Abstract

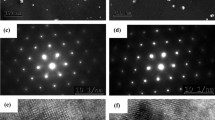

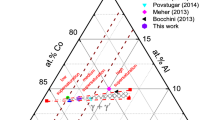

Precipitation behavior of Al3(Sc,Zr) particles in a new high-alloyed Al–Zn–Mg–Cu–Zr–Sc aluminum alloy during homogenization was investigated by use of three-dimensional atom probe, transition electron microscope and high-resolution transition electron microscope. The results indicate that Al3Sc was the precursor of Al3(Sc,Zr) precipitate. The supersaturated solid solution containing Sc decomposed at 250 °C, forming Sc-rich clusters and gradually developing into Al3Sc nuclei. In multicomponent system containing Zr and Sc, the process of Al3Sc nucleus transforming to mature Al3(Sc,Zr) particle was controlled by diffusion. In the early stage of nuclei growth, Zr atoms did not have long-range diffusion capacity, but only Sc atoms diffused freely. With the increase in temperature, Zr atoms began to diffuse over long distance and approach to Al3Sc nuclei driven by chemical potential gradient, and then enrich around them to form Zr-rich thin layer, thus forming Al3(Sc,Zr) structure of Al3Sc core + Zr-rich shell. During isothermal annealing at 440 °C for different holding hours, the mean diameters of the Sc-containing particles after 1 h, 10 h, 36 h and 100 h were 10.9 nm, 15.5 nm, 14.3 nm and 16.7 nm, respectively. The coarsening coefficient for Al3(Sc,Zr) precipitates is about three orders of magnitude smaller than that of Al3Sc particles, showing much better thermal stability.

Similar content being viewed by others

References

Dursun, T.; Soutis, C.: Recent developments in advanced aircraft aluminium alloys. Mater. Des. 56, 862–871 (2014)

Fridlyander, I.N.: Russian aluminum alloys for aerospace and transport applications. Mater. Sci. Forum 331–337, 921–926 (2000)

Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W.S.: Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 280, 102–107 (2000)

Warner, T.: Recently-developed aluminium solutions for aerospace applications. Mater. Sci. Forum 519–521, 1271–1278 (2006)

Dumont, M.; Steuwer, A.; Deschamps, A.; Peel, M.; Withers, P.: Microstructure mapping in friction stir welds of 7449 aluminium alloy using SAXS. Acta Mater. 54, 4793–4801 (2006)

Malarvizhi, S.; Balasubramanian, V.: Fatigue crack growth resistance of gas tungsten arc, electron beam and friction stir welded joints of AA2219 aluminium alloy. Mater. Des. 32, 1205–1214 (2011)

Su, J.Q.; Nelson, T.W.; Mishra, R.; Mahoney, M.: Microstructural investigation of friction stir welded 7050–T651 aluminium. Acta Mater. 51, 713–729 (2003)

Zhao, Y.; Lu, Z.; Yan, K.; Huang, L.: Microstructural characterizations and mechanical properties in underwater friction stir welding of aluminum and magnesium dissimilar alloys. Mater. Des. 65, 675–681 (2015)

Norman, A.F.; Hyde, K.; Costello, F.; Thompson, S.; Birley, S.; Prangnell, P.B.: Examination of the effect of Sc on 2000 and 7000 series aluminium alloy castings: for improvements in fusion welding. Mater. Sci. Eng. A 354, 188–198 (2003)

He, Y.D.; Zhang, X.M.; You, J.H.: Effect of minor Sc and Zr on microstructure and mechanical properties of Al–Zn–Mg–Cu alloy. Trans. Nonferrous Met. Soc. China 16, 1228–1235 (2006)

Deng, Y.; Peng, B.; Xu, G.; Pan, Q.; Yin, Z.; Ye, R.; Wang, Y.; Lu, L.: Effects of Sc and Zr on mechanical property and microstructure of tungsten inert gas and friction stir welded aerospace high strength Al–Zn–Mg alloys. Mater. Sci. Eng. A 639, 500–513 (2015)

Huang, X.; Pan, Q.; Li, B.; Liu, Z.; Huang, Z.; Yin, Z.: Effect of minor Sc on microstructure and mechanical properties of Al–Zn–Mg–Zr alloy metal–inert gas welds. J. Alloy Compd. 629, 197–207 (2015)

Wu, L.M.; Wang, W.H.; Hsu, Y.F.; Trong, S.: Effects of homogenization treatment on recrystallization behavior and dispersoid distribution in an Al–Zn–Mg–Sc–Zr alloy. J. Alloy Compd. 456, 163–169 (2008)

Schöbel, M.; Pongratz, P.; Degischer, H.P.: Coherency loss of Al3(Sc, Zr) precipitates by deformation of an Al–Zn–Mg alloy. Acta Mater. 60, 4247–4254 (2012)

