Abstract

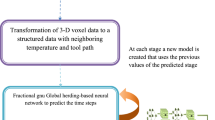

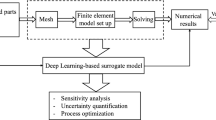

The recent explosion of machine learning (ML) and artificial intelligence (AI) shows great potential in the breakthrough of metal additive manufacturing (AM) process modeling, which is an indispensable step to derive the process-structure-property relationship. However, the success of conventional machine learning tools in data science is primarily attributed to the unprecedented large amount of labeled data-sets (big data), which can be either obtained by experiments or first-principle simulations. Unfortunately, these labeled data-sets are expensive to obtain in AM due to the high expense of the AM experiments and prohibitive computational cost of high-fidelity simulations, hindering the direct applications of big-data based ML tools to metal AM problems. To fully exploit the power of machine learning for metal AM while alleviating the dependence on “big data”, we put forth a physics-informed neural network (PINN) framework that fuses both data and first physical principles, including conservation laws of momentum, mass, and energy, into the neural network to inform the learning processes. To the best knowledge of the authors, this is the first application of physics-informed deep learning to three dimensional AM processes modeling. Besides, we propose a hard-type approach for Dirichlet boundary conditions (BCs) based on a Heaviside function, which can not only exactly enforce the BCs but also accelerate the learning process. The PINN framework is applied to two representative metal manufacturing problems, including the 2018 NIST AM-Benchmark test series. We carefully assess the performance of the PINN model by comparing the predictions with available experimental data and high-fidelity simulation results, using finite element based variational multi-scale formulation method. The investigations show that the PINN, owed to the additional physical knowledge, can accurately predict the temperature and melt pool dynamics during metal AM processes with only a moderate amount of labeled data-sets. The foray of PINN to metal AM shows the great potential of physics-informed deep learning for broader applications to advanced manufacturing. All the data-sets and the PINN code will be made open-sourced in https://yan.cee.illinois.edu/ once the paper is published.

Similar content being viewed by others

References

Zhao C, Fezzaa K, Cunningham R, Wen H, De Carlo F, Chen L, Rollett A, Sun T (2017) Real-time monitoring of laser powder bed fusion process using high-speed x-ray imaging and diffraction. Sci Rep 7(1):1–11

Cunningham R, Zhao C, Parab N, Kantzos C, Pauza J, Fezzaa K, Sun T, Rollett A (2019) Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 363(6429):849–852

Guo Q, Zhao C, Qu M, Xiong L, Hojjatzadeh S, Escano L, Parab N, Fezzaa K, Sun T, Chen L (2020) In-situ full-field mapping of melt flow dynamics in laser metal additive manufacturing. Addit Manuf 31:100939

NIST Additive Manufacturing Benchmark Test Series (AM-BENCH) (2020). https://www.nist.gov/ambench. Accessed 03 Aug 2020

AFRL Additive Manufacturing Modeling Challenge Series (2020). https://www.americamakes.us/america-makes-and-afrl-announce-am-modeling-challenge/. Accessed 07 July 2020

Noble C, Anderson A, Barton N, Bramwell J, Capps A, Chang M, Chou J, Dawson D, Diana E, Dunn T (2017) Ale3d: an arbitrary Lagrangian–Eulerian multi-physics code. Techical report, Lawrence Livermore National Lab.(LLNL), Livermore, CA (United States)

Khairallah S, Anderson A, Rubenchik A, King W (2016) Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45

Roehling TT, Wu SS, Khairallah SA, Roehling JD, Soezeri SS, Crumb MF, Matthews MJ (2017) Modulating laser intensity profile ellipticity for microstructural control during metal additive manufacturing. Acta Mater 128:197–206

Khairallah S, Martin A, Lee J, Guss G, Calta N, Hammons J, Nielsen M, Chaput K, Schwalbach E, Shah M, Chapman G, Willey T, Rubenchik A, Anderson A, Wang Y, Matthews M, King W (2020) Controlling interdependent meso-nanosecond dynamics and defect generation in metal 3d printing. Science 368(6491):660–665

