Abstract

The paper presents the results of studies of the contact physicochemical interaction of a high-temperature nickel alloy with an investment casting shell material of Al2O3–Al2O3 composition. A comparative assessment of the quality of the surface layer of cast products obtained in conventional ceramic shells of the Al2O3–SiO2 composition has been performed. It is found that, unlike the Al2O3–SiO2 investment casting shell mold, the Al2O3–Al2O3 casting mold interacts with the melt to a much lesser extent. The introduction of non-metallic inclusions occurs to a depth of 10–20 μm (Al2O3–Al2O3 ceramic shell mold), which is noticeably lower than that of cast products obtained in the Al2O3–SiO2 ceramic shell mold (up to 40–70 μm). The roughness value of the casting produced in the Al2O3–Al2O3 ceramic shell mold is 2.5–5.0 μm, and in conventional Al2O3–SiO2 shells this value is 3.5–6.5 μm.

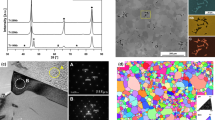

Graphic abstract

The process of interaction of a ceramic shell mold material of the Al2O3–Al2O3 composition with a nickel-based superalloy was investigated.

Similar content being viewed by others

References

N.V. Petrushin, O.G. Ospennikova, I.L. Svetlov, Single-crystal Ni-based superalloys for turbine blades of advanced gas turbine engines. Aviat. mater. technol. 6, 72–103 (2017)

D. Ma, F. Wang, Q. Wu et al., Innovations in casting techniques for single crystal turbine blades of superalloys. Superalloys (2016). https://doi.org/10.1002/9781119075646.ch26

D. Ma, Novel casting processes for single-crystal turbine blades of superalloys. Front. of Mech. Eng. 13(1), 3–16 (2018). https://doi.org/10.1007/s11465-018-0475-0

Yu.A. Bondarenko, Trends in the development of high-temperature metal materials and technologies in the production of modern aircraft gas turbine engines. Aviat. Mater. Technol. 2, 3–11 (2019)

M.F. Moreira, L.B. Fantin, C.R.F. Azevedo, Microstructural characterization of Ni-base superalloy As-cast single crystal (CMSX-4). Inter. Metalcast (2020). https://doi.org/10.1007/s40962-020-00496-1

D. Szeliga, K. Kubiak, G. Jarczyk, The influence of the radiation baffle on predicted temperature gradient in single crystal CMSX-4 castings. Inter. Metalcast. (2013). https://doi.org/10.1007/BF03355555

S.J. Yao, D.Z. Tang, X.G. Liu et al., Interface reaction between DD6 single crystal superalloy and ceramic mold. J. Aeronaut. Mater. (2015). https://doi.org/10.11868/j.issn.1005-5053.2015.6.001

F. Li, H. Ni, L. Yang et al., Investigation of fused alumina based-mold facecoats for dz22b directionally solidified blades. Mater. 12(4), 606 (2019). https://doi.org/10.3390/ma12040606

F. Valenza, M.L. Muolo, A. Passerone, Wetting and interactions of Ni- and Co-based superalloys with different ceramic materials. J. Mater. Sci. 45(8), 2071–2079 (2009). https://doi.org/10.1007/s10853-009-3801-4

J.E. Kanyo, S. Schafföner, R.S. Uwanyuze, K.S. Leary, An overview of ceramic molds for investment casting of nickel superalloys. J. Eur. Ceram. Soc. 40(15), 4955–4973 (2020). https://doi.org/10.1016/j.jeurceramsoc.2020.07.013

Z. Xu, J. Zhong, X. Su et al., Microstructure evolution and mechanical behaviors of alumina-based ceramic shell for directional solidification of turbine blades. J Mater. Res. Tech. 8(1), 876–886 (2018)

D. Szeliga, K. Kubiak, W. Ziaja et al., Investigation of casting–ceramic shell mold interface thermal resistance during solidification process of nickel based superalloy. Exp. Thermal Fluid Sci. 87, 149–160 (2017). https://doi.org/10.1016/j.expthermflusci.2017.04.024

F. Qiu, K. Bu, J. Song et al., Dimensional control of nickel-based single crystal turbine blade investment casting by process control optimization. Inter. Metalcast. (2018). https://doi.org/10.1007/s40962-017-0180-5

M. Xu, S.N. Lekakh, V.L. Richards, Thermal property database for investment casting shells. Inter. Metalcast 10, 329–337 (2016). https://doi.org/10.1007/s40962-016-0052-4

