Abstract

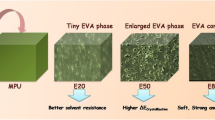

Binary and ternary systems of HDPE/EVA with amorphous nanotalc contents of 1% m/m were prepared by mixing the components in the molten state in a twin-screw extruder followed by injection molding. The thermal properties were investigated by thermogravimetric analysis (TGA) and by differential scanning calorimetry (DSC) and showed that the thermal stability of the nanocomposites was slightly improved with nanotalc incorporation. The morphology of the nanocomposites, investigated by scanning electron microscopy (SEM), revealed a good dispersion of the nanotalc layers within the polymer matrix, and changes of the morphology from sea-island to co-continuous as a function of the composition, as well as refinement of the size of EVA phase. The dynamic mechanical properties of the samples showed that the storage modulus increased with a diffuse pattern with the addition of the nanotalc, while the tan δ curve showed an intense peak for the 50EVA/NTA nanocomposite at the Tg of EVA. The mechanical properties of nanocomposites were studied by tensile and impact tests. A remarkable behavior was verified for the 50EVA/NTA nanocomposite, which manifested a characteristic of super ductility and high damping capacity, showing that the amorphous nanotalc can be used as a high-performance filler to improve the ductility of polymeric systems.

Similar content being viewed by others

References

Hemlata MSN (2015) Mechanical, morphological, and thermal properties of nanotalc reinforced PA6/SEBS-g-MA composites. J Appl Polym Sci 132:1–10. https://doi.org/10.1002/app.41381

Chow WS, Mohd Ishak ZA (2015) Polyamide blend-based nanocomposites: A review. Express Polym Lett 9:211–232. https://doi.org/10.3144/expresspolymlett.2015.22

Gupta B, Lacrampe MF, Krawczak P (2006) Polyamide-6/clay nanocomposites: A critical review. Polym Polym Compos 14:13–38. https://doi.org/10.1177/096739110601400102

Dias G, Prado M, Le Roux C et al (2018) Analyzing the influence of different synthetic talcs in waterborne polyurethane nanocomposites obtainment. J Appl Polym Sci 135:1–8. https://doi.org/10.1002/app.46107

Norouzi M, Zare Y, Kiany P (2015) Nanoparticles as effective flame retardants for natural and synthetic textile polymers: Application, mechanism, and optimization. Polym Rev 55:531–560. https://doi.org/10.1080/15583724.2014.980427

Zare Y, Garmabi H (2012) Nonisothermal crystallization and melting behavior of PP/nanoclay/CaCO3 ternary nanocomposite. J Appl Polym Sci 124:1225–1233. https://doi.org/10.1002/app.35134

Vladuta C, Voinea M, Purghel E, Duta A (2009) Correlations between the structure and the morphology of PET-rubber nanocomposites with different additives. Mater Sci Eng B Solid-State Mater Adv Technol 165:221–226. https://doi.org/10.1016/j.mseb.2009.07.004

Zare Y (2016) Study on interfacial properties in polymer blend ternary nanocomposites: Role of nanofiller content. Comput Mater Sci 111:334–338. https://doi.org/10.1016/j.commatsci.2015.09.053

Zhu YJ, Ma YQ (2003) Phase separation of a polymer blend driven by oscillating particles. Phys Rev E - Stat Nonlinear, Soft Matter Phys 67:415031–415037. https://doi.org/10.1103/PhysRevE.67.041503

Mallick S, Khatua BB (2011) Morphology and properties of nylon6 and high density polyethylene blends in absence and presence of nanoclay. J Appl Polym Sci. https://doi.org/10.1002/app.33580

Pötschke P, Paul DR (2003) Formation of co-continuous structures in melt-mixed immiscible polymer blends. J Macromol Sci - Polym Rev 43:87–141

Zhou YG, Su B, Turng LS (2016) Fabrication of super-ductile PP/LDPE blended parts with a chemical blowing agent. J Appl Polym Sci 133:1–16. https://doi.org/10.1002/app.44101

