Abstract

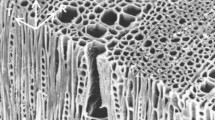

Many new insulation materials are being developed and thermally tested aiming at understanding and improving their insulation characteristics in order to improve the energy performance of new and existing buildings. Bio-sourced materials appear among the new insulation solutions presenting the advantage of being able to save energy on one hand and having a low environmental impact on the other. The wood fiber material is one of the most successful natural insulation materials being recently used in building constructions. It presents many advantages besides its insulation performance; due to its density, it stores moisture thereby improving the indoor air quality; it is also an excellent acoustic insulator because it has a natural tendency to absorb and reduce sounds. In order to evaluate its effectiveness in building applications, this study analyzes the hygrothermal modelling and performance of the wood fiber insulation in building applications by adopting two approaches: A numerical approach using a mathematical model that describes heat and mass transfer within the wood fiber material being considered as porous media. The hygrothermal characteristics of the wood fiber material are first determined experimentally for this purpose, namely the thermal conductivity, the heat capacity, and the isotherms of sorption and desorption. An experimental approach is carried out in controlled and uncontrolled ambiance conditions in order to validate the numerical model. A 50 cm × 50 cm wood fiber sample having an 8 cm thickness is tested for this purpose. A very high accordance is observed between the measured and modelled results for both the temperature and the relative humidity evolutions within the sample at x = 2 cm and x = 4 cm with a mean difference \( \overline{\Delta \mathrm{T}} \) of 0,21 °C at x = 4 cm and 1 °C at x = 2 cm. The maximum recorded differences for the relative humidity are: 5,5% and 4,5% at x = 2 cm and 4 cm respectively. The ability to predict the thermal and the hygric behavior of the wood fiber insulation will thus allow a better understanding of the efficiency of natural insulation materials.

Similar content being viewed by others

Abbreviations

- DT :

-

Mass transport coefficients associated to temperature gradient (m2.s −1.K−1)

- Dθ :

-

Mass transport coefficients associated to moisture gradient (m2.s −1)

- ρ 0 :

-

Solid matrix density (kg/m3)

- L v :

-

Latent vaporization heat (kJ.kg−1)

- ρ l :

-

Water density (kg.m−3)

- Cpm :

-

Average specific heat (J.kg−1.K−1)

- λ*:

-

Equivalent thermal conductivity (W.m−1.K−1)

- T:

-

Temperature (°C)

- RH:

-

Relative humidity (%)

- t:

-

Time (s)

- δ0 :

-

Water vapor permeability (kg.m−1.s−1.Pa−1)

- δa :

-

Air vapor permeability (kg.m−1.s−1.Pa−1)

- ξ:

-

Specific hygric capacity (kg.m−3)

- μ :

-

Water vapor resistance factor (−)

References

Convention-cadre sur les changements climatiques, Conférnce des parties, Paris, 30 novembre - 11 décembre 2015

Agence de la transition écologique ADEME. http://www.ademe.fr

Brook A-M, Price R, Sutherland D, Westerlund N, Andre C (2004) Oil price developments: drivers, economic consequences and policy responses. OECD Economics Working Paper No. 412

Thomsen KE et al (2016) Energy consumption and indoor climate in a residential building before and after comprehensive energy retrofitting. Energy Build 123:8–16

Holopainen R, Tuomaala P, Hernandez P, Häkkinen T, Piira K, Piippo J (2013) Comfort assessment in the context of sustainable buildings: Comparison of simplified and detailed human thermal sensation methods. Build Environ 71:60–70

Biswas K, Shrestha S, Bhandari MS, Desjarlais AO (2016) Insulation materials for commercial buildings in North America: An assessment of lifetime energy and environmental impacts. Energy Build 112:256–269

Khadiran TM, Hussein H, Zainal Z, Rusli R (2015) Advanced energy storage materials for building applications and their thermal performance characterization: A review. Renew Sust Energ Rev 57:916–928

Bories C, Vedrenne E, Paulhe-Masso A, Vilarem G, Sablayrolles C (2016) Development of porous fired clay bricks with bio-based additives: Study of the environmental impacts by Life Cycle Assessment (LCA). Constr Build Mater 125:1142–1151

Bennai F, Issaadi N, Abahri K, Belarbi R, Tahakourt A (2018) Experimental characterization of thermal and hygric properties of hemp concrete with consideration of the material age evolution. Heat Mass Transf 54:1189–1197

Chennouf N, Agoudjil B, Boudenne A, Benzarti K, Bouras F (2018) Hygrothermal characterization of a new bio-based construction material: concrete reinforced with date palm fibers. Constr Build Mater 192:348–356

Kočí V, Jerman M, Pavlík Z, Maděra J, Žák J, Černý R (2020) Interior thermal insulation systems based on wood fiberboards: experimental analysis and computational assessment of hygrothermal and energy performance in the Central European climate. Energy Build 222:110093

Li M, Nicolas V, Khelifa M, El Ganaoui M, Fierro V, Celzard A (2019) Modelling the hygrothermal behaviour of cement-bonded wood composite panels as permanent formwork. Ind Crop Prod 142:111784

Taoukil D, Bouardi A, Sick F, Mimet A, Ezbakhe H, Ajzoul T (2013) Moisture content influence on the thermal conductivity and diffusivity of wood–concrete composite. Constr Build Mater 48:104–115

Rafidiarison H, Rémond R, Mougel E (2015) Dataset for validating 1-D heat and mass transfer models within building walls with hygroscopic materials. Build Environ 89:356–368

Lelievre D, Colinart T, Glouannec P (2014) Hygrothermal behavior of bio-based building materials including hysteresis effects: Experimental and numerical analyses. Energy Build 84:617–627