Knapp G, Mukherjee T, Zuback J, Wei H, Palmer T, De A, DebRoy T (2017) Building blocks for a digital twin of additive manufacturing. Acta Mater 135:390–399

Mukherjee T, Wei H, De A, DebRoy T (2018) Heat and fluid flow in additive manufacturing-part i: modeling of powder bed fusion. Comput Mater Sci 150:304–313

Mukherjee T, Wei H, De A, DebRoy T (2018) Heat and fluid flow in additive manufacturing-part ii: Powder bed fusion of stainless steel, and titanium, nickel and aluminum base alloys. Comput Mater Sci 150:369–380

Lin S (2019) Numerical methods and high performance computing for modeling metallic additive manufacturing processes at multiple scales. Ph.D. thesis, Northwestern University

Lin S, Gan Z, Yan J, Wagner G (2020) A conservative level set method on unstructured meshes for modeling multiphase thermo-fluid flow in additive manufacturing processes. Comput Methods Appl Mech Eng 372:113348

Attar E, Körner C (2011) Lattice Boltzmann model for thermal free surface flows with liquid–solid phase transition. Int J Heat Fluid Flow 32(1):156–163

Körner C, Attar E, Heinl P (2011) Mesoscopic simulation of selective beam melting processes. J Mater Process Technol 211(6):978–987

Körner C, Bauereiß A, Attar E (2013) Fundamental consolidation mechanisms during selective beam melting of powders. Model Simul Mater Sci Eng 21(8):085011

Zohdi TI (2014) Additive particle deposition and selective laser processing-a computational manufacturing framework. Comput Mech 54(1):171–191

Zohdi T (2014) A direct particle-based computational framework for electrically enhanced thermo-mechanical sintering of powdered materials. Math Mech Solids 19(1):93–113

Ganeriwala R, Zohdi TI (2014) Multiphysics modeling and simulation of selective laser sintering manufacturing processes. Procedia Cirp 14:299–304

Yan W, Ge W, Qian Y, Lin S, Zhou B, Liu WK, Lin F, Wagner GJ (2017) Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting. Acta Mater 134:324–333

Yan W, Qian Y, Ge W, Lin S, Liu WK, Lin F, Wagner GJ (2018) Meso-scale modeling of multiple-layer fabrication process in selective electron beam melting: inter-layer/track voids formation. Mater Des 141:210–219

Yan W, Lin S, Kafka O, Lian Y, Yu C, Liu Z, Yan J, Wolff S, Wu H, Ndip-Agbor E, Mozaffar M, Ehmann K, Cao J, Wagner G, Liu W (2018) Data-driven multi-scale multi-physics models to derive process-structure-property relationships for additive manufacturing. Comput Mech 61(5):521–541

Yan W, Ge W, Smith J, Lin S, Kafka O, Lin F, Liu W (2016) Multi-scale modeling of electron beam melting of functionally graded materials. Acta Mater 115:403–412

Chen H, Yan W (2020) Spattering and denudation in laser powder bed fusion process: multiphase flow modelling. Acta Mater 196:154–167

Panwisawas C, Qiu C, Anderson MJ, Sovani Y, Turner RP, Attallah MM, Brooks JW, Basoalto HC (2017) Mesoscale modelling of selective laser melting: thermal fluid dynamics and microstructural evolution. Comput Mater Sci 126:479–490

Li X, Zhao C, Sun T, Tan W (2020) Revealing transient powder-gas interaction in laser powder bed fusion process through multi-physics modeling and high-speed synchrotron x-ray imaging. Addit Manuf 35:101362

Megahed M, Mindt H-W, Shula B, Peralta A, Neumann J (2016) Powder bed models-numerical assessment of as-built quality. In: 57th AIAA/ASCE/AHS/ASC structures, structural dynamics, and materials conference, p 1657

