci 7:475–479. https://doi.org/10.1002/elsc.200620210

Acknowledgements

This project was supported by TUBITAK (The Scientific and Technological Research Council of Turkey; Grant no: 109Y372) and Gebze Technical University (GTU) (Grant No: BAP-2017-A102-18).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ertan, F., Keskinler, B. & Tanriseven, A. Exploration of Cupriavidus necator ATCC 25207 for the Production of Poly(3-hydroxybutyrate) Using Acid Treated Beet Molasses. J Polym Environ 29, 2111–2125 (2021). https://doi.org/10.1007/s10924-020-02020-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-02020-2