Abstract

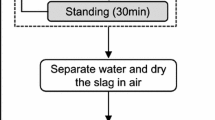

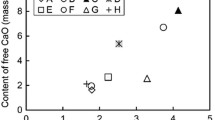

To recover degraded paddy fields, low-cost supplies of Ca, Si, and Fe are necessary. Steelmaking slag contains these three elements, which makes it a potential material for amending paddy soil. To simultaneously supply Ca, Si, and Fe to paddy field, the optimum slag chemistry as a fertilizer was found in our previous study to have a basicity of about 1.6 and FeO concentration of about 25 mass%, referring to the CaO–SiO2–FeO system. The optimum slag structure, which is the coexistence of the CaO–SiO2–FeO glassy phase and 2CaO·SiO2 soil solution, can be obtained by quenching the molten slag from 1573 K. In this study, to evaluate the effects of the above novel slag fertilizer on soil amendment, a column test using an actual paddy soil was conducted. During the 2 months of testing, the concentrations of Fe, Ca, and Si in the soil solution were increased by applying the novel fertilizer, compared to two commercial fertilizers made of steelmaking slag. From the soil analysis before and after the column test, the concentrations of easily reducible iron oxide, exchangeable Ca, and adsorbed silica of the paddy were also increased by the novel slag fertilizer. In addition, a model for predicting the time-dependent changes in soil conditions was established using PHREEQC software. This model effectively estimated the daily changes in pH, oxidation and reduction potential, and the concentrations of each element in the soil solution.

Graphical Abstract

Similar content being viewed by others

References

Yamashita K, Komiyama T, Nizuma S (2012) Research and utilization of silicate in agriculture in recent years, 3. History of development of silicate materials and current status of utilization in the field. Jpn J Soil Sci Plant Nutr 83:613–619 (in Japanese)

Ito K (2014) Steelmaking slag for fertilizer usage. Nippon Steel Sumitomo Met Tech Rep 399:132–138 (in Japanese)

Gao X, Okubo M, Maruoka N, Shibata H, Ito T, Kitamura S (2015) Production and utilization of iron and steelmaking slag in Japan and the application of steelmaking slag for the recovery of paddy fields damaged by tsunami. Trans Inst Min Metall C 124:116–124

Gao X, Kim S-j, Minoshima H, Ito T, Kitamura S (2017) Effect of the mineralogical phases in steelmaking slag fertilizer on the dissolution behavior of nutritious elements and rice growth. J Sustain Metall 3:207–218

Gao X, Ito T, Nasukawa H, Kitamura S (2016) Application of fertilizer made of steelmaking slag in the recovery of paddy fields damaged by the tsunami of 2011. ISIJ Inter 56:1103–1110

Maruoka N, Okubo M, Shibata H, Gao X, Ito T, Kitamura S (2015) Improvement of desalted paddy soil by the application of fertilizer made of steelmaking slag (Recovery of a Paddy field damaged by the tsunami using fertilizer made of steelmaking slag-1). Tetsu-to-Hagané 101:445–456 (in Japanese)

Gao X, Maruoka N, Kim S-j, Ueda S, Kitamura S (2015) Dissolution behavior of nutrient elements from fertilizer made of steelmaking slag under the environment of paddy field after irrigation. J Sustain Metal 1:304–313

Koizumi S, Gao X, Ueda S, Kitamura S (2019) Dissolution behavior of Fe from CaO-SiO2-FeOx glassy phase. Tetsu-to-Hagané 105:664–673 (in Japanese)

Koizumi S, Gao X, Ueda S, Kitamura S (2017) Dissolution behavior of Fe from glassy oxide phase in steelmaking slag. In: Proceedings of the 8th International Symposium on High Temperature Metallurgical Processing, TMS, Pittsburgh, USA, pp 395–401

Koizumi S, Gao X, Sukenaga S, Kanehashi K, Takahashi T, Ueda S, Kitamura S (2020) The influence of glass structure on the dissolution behavior of Fe from glassy slag in CaO-SiO2-FeOx system. J Sustain Metal (under review)