Mindt H-W, Desmaison O, Megahed M, Peralta A, Neumann J (2018) Modeling of powder bed manufacturing defects. J Mater Eng Perform 27(1):32–43

Yan J, Yan W, Lin S, Wagner G (2018) A fully coupled finite element formulation for liquid–solid–gas thermo-fluid flow with melting and solidification. Comput Methods Appl Mech Eng 336:444–470

Fan Z, Li B (2019) Meshfree simulations for additive manufacturing process of metals. Integrat Mater Manuf Innov 8(2):144–153

Gan Z, Lian Y, Lin SE, Jones KK, Liu WK, Wagner GJ (2019) Benchmark study of thermal behavior, surface topography, and dendritic microstructure in selective laser melting of inconel 625. Integrat Mater Manuf Innov 8(2):178–193

Liu Z, Wu C, Koishi M (2019) Transfer learning of deep material network for seamless structure-property predictions. Comput Mech 64(2):451–465

Liu Z, Wu C, Koishi M (2019) A deep material network for multiscale topology learning and accelerated nonlinear modeling of heterogeneous materials. Comput Methods Appl Mech Eng 345:1138–1168

Liu Z, Wu C (2019) Exploring the 3d architectures of deep material network in data-driven multiscale mechanics. J Mech Phys Solids 127:20–46

Liu Z, Kafka O, Yu C, Liu W (2018) Data-driven self-consistent clustering analysis of heterogeneous materials with crystal plasticity. In: Oñate E, Peric D, de Souza Neto E, Chiumenti M (eds) Advances in computational plasticity. Springer, pp 221–242

Liu Z, Fleming M, Liu W (2018) Microstructural material database for self-consistent clustering analysis of elastoplastic strain softening materials. Comput Methods Appl Mech Eng 330:547–577

Liu Z, Bessa M, Liu W (2016) Self-consistent clustering analysis: an efficient multi-scale scheme for inelastic heterogeneous materials. Comput Methods Appl Mech Eng 306:319–341

Abadi M, Barham P, Chen J., Chen Z, Davis A, Dean J, Devin M, Ghemawat S, Irving G, Isard M, et al (2016) Tensorflow: a system for large-scale machine learning. In: 12th \(\{\)USENIX\(\}\) symposium on operating systems design and implementation (\(\{\)OSDI\(\}\) 16), pp 265–283

Paszke A, Gross S, Massa F, Lerer A, Bradbury J, Chanan G, Killeen T, Lin Z, Gimelshein N, Antiga L, et al (2019) Pytorch: an imperative style, high-performance deep learning library. In: Wallach H, Larochelle H, Beygelzimer A, d’Alché-Buc F, Fox E, Garnett R (eds) Advances in neural information processing systems, pp 8024–8035

Bastien F, Lamblin P, Pascanu R, Bergstra J, Goodfellow I, Bergeron A, Bouchard N, Warde-Farley D, Bengio Y Theano: new features and speed improvements. arXiv:1211.5590

Jia Y, Shelhamer E, Donahue J, Karayev S, Long J, Girshick R, Guadarrama S, Darrell T (2014)Caffe: convolutional architecture for fast feature embedding. In: Proceedings of the 22nd ACM international conference on multimedia, pp 675–678

Yang X, Barajas-Solano D, Tartakovsky G, Tartakovsky A (2019) Physics-informed Cokriging: a Gaussian-process-regression-based multifidelity method for data-model convergence. J Comput Phys 395:410–431

Raissi M, Perdikaris P, Karniadakis GE (2017) Machine learning of linear differential equations using Gaussian processes. J Comput Phys 348:683–693

Lagaris I, Likas A, Fotiadis D (1998) Artificial neural networks for solving ordinary and partial differential equations. IEEE Trans Neural Netw 9(5):987–1000

Raissi M, Yazdani A, Karniadakis G (2020) Hidden fluid mechanics: learning velocity and pressure fields from flow visualizations. Science 367(6481):1026–1030