Yuan Q, Shah JS, Bertrand KJ, Misra RDK (2009) On processing and impact deformation behavior of high density polyethylene (HDPE)-calcium carbonate nanocomposites. Macromol Mater Eng 294:141–151. https://doi.org/10.1002/mame.200800300

Chen Y, Zou H, Liang M, Cao Y (2014) Melting and crystallization behavior of partially miscible high density polyethylene/ethylene vinyl acetate copolymer (HDPE/EVA) blends. Thermochim Acta 586:1–8. https://doi.org/10.1016/j.tca.2014.04.007

Moreira ACF, Cario Júnior FO, Soares BG (2002) Morfologia Co-Contínua na Mistura Poliestireno/Copolímero de Etileno-Acetato de Vinila. Polímeros 12:138–146. https://doi.org/10.1590/s0104-14282002000300005

Alothman OY (2012) Processing and characterization of high density polyethylene/ethylene vinyl acetate blends with different VA contents. Adv Mater Sci Eng. https://doi.org/10.1155/2012/635693

Cui L, Ma X, Paul DR (2007) Morphology and properties of nanocomposites formed from ethylene-vinyl acetate copolymers and organoclays. Polymer (Guildf) 48:6325–6339. https://doi.org/10.1016/j.polymer.2007.08.040

Dumas A, Mizrahi M, Martin F, Requejo FG (2015) Local and Extended-Order Evolution of Synthetic Talc during Hydrothermal Synthesis: Extended X-ray Absorption Fine Structure, X-ray Diffraction, and Fourier Transform Infrared Spectroscopy Studies. Cryst Growth Des 15:5451–5463. https://doi.org/10.1021/acs.cgd.5b01076

Claverie M, Dumas A, Carême C et al (2018) Synthetic Talc and Talc-Like Structures: Preparation, Features and Applications. Chem - A Eur J 24:519–542. https://doi.org/10.1002/chem.201702763

Dumas A, Martin F, Le Roux C et al (2013) Phyllosilicates synthesis: A way of accessing edges contributions in NMR and FTIR spectroscopies. Example of synthetic talc. Phys Chem Miner 40:361–373. https://doi.org/10.1007/s00269-013-0577-5

Mehrjerdi AK, Adl-Zarrabi B, Cho SW, Skrifvars M (2013) Mechanical and thermo-physical properties of high-density polyethylene modified with talc. J Appl Polym Sci 129:2128–2138. https://doi.org/10.1002/app.38945

Yousfi M, Livi S, Dumas A et al (2013) Use of new synthetic talc as reinforcing nanofillers for polypropylene and polyamide 6 systems: Thermal and mechanical properties. J Colloid Interface Sci 403:29–42. https://doi.org/10.1016/j.jcis.2013.04.019

Dias G, Prado M, Ligabue R et al (2018) Synthetic talc as a new platform for producing fluorescent clay polyurethane nanocomposites. Appl Clay Sci. https://doi.org/10.1016/j.clay.2018.03.012

Fiorentino B, Fulchiron R, Bounor-Legaré V et al (2015) Chemical modification routes of synthetic talc: Influence on its nucleating power and on its dispersion state. Appl Clay Sci 109–110:107–118. https://doi.org/10.1016/j.clay.2015.02.026

González I, Eguiazábal JI, Nazábal J (2006) Rubber-toughened polyamide 6/clay nanocomposites. Compos Sci Technol 66:1833–1843. https://doi.org/10.1016/j.compscitech.2005.10.008

Ray SS (2014) Recent trends and future outlooks in the field of clay-containing polymer nanocomposites. Macromol Chem Phys 215:1162–1179. https://doi.org/10.1002/macp.201400069

Balamurugan GP, Maiti SN (2010) Effects of nanotalc inclusion on mechanical, microstructural, melt shear rheological, and crystallization behavior of polyamide 6-based binary and ternary nanocomposites. Polym Eng Sci 50:1978–1993. https://doi.org/10.1002/pen.21724