Koizumi S, Gao X, Ueda S, Kitamura S, Kanehashi K, Takahashi T (2018) The influence of glass structure on the dissolution behavior from glassy slag in CaO-SiO2-FeOx system. CAMP ISIJ 31:180 (in Japanese)

Koizumi S, Gao X, Ueda S, Kitamura S (2019) Dissolution behavior of slag coexisting of 2CaO·SiO2 phase with glassy phase of CaO-SiO2-FeOx system. CAMP ISIJ 32:187 (in Japanese)

Koizumi S, Gao X, Ueda S, Kitamura S (2020) Design of a novel fertilizer made of steelmaking slag using the glassy phase of the CaO–SiO2–FeO system. Part I: Optimization on the slag chemistry and microstructure. J Sustain Metal. https://doi.org/10.1007/s40831-020-00320-4

Kimura M, Nanjyo M (2018) Introduction of soil science, 2nd edn. Buneido Shuppann, Tokyo (in Japanese)

Yamane I (1982) Science of paddy soil. Nousanngyoson Bunkakyokai, Tokyo (in Japanese)

United States Geological Survey (2019) PHREEQC Version 3, https://www.usgs.gov/software/phreeqc-version-3 Accessed 06 Dec, 2019

Editorial Committee on the Analysis Method of Soil Environment (1997) The analysis method of soil environment. Editorial Committee on the Analysis Method of Soil Environment, Hakuyuusha (in Japanese)

Kamewada K (2001) Development of easy method for CEC measurement. J Jpn Soc Soil Sci Plant Nutr 72:550–553 (in Japanese)

Skjemstad JO, Gillman GP, Massis A, Spouncer LR (2008) Measurement of cation exchange capacity of organic-matter fraction form soils using a modified compulsive exchange method. Commun Soil Sci Plant Anal 39:926–937

Dohrmann T, Kaufhold S (2009) Three new, quick CEC methods for determining the amounts of exchangeable calcium cations in calcareous clays. Clays Clay Miner 57:338–352

Shiga H, Ooyama N, Suzuki M (1983) Factors causing abnormal spikes in paddy rice in double-cropping paddy field. J Jpn Soc Soil Sci Plant Nutr 54:383–388 (in Japanese)

Yamauchi M (1997) Rice crop establishment in flooded soil. J Jpn Soc Soil Sci Plant Nutr 68:467–476 (in Japanese)

Inubushi K, Wada H, Takai Y (2012) Easily decomposable organic matter in paddy soil. Soil Science and Plant Nutrition 30:189–198

Shinozak H (2008) Enchiridion of fertilizer, 6th edn. Rural Culture Association Japan, Tokyo (in Japanese)

Osozawa S, Kubota T, Miyazaki T, Nakano M (1989) Mass transfer in soil (8)—change and transfer of gaseous element in soil. J Agric Eng Soc Jpn 57:135–142 (in Japanese)

Toyoda K (2018) Soil microbiology. Asakura Publication, Tokyo (in Japanese)

Takai Y, Kamura T (1966) The mechanism of reduction in waterlogged paddy soil. Folia Microbiol 11:304–313

Gotoh S, Yamashita K (1966) Oxidation-reduction potentials of a paddy soil in in situ with special reference to the production of ferrous ikon, manganous manganese and sulfide. Soil Science and Plant Ntrition 12:24–32

Ishi S, Ikeda S, Minamisawa K, Senoo K (2011) Nitrogen cycling in rice paddy environments: past achievements and future challenges. Microbes Environ 26:282–292

Kamura T, Takai Y, Isihkawa K (1963) Microbial reduction mechanism of ferric iron in paddy soils (Part I). Soil Sci Plant Nutr 9:5–9

Kirk G (2004) The biogeochemistry of submerged soils. Wiley, New York

Horikoshi H (1962) Alkalophilic microorganisms. Kagaku to Seibutsu 24:523–531 (in Japanese)