Sun L, Gao H, Pan S, Wang J-X (2020) Surrogate modeling for fluid flows based on physics-constrained deep learning without simulation data. Comput Methods Appl Mech Eng 361:112732

Zissis D, Xidias EK, Lekkas D (2015) A cloud based architecture capable of perceiving and predicting multiple vessel behaviour. Appl Soft Comput 35:652–661

Raissi M, Perdikaris P, Karniadakis GE Physics informed deep learning (part i): data-driven solutions of nonlinear partial differential equations. arXiv:1711.10561

He Q, Tartakovsky G, Barajas-Solano D, Tartakovsky A (2019) Physics-informed deep neural networks for multiphysics data assimilation in subsurface transport problems. AGUFM 2019:H34B–02

Tartakovsky A, Marrero C, Perdikaris P, Tartakovsky G, Barajas-Solano D (2020) Physics-informed deep neural networks for learning parameters and constitutive relationships in subsurface flow problems. Water Resour Res 56(5):e2019WR026731

Lu L, Dao M, Kumar P, Ramamurty U, Karniadakis GE, Suresh S (2020) Extraction of mechanical properties of materials through deep learning from instrumented indentation. Proc Nat Acad Sci 117(13):7052–7062

He Q, Chen J (2020) A physics-constrained data-driven approach based on locally convex reconstruction for noisy database. Comput Methods Appl Mech Eng 363:112791

Raissi M, Perdikaris P, Karniadakis G (2019) Physics-informed neural networks: a deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J Comput Phys 378:686–707

Kissas G, Yang Y, Hwuang E, Witschey W, Detre J, Perdikaris P (2020) Machine learning in cardiovascular flows modeling: predicting arterial blood pressure from non-invasive 4d flow mri data using physics-informed neural networks. Comput Methods Appl Mech Eng 358:112623

Dantzig JA, Rappaz M (2016) Solidification: revised & expanded. EPFL Press, Lausanne

Khan P, Debroy T (1984) Alloying element vaporization and weld pool temperature during laser welding of alsl 202 stainless steel. Metall Trans B 15(4):641–644

Collur M, Paul A, Debroy T (1987) Mechanism of alloying element vaporization during laser welding. Metall Trans B 18(4):733–740

Voller V, Swaminathan C (1991) Eral source-based method for solidification phase change. Numer Heat Transf Part B Fundam 19(2):175–189

Liu W, Wang Z, Liu X, Zeng N, Liu Y, Alsaadi F (2017) A survey of deep neural network architectures and their applications. Neurocomputing 234:11–26

Schwing AG, Urtasun R Fully connected deep structured networks. arXiv:1503.02351

Lawrence S, Giles CL, Tsoi AC, Back AD (1997) Face recognition: a convolutional neural-network approach. IEEE Trans Neural Netw 8(1):98–113

Mikolov T, Karafiát M, Burget L, Černockỳ J, Khudanpur S (2010)Recurrent neural network based language model. In: Eleventh annual conference of the international speech communication association

Sengupta N, Sahidullah M, Saha G (2016) Lung sound classification using cepstral-based statistical features. Comput Biol Med 75:118–129

Bishop CM (2006) Pattern recognition and machine learning. Springer, Berlin

Choy CB, Xu D, Gwak J, Chen K, Savarese S (2016) 3d-r2n2: a unified approach for single and multi-view 3d object reconstruction. In: European conference on computer vision. Springer, pp 628–644

Han J, Pei J, Kamber M (2011) Data mining: concepts and techniques. Elsevier, Amsterdam

Liang S, Srikant R Why deep neural networks for function approximation? arXiv:1610.04161

Sibi P, Jones SA, Siddarth P (2013) Analysis of different activation functions using back propagation neural networks. J Theor Appl Inf Technol 47(3):1264–1268

Maas A, Hannun A, Ng A (2013) Rectifier nonlinearities improve neural network acoustic models. In: Proceedings ICML, vol 30, p 3

Eger S, Youssef P, Gurevych I Is it time to swish? comparing deep learning activation functions across nlp tasks. arXiv:1901.02671