Dumas A, Martin F, Ferrage E et al (2013) Synthetic talc advances: Coming closer to nature, added value, and industrial requirements. Appl Clay Sci 85:8–18. https://doi.org/10.1016/j.clay.2013.09.006

Wunderlich B (1976) Macromolecular Physics, 1st edn. Academic Press, New York

ASTM-D638–14 (2014) Standard Test Method for Tensile Properties of Plastics. ASTM Stand

ASTM-D256-18 (2018) Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics 1. Astm D256. https://doi.org/10.1520/D0256-10R18

Ferrage E, Martin F, Boudet A et al (2002) Talc as nucleating agent of polypropylene: Morphology induced by lamellar particles addition and interface mineral-matrix modelization. J Mater Sci 37:1561–1573. https://doi.org/10.1023/A:1014929121367

Sánchez-Soto PJ, Wiewióra A, Avilés MA et al (1997) Talc from Puebla de Lillo, Spain. II. Effect of dry grinding on particle size and shape. Appl Clay Sci 12:297–312. https://doi.org/10.1016/S0169-1317(97)00013-6

Dikobe DG, Luyt AS (2009) Morphology and properties of polypropylene/ethylene vinyl acetate copolymer/wood powder blend composites. Express Polym Lett 3:190–199. https://doi.org/10.3144/expresspolymlett.2009.24

Wang Y, Na B, Fu Q (2003) Super polyolefin blends achieved via dynamic packing injection molding: Morphology and properties. Chinese J Polym Sci English Ed 21:505–514

Mehrabzadeh M, Kamal MR (2004) Melt processing of PA-66/clay, HDPE/clay and HDPE/PA-66/clay nanocomposites. Polym Eng Sci 44:1152–1161. https://doi.org/10.1002/pen.20108

Lee S, Kim M, Song HY, Hyun K (2019) Characterization of the Effect of Clay on Morphological Evaluations of PLA/Biodegradable Polymer Blends by FT-Rheology. Macromolecules 52:7904–7919. https://doi.org/10.1021/acs.macromol.9b00800

Komalan C, George KE, Kumar PAS et al (2007) Dynamic mechanical analysis of binary and ternary polymer blends based on nylon copolymer/EPDM rubber and EPM grafted maleic anhydride compatibilizer. Express Polym Lett 1:641–653. https://doi.org/10.3144/expresspolymlett.2007.88

Huang NH, Chen ZJ, Yi CH, Wang JQ (2010) Synergistic flame retardant effects between sepiolite and magnesium hydroxide in ethylene-vinyl acetate (EVA) matrix. Express Polym Lett 4:227–233. https://doi.org/10.3144/expresspolymlett.2010.29

Padhi S, Achary PGR, Nayak NC (2017) Mechanical and morphological properties of halloysite nanotubes filled ethylene-vinyl acetate copolymer nanocomposites. Indian J Chem Technol 24:184–191. https://doi.org/10.1515/nano.0036.00085

Hull TR, Price D, Liu Y et al (2003) An investigation into the decomposition and burning behaviour of Ethylene-vinyl acetate copolymer nanocomposite materials. Polym Degrad Stab 82:365–371. https://doi.org/10.1016/S0141-3910(03)00214-3

Gilman JW, Jackson CL, Morgan AB et al (2000) Flammability Properties of Polymer−Layered-Silicate Nanocomposites. Polypropylene and Polystyrene Nanocomposites. Chem Mater 12:1866–1873. https://doi.org/10.1021/cm0001760

Krook M, Gällstedt M, Hedenqvist MS (2005) A study on montmorillonite/polyethylene nanocomposite extrusion-coated paperboard. Packag Technol Sci 18:11–20. https://doi.org/10.1002/pts.670

Liao CZ, Tjong SC (2013) Mechanical and thermal performance of high-density polyethylene/alumina nanocomposites. J Macromol Sci Part B Phys 52:812–825. https://doi.org/10.1080/00222348.2012.733297