Robson, J.D.: A new model for prediction of dispersoid precipitation in aluminium alloys containing zirconium and scandium. Acta Mater. 52, 1409–1421 (2004)

Elagin, V.I.; Zakharov, V.V.; Rostova, T.D.: Scandium alloyed aluminum alloys. Metallovedenie i Termicheskaya Obrabotka Metallov 1, 24–28 (1992)

Tolley, A.; Radmilovic, V.; Dahmen, U.: Segregation in Al3(Sc, Zr) precipitates in Al–Sc–Zr alloys. Scr. Mater. 52, 621–625 (2005)

Lefebvre, W.; Danoix, F.; Hallem, H.; Forbord, B.; Bostel, A.; Marthinsen, K.: Precipitation kinetic of Al3(Sc, Zr) dispersoids in aluminium. J. Alloy Compd. 470, 107–110 (2009)

Hirano, K.; Fujikawa, S.: Impurity diffusion in aluminum. J Nucl. Mater. 69–70, 564–566 (1978)

Fujikawa, S.I.: Impurity diffusion of scandium in aluminium. Defect Diffus. Forum 143–147, 115–120 (1997)

Senkov, O.N.; Shagiev, M.R.; Senkova, S.V.; Miracle, D.B.: Precipitation of Al3(Sc, Zr) particles in an Al–Zn–Mg–Cu–Sc–Zr alloy during conventional solution heat treatment and its effect on tensile properties. Acta Mater. 56, 3723–3738 (2008)

Xiao, Q.F.; Huang, J.W.; Jiang, Y.G.; Jiang, F.Q.; Wu, Y.F.; Xu, G.F.: Effects of minor Sc and Zr additions on mechanical properties and microstructure evolution of Al−Zn−Mg−Cu alloys. Trans. Nonferrous Met. Soc. China 30, 1429–1438 (2020)

Vlach, M.; Cizek, J.; Kodetova, V.; Leibner, M.; Cieslar, M.; Harcuba, P.; Bajtosova, L.; Kudrnova, H.; Vlasak, T.; Neubert, V.; Cernoskova, E.; Kutalek, P.: Phase transformations in novel hot-deformed Al–Zn–Mg–Cu–Si–Mn–Fe (–Sc–Zr) alloys. Mater. Des. 193, 108821 (2020)

Deschamps, A.; Bley, F.; Livet, F.; Fabregue, D.; David, L.: In-situ small-angle X-ray scattering study of dynamic precipitation in an Al–Zn–Mg–Cu alloy. Philos. Mag. 83, 677–692 (2003)

Røyset, J.; Ryum, N.: Kinetics and mechanisms of precipitation in an Al–02 wt% Sc alloy. Mater. Sci. Eng. A 396, 409–422 (2005)

Forbord, B.; Lefebvre, W.; Danoix, F.; Hallem, H.; Marthinsen, K.: Three dimensional atom probe investigation on the formation of Al3(Sc, Zr)-dispersoids in aluminium alloys. Scr. Mater. 51, 333–337 (2004)

Lide, D.R.: Handbook of Chemistry and Physics, 75th edn. CRC Press, Cleveland (1995)

Lifshitz, I.M.; Slyozov, V.V.: The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 19, 35–50 (1961)

Kuehmann, C.J.; Voorhees, P.W.: Ostwald ripening in ternary alloys. Metall. Mater. Trans. A 27, 937–943 (1996)

Marquis, E.A.; Seidman, D.N.: Nannoscale structural evolution of Al3Sc precipitates in Al(Sc) alloys. Acta Mater. 49, 1909–1919 (2001)

Fuller, C.; Murray, J.; Seidman, D.: Temporal evolution of the nanostructure of Al(Sc, Zr) alloys: part I—chemical compositions of Al3(Sc1-χZrχ) precipitates. Acta Mater. 53, 5401–5413 (2005)

Liu, L.; Cui, X.Y.; Jiang, J.T.; Zhang, B.; Nomoto, K.; Zhen, L.; S.P. : Ringer, segregation of the major alloying elements to Al3(Sc, Zr) precipitates in an Al–Zn–Mg–Cu–Sc–Zr alloy. Mater. Charact. 157, 109898 (2019)

Acknowledgements

This work was financially supported by the National Key R&D Program of China (Nos. 2016YFB0300803 and 2016YFB0300903).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Xiong, B., Li, Z. et al. Precipitation Behavior of Al3(Sc,Zr) Particles in High-Alloyed Al–Zn–Mg–Cu–Zr–Sc Alloy During Homogenization. Arab J Sci Eng 46, 6027–6037 (2021). https://doi.org/10.1007/s13369-020-05268-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-05268-x