Ruder S An overview of gradient descent optimization algorithms. arXiv:1609.04747

Kingma DP, Ba J Adam: a method for stochastic optimization. arXiv:1412.6980

Baydin A, Pearlmutter B, Radul A, Siskind J (2017) Automatic differentiation in machine learning: a survey. J Mach Learn Res 18(1):5595–5637

Tezduyar TE (1992) Stabilized finite element formulations for incompressible flow computations. Adv Appl Mech 28:1–44. https://doi.org/10.1016/S0065-2156(08)70153-4

Takizawa K, Tezduyar TE (2011) Multiscale space-time fluid-structure interaction techniques. Comput Mech 48:247–267. https://doi.org/10.1007/s00466-011-0571-z

Takizawa K, Tezduyar TE (2012) Space-time fluid-structure interaction methods. Math Models Methods Appl Sci 22(supp02):1230001. https://doi.org/10.1142/S0218202512300013

Takizawa K, Tezduyar TE, Kuraishi T (2015) Multiscale ST methods for thermo-fluid analysis of a ground vehicle and its tires. Math Models Methods Appl Sci 25:2227–2255. https://doi.org/10.1142/S0218202515400072

Saad Y, Schultz MH (1986) Gmres: a generalized minimal residual algorithm for solving nonsymmetric linear systems. SIAM J Sci Stat Comput 7(3):856–869

Bazilevs Y, Calo VM, Hughes TJR, Zhang Y (2008) Isogeometric fluid-structure interaction: theory, algorithms, and computations. Comput Mech 43:3–37

Takizawa K, Bazilevs Y, Tezduyar TE (2012) Space-time and ALE-VMS techniques for patient-specific cardiovascular fluid-structure interaction modeling. Arch Comput Methods Eng 19:171–225. https://doi.org/10.1007/s11831-012-9071-3

Masud A, Calderer R (2009) A variational multiscale stabilized formulation for the incompressible Navier–Stokes equations. Comput Mech 44(2):145–160

Zhu L, Goraya S, Masud A (2019) Interface-capturing method for free-surface plunging and breaking waves. J Eng Mech 145(11):04019088

Calderer R, Zhu L, Gibson R, Masud A (2015) Residual-based turbulence models and arbitrary Lagrangian–Eulerian framework for free surface flows. Math Models Methods Appl Sci 25(12):2287–2317

Masud A, Calderer R (2013) Residual-based turbulence models for moving boundary flows: hierarchical application of variational multiscale method and three-level scale separation. Int J Numer Meth Fluids 73(3):284–305

Takizawa K, Tezduyar TE (2012) Computational methods for parachute fluid-structure interactions. Arch Comput Methods Eng 19:125–169. https://doi.org/10.1007/s11831-012-9070-4

Bazilevs Y, Takizawa K, Tezduyar TE (2013) Computational fluid–structure interaction: methods and applications. Wiley, London. https://doi.org/10.1002/9781118483565

Takizawa K, Fritze M, Montes D, Spielman T, Tezduyar TE (2012) Fluid-structure interaction modeling of ringsail parachutes with disreefing and modified geometric porosity. Comput Mech 50:835–854. https://doi.org/10.1007/s00466-012-0761-3

Takizawa K, Tezduyar TE, Boben J, Kostov N, Boswell C, Buscher A (2013) Fluid–structure interaction modeling of clusters of spacecraft parachutes with modified geometric porosity. Comput Mech 52:1351–1364. https://doi.org/10.1007/s00466-013-0880-5

Takizawa K, Tezduyar TE, Boswell C, Tsutsui Y, Montel K (2015) Special methods for aerodynamic-moment calculations from parachute FSI modeling. Comput Mech 55:1059–1069. https://doi.org/10.1007/s00466-014-1074-5

Takizawa K, Bazilevs Y, Tezduyar TE, Korobenko A (2020) Computational flow analysis in aerospace, energy and transportation technologies with the variational multiscale methods. J Adv Eng Comput 4(2):83–117