Hadal RS, Misra RDK (2004) The influence of loading rate and concurrent microstructural evolution in micrometric talc- and wollastonite-reinforced high isotactic polypropylene composites. Mater Sci Eng A 374:374–389. https://doi.org/10.1016/j.msea.2004.03.035

Makhlouf A, Satha H, Frihi D et al (2016) Optimization of the crystallinity of polypropylene/submicronic-talc composites: The role of filler ratio and cooling rate. Express Polym Lett 10:237–247. https://doi.org/10.3144/expresspolymlett.2016.22

Karrad S, Lopez Cuesta JM, Crespy A (1998) Influence of a fine talc on the properties of composites with high density polyethylene and polyethylene/polystyrene blends. J Mater Sci 33:453–461. https://doi.org/10.1023/A:1004392318226

Rybnikář F (1989) Orientation in composite of polypropylene and talc. J Appl Polym Sci 38:1479–1490. https://doi.org/10.1002/app.1989.070380806

Sinha Ray S, Okamoto M (2003) Polymer/layered silicate nanocomposites: A review from preparation to processing. Prog Polym Sci 28:1539–1641. https://doi.org/10.1016/j.progpolymsci.2003.08.002

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: Preparation, properties and uses of a new class of materials. Mater Sci Eng R Reports 28:1–63. https://doi.org/10.1016/S0927-796X(00)00012-7

Sewda K, Maiti SN (2013) Dynamic mechanical properties of high density polyethylene and teak wood flour composites. Polym Bull 70:2657–2674. https://doi.org/10.1007/s00289-013-0941-0

Savini G, Oréfice RL (2017) Toughening high density polyethylene submitted to extreme ambient temperatures. J Polym Res 24:1–11. https://doi.org/10.1007/s10965-017-1243-2

John B, Varughese KT, Oommen Z et al (2003) Dynamic mechanical behavior of high-density polyethylene/ethylene vinyl acetate copolymer blends: The effects of the blend ratio, reactive compatibilization, and dynamic vulcanization. J Appl Polym Sci 87:2083–2099. https://doi.org/10.1002/app.11458

Kuila T, Khanra P, Mishra AK et al (2012) Functionalized-graphene/ethylene vinyl acetate co-polymer composites for improved mechanical and thermal properties. Polym Test 31:282–289. https://doi.org/10.1016/j.polymertesting.2011.12.003

Guimarães MJOC, Rocha MCG, Coutinho FMB (2002) Polietileno de Alta Densidade Tenacificado com Elastômero Metalocênico: 1. Propriedades Mecânicas e Características Morfológicas Polímeros 12:76–84. https://doi.org/10.1590/s0104-14282002000200006

Joseph S, Focke WW (2016) Polyvinyl Alcohol-Modified Pithecellobium Clypearia Benth Herbal Residue Fiber Polypropylene Composites. Polym Compos 37:915–924. https://doi.org/10.1002/pc.23250

Xiang F, Wu J, Liu L et al (2011) Largely enhanced ductility of immiscible high density polyethylene/polyamide 6 blends via nano-bridge effect of functionalized multiwalled carbon nanotubes. Polym Adv Technol 22:2533–2542. https://doi.org/10.1002/pat.1796

Sánchez-Valdes S, Méndez-Nonell J, Medellín-Rodríguez FJ et al (2009) Effect of PEgMA/amine silane compatibilizer on clay dispersion of polyethylene-clay nanocomposites. Polym Bull 63:921–933. https://doi.org/10.1007/s00289-009-0170-8

Acknowledgments

The authors acknowledge the financial support from CNPq, CAPES and FAPEMIG.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Savini, G., Oréfice, R.L. Super ductility in HDPE/EVA blends triggered by synthetic amorphous nanotalc. J Polym Res 28, 19 (2021). https://doi.org/10.1007/s10965-020-02389-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02389-7