M. Raza, R. Svenningsson, M. Irwin et al., Effects of process related variations on fillablity simulation of thin-walled IN718 structures. Inter. Metalcast. (2018). https://doi.org/10.1007/s40962-017-0189-9

H. Wang, G. Shang, J. Liao et al., Experimental investigations and thermodynamic calculations of the interface reactions between ceramic moulds and Ni-based single-crystal superalloys: role of solubility of Y in the LaAlO3 phase. Ceramics Int. 44(7), 7667–7673 (2018). https://doi.org/10.1016/j.ceramint.2018.01.192

X.Y. Chen, L. Xiao, J.B. Yu et al., Research status of the interface reactions between superalloys and ceramic materials in investment casting. Special Cast. Nonferrous Alloys. 36, 844–848 (2016)

F. Li, X. Chen, Y. Zhao et al., Modification of ceramic shell facecoat for inhibition of sand burning defect on DZ22B directionally solidified blades. Int. J. Adv. Man. Tech. 99(5–8), 1771–1780 (2018)

Y. Venkat, S. Singh, D.K. Das et al., Effect of fine alumina in improving refractoriness of ceramic shell moulds used for aeronautical grade Ni-base superalloy castings. Ceramics Int. 44(11), 12030–12035 (2018). https://doi.org/10.1016/j.ceramint.2018.03.197

L.L. Wang, J.R. Li, D.Z. Tang et al., Interfacial reactions between SiO2–ZrO2 ceramic core and DZ125, DD5, DD6 casting superalloys. J. Mater. Eng. 44, 9–14 (2016)

H. Wang, J. Yang, J. Meng, Y. Yang, Y. Zhou, Wettability and interfacial reactions of a low Hf-containing nickel-based superalloy on Al2O3-based, SiO2-based, ZrSiO4, and CoAl2O4 substrates. Ceram. Int. 46, 22057–22066 (2020). https://doi.org/10.1016/j.ceramint.2020.05.212

W. Everhart, S. Lekakh, V. Richards et al., Corner strength of investment casting shells. Inter. Metalcast. (2013). https://doi.org/10.1007/BF03355541

Z. Li, X. Liu, K. Lv, Study on the strength of short carbon fiber-reinforced silicon sol shells for the investment casting process. Inter. Metalcast. (2019). https://doi.org/10.1007/s40962-019-00362-9

S. Kumar, D.B. Karunakar, Characterization and properties of ceramic shells in investment casting process. Inter. Metalcast. (2020). https://doi.org/10.1007/s40962-020-00421-6

M.S. Varfolomeev, G.I. Shcherbakova, Refractory compositions designed for highly heat-resistant ceramic molds in foundry practice. Refract. Ind. Ceram 59(3), 290–295 (2018). https://doi.org/10.1007/s11148-018-0223-3

Q. Li, J.X. Song, D.G. Wang, Q. Yu, B.C. Xiao, Effect of Cr, Hf and temperature on interface reaction between nickel melt and silicon oxide core. Rare Met. 30, 405–409 (2011). https://doi.org/10.1007/s12598-011-0313-6

L. Zheng, C.B. Xiao, G.Q. Zhang, G.H. Gu, X. Li, X.G. Liu, M. Xue, D.Z. Tang, Investigation of interfacial reaction between high Cr content cast nickel based superalloy K4648 and ceramic cores. J. Aero Mater. 32(3), 10–22 (2012). https://doi.org/10.3969/j.issn.1005-5053.2012.3.003

X.Y. Chen, F. Li, J. Wang, B.D. Sun, Investigations on interface reactions and wettability between melt superalloys and ceramic materials. Key Eng. Mater. 703, 132–137 (2016). https://doi.org/10.4028/www.scientific.net/kem.703.132

J.S. Yao, D.Z. Tang, X.G. Liu et al., Interaction between two Ni-base alloys and ceramic moulds. Mater. Sci. Forum 747–748, 765–771 (2013). https://doi.org/10.4028/www.scientific.net/msf.747-748.765

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Varfolomeev, M.S., Shcherbakova, G.I. Interaction of a Ceramic Casting Mold Material of the Al2O3–Al2O3 Composition with a Nickel-Based Superalloy. Inter Metalcast 15, 1309–1316 (2021). https://doi.org/10.1007/s40962-020-00557-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00557-5