Abstract

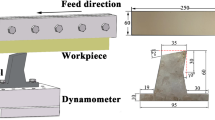

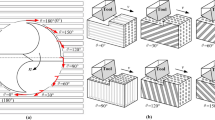

Wood fiber/polyethylene composite (WFPEC) is composed of a natural wood fiber and a recyclable polyethylene plastic, which is normally used as an environmental protection composite material. However, better knowledge of chip formation and surface damage mechanism of WFPEC is essential to improve its machinability for extending exterior and interior applications. In this article, machinability of WFPEC was investigated by analyzing the disparity between cutting efficiency and surface quality through a group of orthogonal cutting experiments with change of cutting depth. The chip formation process was recorded by a high-speed camera system with 5000 frames per second. Surface topography was observed by a scanning electron microscope. The results showed that the chip morphology changed from continuous cutting governed by a continuous shearing process under the shallow cutting depth, to a discontinuous cutting governed by plastic fracture under the deep cutting depth ahead of the tool tip. Flattened matrix was the main form of surface topography caused by shallow cutting depth, while matrix-fiber tearing was caused by deep cutting depth. Pullout/fracture and debonding of fibers were related to the fiber orientation angle and the diameter of fiber bundles, but not to the cutting depth. Taken together, the toughness of the workpiece material in the cutting region decreased with the increase in cutting depth. To avoid matrix-fiber tearing, shallow cutting depth should be used during finishing to maintain surface quality. In contrast, pre-cutting can be performed with a deep cutting depth in order to improve the cutting efficiency.

Similar content being viewed by others

Code availability

Not applicable.

References

Adamovskyi AA, Kostenko AD (2019) The friction coefficient of natural diamond against materials based on cubic boron nitride. J Superhard Mater 41:281–282

Bachrathy D, Stepan G (2017) Cutting force measurements in high speed milling: extension of the frequency range of Kistler dynamometer. In: Proceedings of the 39th international MATADOR conference on advanced manufacturing, No. 0033

Bazant P, Munster L, Machovsky M, Sedlak J, Pastorek M, Kozakova Z, Kuritka I (2014) Wood flour modified by hierarchical Ag/ZnO as potential filler for wood–plastic composites with enhanced surface antibacterial performance. Ind Crops Prod 62:179–187. https://doi.org/10.1016/j.indcrop.2014.08.028

Chowdhury S, de Barra E, Laugier MT (2005) Hardness measurement of CVD diamond coatings on SiC substrates. Surf Coat Technol 193:200–205

Davis B, Dabrow D, Ju LC, Li AH, Xu CY, Huang Y (2017) Study of Chip Morphology and Chip Formation Mechanism During Machining of Magnesium-Based Metal Matrix Composites. J Manuf Sci Eng 139:091008–1

Fowler PA, Hughes JM, Elias RM (2006) Biocomposites: technology, environmental credentials and market forces. J Sci Food Agr 86:1781–1789

Gao YF, Ge PQ, Zhang L, Bi WB (2019) Material removal and surface generation mechanisms in diamond wire sawing of silicon crystal. Mat Sci Semicon Proc 103:104642

Guo XL, Ekevad M, Marklund B, Li RR, Cao PX, Grönlund A (2014) Cutting forces and chip morphology during wood plastic composites orthogonal cutting. BioResources 9:2090–2106

Guo XL, Li RR, Cao PX, Ekevad M, Cristovao L, Marklund B, Gronlund A (2015) Effect of average chip thickness and cutting speed on cutting forces and surface roughness during peripheral up milling of wood flour/polyvinyl chloride composite. Wood Res 60:147–156

Kilinc K, Kanbur Y, Tayfun U (2019) Mechanical, thermo-mechanical and water uptake performance of wood flour filled polyurethane elastomer eco-composites: influence of surface treatment of wood flour. Holzforschung 73:401–407. https://doi.org/10.1515/hf-2018-0116

Komanduri R, Von Turkovich BF (1981) New observations on the mechanism of chip formation when machining titanium alloys. Wear 69:179–188. https://doi.org/10.1016/0043-1648(81)90242-8

Kuzu AT, Bakkal M (2016) The effect of cutting parameters and tool geometry on machinability of cotton-fiber reinforced polymer composites: cutting forces, burr formation, and chip morphology. J Ind Text 45:1364–1382

Lin Z, Renneckar S (2011) Nanocomposite-based lignocellulosic fibers 2: layer-by-layer modification of wood fibers for reinforcement in thermoplastic composites. Compos A Appl Sci Manuf 42:84–91. https://doi.org/10.1016/j.compositesa.2010.10.011

Madhavan V, Lipczynski G, Lane B, Whitenton E (2015) Fiber orientation angle effects in machining of unidirectional CFRP laminated composites. J Manuf Process 20:431–442

Nairn JA (2016) Numerical modelling of orthogonal cutting: application to woodworking with a bench plane. Interface Focus 6:ARTN20150110. https://doi.org/10.1098/rsfs.2015.0110

Pelaez-Samaniego MR, Yadama V, Lowell E, Espinoza-Herrera R (2013) A review of wood thermal pretreatments to improve wood composite properties. Wood Sci Technol 47:1285–1319. https://doi.org/10.1007/s00226-013-0574-3

Saloni D, Buehlmann U, Lemaster RL (2011) Tool wear when cutting wood fiber-plastic composite materials. For Prod J 61:149–154

Thibaut B (1988) Le processus de coupe du bois par déroulage. Thèse d’état, Université Montpellier (The process of cutting wood by peeling, PhD thesis, Montpellier University)

Thibaut B, Denaud L, Collet R et al (2016) Wood machining with a focus on French research in the last 50 years. Ann For Sci 73:163–184

Vyas A, Shaw MC (1999) Mechanics of saw-tooth chip formation in metal cutting. J Manuf Sci Eng 121:163–172. https://doi.org/10.1115/1.2831200

Wei W, Li Y, Xue T et al (2018) The research progress of machining mechanisms in milling wood-based materials. BioResources 13:2139–2149. https://doi.org/10.15376/biores.13.1.Wei

Wyeth DJ, Goli G, Atkins AG (2009) Fracture toughness, chip types and the mechanics of cutting wood: a review COST Action E35 2004–2008: Wood machining—micromechanics and fracture. Holzforschung 63:168–180

Acknowledgements

The authors are grateful for the support from the National Science Foundation of China (31971594), Leitz Tooling System Co., Ltd., for supplying the samples of PCD tools, and Guofeng Wood Plastic Composite Co., Ltd., for supplying the samples of wood fiber/polyethylene composite.

Funding

This study was funded by the National Natural Science Foundation of China (31971594).

Author information

Authors and Affiliations

Contributions

Xiaolei Guo contributed to project administration, experimental design, analysis and discussion of the data, and writing the paper. Jinxin Wang was involved in laboratory experiments, data collection, analysis and discussion of the data, and editing the paper. Dietrich Buck contributed to laboratory experiments, data collection, and review of the paper. Zhaolong Zhu was involved in laboratory experiments, data collection, and supervision of the work. Yong Guo contributed to experimental design, laboratory experiments, and supervision of the work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Availability of data and material (data transparency)

The datasets generated and analyzed during the current study are available from the corresponding author on request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, X., Wang, J., Buck, D. et al. Machinability of wood fiber/polyethylene composite during orthogonal cutting. Wood Sci Technol 55, 521–534 (2021). https://doi.org/10.1007/s00226-020-01256-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-020-01256-4