Ministry of Agriculture, Forestry and Fisheries, Japan (2008) Basic Guidelines to enhance fertility of soil. http://www.maff.go.jp/j/seisan/kankyo/hozen_type/h_dozyo/pdf/chi4.pdf. Accessed 26 May, 2020

Essington ME (2015) Soil and water chemistry, 2nd edn. CRC Press, Boca Raton

Hingston FJ, Atokinson RJ, Posner AM, Quirk JP (1967) Specific adsorption of anions. Nature 215:1459–1461

Jones LHP, Handreck KA (1963) Effects of iron and aluminium oxides on silica in solution in soils. Nature 198:852–853

Beckwith RS, Reeve R (1963) Studies on soluble silica in soils. I. The sorption of silicic acid by soils and minerals. Aust J Soil Res 1:157–168

Beckwith RS, Reeve R (1964) Studies on soluble silica in soils. II. The release of monosilicic acid from soils. Aust J Soil Res 2:33–45

Appelo CAJ, Postma D (2004) Geochemistry, groundwater and pollution, 2nd edn. CRC Press, Boca Raton

Nakano M, Miyazaki T (1989) Mass transfer in soil (7)—prediction of degradation of coarse organic substances in soil. J Agric Eng Soc Jpn 57:47–52 (in Japanese)

Inoko A (1978) Decomposition and accumulation of organic matter in soil. Its approach to formulating. J Jpn Soc Soil Sci Plant Nutr 52:548–558 (in Japanese)

Maeda K, Shiga H (1978) Decomposition process of various organic materials under paddy conditions. J Jpn Soc Soil Sci Plant Nutr 49:455–460 (in Japanese)

Bolt GH, Bruggenwert MGM (1980) Soil chemistry A—basic elements, 2nd ed., (Iwata S, Miwa Y, Inoue T, Minami K. Trans.) Japan Scientific Societies Press, Tokyo, Japan (Original work published 1976 by Elsevier, New York)

Sadana US, Chahal DS (1995) Iron availability, electrochemical changes and nutrient content of rice as influenced by green manuring in a submerged soil. In: Iron nutrition in soil and plants: proceedings of the 7th international symposium on iron nutrition and interactions in plants, Kluwer Academic Publishers, Spain, pp.105–109

Appelo CAJ, Postma D (1993) Geochemistry, groundwater and pollution. Balkema, Rotterdam

Ludwig B, Kolbl A (2002) Modelling cation exchange in columns of disturbed and undisturbed subsoil. Eur J Soil Sci 53:645–654

Tournassat C, Gailhanou H, Crouzet C, Braibant G, Gautier A, Lassin A, Blanc P, Gaucher EC (2007) Two cation exchange models for direct and inverse modelling of solution major cation composition in equilibrium with illite surfaces. Geochim Cosmochim Acta 71:1098–1114

Yoshida M, Ito N (1974) The composition of exchangeable cation in paddy soil and acidification of soil be oxidation. J Jpn Soc Soil Sci Plant Nutr 45:525–528 (in Japanese)

Jintoku T, Shibata M, Yoshida Y, Suyama T (2003) Sorption modeling study in the OECD/NEA sorption project. JNC Tech Rev 21:65–77 (in Japanese)

Acknowledgements

The authors gratefully acknowledge the financial support provided by the Nippon Slag Association and Interdepartmental Doctoral Degree Program for Multi-dimensional Materials Science Leaders, Tohoku University. The authors also thank Professor Hiroyuki Shibata and Hongmin Zhu of Tohoku University for their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Hiromichi Takebe.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Koizumi, S., Gao, X., Ueda, S. et al. Design of a Novel Fertilizer Made from Steelmaking Slag Using the Glassy Phase of the CaO–SiO2–FeO System. Part II: Evaluation of the Novel Fertilizer in a Paddy Soil Environment. J. Sustain. Metall. 7, 99–114 (2021). https://doi.org/10.1007/s40831-020-00315-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-020-00315-1