Ravensbergen M, Helgedagsrud T, Bazilevs YY, Korobenko A (2020) A variational multiscale framework for atmospheric turbulent flows over complex environmental terrains. Comput Methods Appl Mech Eng 368:113182

Bazilevs Y, Hsu M-C, Akkerman I, Wright S, Takizawa K, Henicke B, Spielman T, Tezduyar TE (2011) 3D simulation of wind turbine rotors at full scale. Part I: geometry modeling and aerodynamics. Int J Numer Methods Fluids 65:207–235. https://doi.org/10.1002/fld.2400

Takizawa K, Henicke B, Tezduyar TE, Hsu M-C, Bazilevs Y (2011) Stabilized space-time computation of wind-turbine rotor aerodynamics. Comput Mech 48:333–344. https://doi.org/10.1007/s00466-011-0589-2

Takizawa K, Henicke B, Montes D, Tezduyar TE, Hsu M-C, Bazilevs Y (2011) Numerical-performance studies for the stabilized space-time computation of wind-turbine rotor aerodynamics. Comput Mech 48:647–657. https://doi.org/10.1007/s00466-011-0614-5

Takizawa K, Tezduyar TE, McIntyre S, Kostov N, Kolesar R, Habluetzel C (2014) Space-time VMS computation of wind-turbine rotor and tower aerodynamics. Comput Mech 53:1–15. https://doi.org/10.1007/s00466-013-0888-x

Takizawa K, Bazilevs Y, Tezduyar TE, Hsu M-C, Øiseth O, Mathisen KM, Kostov N, McIntyre S (2014) Engineering analysis and design with ALE-VMS and space-time methods. Arch Comput Methods Eng 21:481–508. https://doi.org/10.1007/s11831-014-9113-0

Takizawa K (2014) Computational engineering analysis with the new-generation space-time methods. Comput Mech 54:193–211. https://doi.org/10.1007/s00466-014-0999-z

Bazilevs Y, Takizawa K, Tezduyar TE, Hsu M-C, Kostov N, McIntyre S (2014) Aerodynamic and FSI analysis of wind turbines with the ALE-VMS and ST-VMS methods. Arch Comput Methods Eng 21:359–398. https://doi.org/10.1007/s11831-014-9119-7

Takizawa K, Tezduyar TE, Mochizuki H, Hattori H, Mei S, Pan L, Montel K (2015) Space-time VMS method for flow computations with slip interfaces (ST-SI). Math Models Methods Appl Sci 25:2377–2406. https://doi.org/10.1142/S0218202515400126

Korobenko A, Bazilevs Y, Takizawa K, Tezduyar TE (2018) Recent advances in ALE-VMS and ST-VMS computational aerodynamic and FSI analysis of wind turbines. In: Tezduyar TE (ed) Frontiers in computational fluid-structure interaction and flow simulation: research from lead investigators under forty–2018, modeling and simulation in science, engineering and technology. Springer, Berlin, pp 253–336. https://doi.org/10.1007/978-3-319-96469-0_7

Otoguro Y, Mochizuki H, Takizawa K, Tezduyar T (2020) Space-time variational multiscale isogeometric analysis of a tsunami-shelter vertical-axis wind turbine. Comput Mech 66(6):1443–1460

Ravensbergen M, Mohamed A, Korobenko A (2020) The actuator line method for wind turbine modelling applied in a variational multiscale framework. Comput Fluids 201:104465

Mohamed A, Bear C, Bear M, Korobenko A (2020) Performance analysis of two vertical-axis hydrokinetic turbines using variational multiscale method. Comput Fluids 200:104432

Bayram A, Korobenko A (2020) Variational multiscale framework for cavitating flows. Comput Mech 66:49–67

Takizawa K, Tezduyar TE, Buscher A, Asada S (2014) Space-time fluid mechanics computation of heart valve models. Comput Mech 54(4):973–986