Rahim M(2015) Analyse et caractérisation du comportement hygrothermique de parois agro-sourcées à l’échelle 1: expérimentation et modélisation, École doctorale Sciences, technologie et santé Amiens

Troppová E, Tippner J, Hrcka R (2017) Thermophysical properties of medium density fiberboards measured by quasi-stationary method: experimental and numerical evaluation. Heat Mass Transf 53:115–125

El-Sawalhi R, Lux J, Salagnac P (2016) Estimation of the thermal conductivity of hemp based insulation material from 3D tomographic images. Heat Mass Transf 52:1559–1569

Mvondo RR, Damfeu JC, Meukam P, Jannot Y (2020) Influence of moisture content on the thermophysical properties of tropical wood species. Heat Mass Transf 56:1365–1378

Latifa E, Lawrence RMH, Shea AD, Walker P (2018) An experimental investigation into the comparative hygrothermal performance of wall panels incorporating wood fibre, mineral wool and hemp-lime. Energy Build 165:76–91

Nguyen DM, Grillet A, Diep TM, Bui Q, Woloszyn M (2020) Characterization of hygrothermal insulating biomaterials modified by inorganic adsorbents. Heat Mass Transf 56:2473–2485

Philip JR, De Vries DA (1957) Moisture movement in porous materials under temperature gradients. Trans Am Geophys Union 38:222–232

Whitaker S (977) Simultaneous heat, mass, and momentum transfer in porous media: a theory of drying. Adv Heat Tran 13(1):119–203

Luikov AV (1957) System of differential equation of heat and mass transfer in capillary porous bodies. Int J Heat Mass Transfer 18(1):1–14

Samson E, Marchand J, Beaudoinc JJ (1999) Describing ion diffusion mechanisms in cement-based materials using the homogenization technique. Cem Concr Res 29:1341–1345

Maghous S, Saad Z, Dormieux L, Canou J (2007) A model for in situ grouting with account for particle filtration. Comput Geotech 34:164–174

Kunzel H (1995) Simultaneous heat and moisture transport in building components: one- and two dimensional calculation using simple parameters. Fraunhofer IRB Verlag, Stuttgart

Fick A (1855) Ûber diffusion. Fick, Annalen der Physik 170(1):59–86. https://doi.org/10.1002/andp.18551700105

Defraeye T, Blocken B, Derome D, Nicolai B (2012) Convective heat and mass transfer modelling at air–porous material interfaces: overview of existing methods and relevance. Chem Eng Sci 74:49–58

Zaknoune A, Glouannec P, Salagnac P (2013) Identification of the liquid and vapour transport parameters of an ecological building material in its early stages. Transp Porous Media 98:589–613

Maalouf C, Le Tran AD, Umurigirwa SB, Lachi M, Douzane O (2014) Study of hygrothermal behaviour of a hemp concrete building envelope under summer conditions in France. Energy Build 77:48–57

Comsol AB (2016) COMSOL multiphysics—Reference manual, version 5.2a. COMSOL AB, Stockholm, Sweden. http://www.comsol.com

Wallace J, Hobbs P. Atmospheric Science, Second Edition: An Introductory Survey (International Geophysics) 2nd Edition

Vololonirina O, Coutand M, Perrin B (2014) Characterization of hygrothermal properties of wood based products - Impact of moisture content and temperature. Constr Build Mater 63:223–233

Limam A, Zerizer AF, Quenard D, Sallee H, Chenak A (2016) Experimental thermal characterization of bio-based materials (Aleppo Pine wood, cork and their composites) for building insulation. Energy Build 116:89–95

Geving S, Lunde E, Holme J (2015) Laboratory investigations of moisture conditions in wood frame walls with wood fiber insulation. Energy Procedia 78:1455–1460

Collet F, Achchaq F, Djellab K, Marmoret L, Beji H (2011) Water vapor properties of two hemp wools manufactured with different treatments. Constr Build Mater 25(2):1079–1085

Sing KSW (1982) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. International Union of Pure and Applied Chemistry :2201–2218

Donohue MD, Aranovich GL (1988) Adsorption hysteresis in porous solids. J Colloid Interface Sci 205:121–130

European Standard NF EN ISO 12571 (2013) Hygrothermal performance of building materials and products- Determination of hygroscopic sorption properties

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and Platinum. J Am Chem Soc 40:1361–1403

Guggenheim E (1966) Application of statistical mechanics. Oxford University Press, Oxford

Anderson R (1946) Modifications of the brunauer, Emmett and Teller equation. J Am Chem Soc 70(5):1727–34

von de Boer HJ (1953) The dynamical character of adsorption. Oxford University Press, Oxford

En-Brunaue S, Emmet P, Teller E (1938) Adsorption of gases in miltimolecular layer. J Am Chem Soc 60(2):309–319

European Standard NF EN ISO 12572 (2001) Hygrothermal performance of building material and products- Determination of water vapour transmission properties

Chamoin J (2014) Optimisation des propriétés (physiques, mécaniques et hydriques) de bétons de chanvre par la maîtrise de la formulation INSA de Rennes

Asan H, Sancaktar Y (1997) Effects of Wall’s thermophysical properties on time lag and decrement factor. Energy Build 28:159–166

Acknowledgments

This work is done as part of the project “Projet citoyen P2AR” financed by the region Nord Pas de Calais, France.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Asli, M., Sassine, E., Brachelet, F. et al. Hygrothermal behavior of wood fiber insulation, numerical and experimental approach. Heat Mass Transfer 57, 1069–1085 (2021). https://doi.org/10.1007/s00231-020-03002-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-03002-9