Terahara T, Takizawa K, Tezduyar T, Bazilevs Y, Hsu M (2020) Heart valve isogeometric sequentially-coupled fsi analysis with the space-time topology change method. Comput Mech 65:1167–1187

Terahara T, Takizawa K, Tezduyar T, Tsushima A, Shiozaki K (2020) Ventricle-valve-aorta flow analysis with the space-time isogeometric discretization and topology change. Comput Mech 65:1343–1363

Bazilevs Y, Takizawa K, Wu M, Kuraishi T, Avsar R, Xu Z, Tezduyar T (2020) Gas turbine computational flow and structure analysis with isogeometric discretization and a complex-geometry mesh generation method. Comput Mech. https://doi.org/10.1007/s00466-020-01919-w

Bazilevs Y, Takizawa K, Tezduyar T, Hsu M, Otoguro Y, Mochizuki H, Wu M (2020) Wind turbine and turbomachinery computational analysis with the ale and space-time variational multiscale methods and isogeometric discretization. J Adv Eng Comput 4(1):1–32

Kozak N, Rajanna M, Wu M, Murugan M, Bravo L, Ghoshal A, Hsu M, Bazilevs Y (2020) Optimizing gas turbine performance using the surrogate management framework and high-fidelity flow modeling. Energies 13(17):4283

Otoguro Y, Takizawa K, Tezduyar TE, Nagaoka K, Avsar R, Zhang Y (2019) Space-time vms flow analysis of a turbocharger turbine with isogeometric discretization: computations with time-dependent and steady-inflow representations of the intake/exhaust cycle. Comput Mech 64(5):1403–1419

Otoguro Y, Takizawa K, Tezduyar TE, Nagaoka K, Mei S (2019) Turbocharger turbine and exhaust manifold flow computation with the space-time variational multiscale method and isogeometric analysis. Comput Fluids 179:764–776. https://doi.org/10.1016/j.compfluid.2018.05.019

Kuraishi T, Takizawa K, Tezduyar T (2019) Space-time computational analysis of tire aerodynamics with actual geometry, road contact, tire deformation, road roughness and fluid film. Comput Mech 64(6):1699–1718

Kuraishi T, Takizawa K, Tezduyar TE (2019) Tire aerodynamics with actual tire geometry, road contact and tire deformation. Comput Mech 63:1165–1185. https://doi.org/10.1007/s00466-018-1642-1

Levine L, Lane B, Heigel J, Migler K, Stoudt M, Phan T, Ricker R, Strantza M, Hill M, Zhang F, Seppala J, Garboczi E, Bain E, Cole D, Allen A, Fox J, Campbell C (2020) Outcomes and conclusions from the 2018 am-bench measurements, challenge problems, modeling submissions, and conference. Integr Mater Manuf Innov 9(1):1–15

Heigel J, Lane B, Levine L (2020) In situ measurements of melt-pool length and cooling rate during 3d builds of the metal am-bench artifacts. Integr Mater Manuf Innov 9(1):31–53

Brandon L, Jarred H, Richard R, Ivan Z, Vladimir K, Jordan W, Thien P, Mark S, Sergey M, Lyle L (2020) Measurements of melt pool geometry and cooling rates of individual laser traces on in625 bare plates. Integr Mater Manuf Innov 9:16–30

Heigel J, Lane B (2018) Measurement of the melt pool length during single scan tracks in a commercial laser powder bed fusion process. J Manuf Sci Eng 140(5):5–12

Acknowledgements

J. Yan is partially supported by ASME Robert M. and Mary Haythornthwaite Research Initiation Award and Singapore National Research Foundation (NRF2018-ITS004-0011). The PINN models were trained at the Texas Advanced Computing Center (Tacc) through a startup allocation on Frontera (CTS20014). These supports are greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, Q., Liu, Z. & Yan, J. Machine learning for metal additive manufacturing: predicting temperature and melt pool fluid dynamics using physics-informed neural networks. Comput Mech 67, 619–635 (2021). https://doi.org/10.1007/s00466-020-01952-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-020-01952-9