Abstract

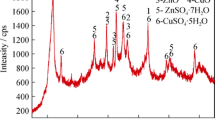

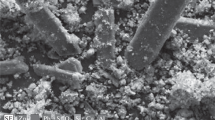

In this study, hydrometallurgical processes involving pressure acid leaching and solvent extraction were developed to aid recovery of indium from zinc slag, which is produced in the imperial smelting process. Four different acid leaching methods were studied, namely atmospheric leaching, atmospheric leaching with KMnO4, roasting-atmospheric leaching, and oxygen pressure leaching in a sulfuric acid medium. Oxygen pressure acid leaching is the most effective method for indium extraction, and 94.1% of indium was leached under the optimum conditions, i.e., 300 g/L H2SO4,oxygen pressure 0.4 MPa, liquid/solid ratio 10 mL/g, and temperature 100°C for 5 h. X-ray diffraction and scanning electron microscopy examination of the raw material and leaching residue samples indicated that the intermetallic compounds Cu5Zn8and Cu2Zn, metallic zinc, and iron in the raw material dissolved, leaving the insoluble components PbSO4 and Pb as the major compounds in the leaching residue. A 98.5% proportion of the indium in the leaching solution was selectively extracted with 30% bis(2-ethylhexyl) phosphate and 70% kerosene by three-stage counter-current extraction, and 99.5% of the indium in the loaded organic phase was stripped by 6 mol/L HCl through four-stage counter-current stripping. The overall recovery yield of indium through all processes was approximately 92%.

Similar content being viewed by others

References

N.J. Cook, C.L. Ciobanuand, and T. Willuams, N.J. Cook, C.L. Ciobanuand, and T. Willuams, Hydrometallurgy 108, 226. (2011).

S. Wegscheider, S. Steinlechner, and M. Leuchtenmuller, S. Wegscheider, S. Steinlechner, and M. Leuchtenmuller, JOM 69, 388. (2017).

Y. Fan, Y. Liu, L. Niu, T. Jing, W. Zhang, and T. Zhang, Y. Fan, Y. Liu, L. Niu, T. Jing, W. Zhang, and T. Zhang, Hydrometallurgy 186, 192. (2019).

J.W. Han, W. Li, W.Q. Qin, F. Jiao, D.W. Wang, and C. Liang, J.W. Han, W. Li, W.Q. Qin, F. Jiao, D.W. Wang, and C. Liang, JOM 68, 2543. (2016).

F. Zhang, C. Wei, Z. Deng, X. Li, C. Li, and M. Li, F. Zhang, C. Wei, Z. Deng, X. Li, C. Li, and M. Li, Hydrometallurgy 161, 102. (2016).

B. Nikov, P. Stojanov, and T. Stojadinovic, B. Nikov, P. Stojanov, and T. Stojadinovic, Hydrometallurgy 94, 1153. (1994).

S. Li, Y. Liu, D. Zhai, and X. Zhou, S. Li, Y. Liu, D. Zhai, and X. Zhou, J. Kunming Inst. Technol. 19, 38. (in Chinese) (1994).

B. Yang, Y.N. Dai, and W. Luo, B. Yang, Y.N. Dai, and W. Luo, J. Kunming Univ. Sci. Technol. 23, 1. (in Chinese) (1998).

M. Hu, B. Peng, L.Y. Chai, Y.C. Li, N. Peng, and Y.Z. Yuan, M. Hu, B. Peng, L.Y. Chai, Y.C. Li, N. Peng, and Y.Z. Yuan, and D. Chen, JOM 67, 2005. (2015).

X. Dai, M. Yang, K. Chen, P. Zeng, Y. Li, and M. Huang, X. Dai, M. Yang, K. Chen, P. Zeng, Y. Li, and M. Huang, Hydrometall. China 34, 394. (in Chinese) (2015).

Z. Lan, Z. Lan, Nonferrous Metals 5, 33. (in Chinese) (2003).

X. Li, and J. Yao, X. Li, and J. Yao, Metal Mine 3, 40. (in Chinese) (2007).

Y. Liang, C. Wei, P. Jiang, M. Li, C. Li, Z. Deng, and G. Wang, Y. Liang, C. Wei, P. Jiang, M. Li, C. Li, Z. Deng, and G. Wang, Nonferrous Metals 62, 69. (in Chinese) (2010).

Y. Li, V.G. Papangelakis, and I. Perederiy, Y. Li, V.G. Papangelakis, and I. Perederiy, Hydrometallurgy 97, 185. (2009).

X. Li, Y. Zhang, Q. Qin, J. Yang, and Y. Wei, X. Li, Y. Zhang, Q. Qin, J. Yang, and Y. Wei, Trans. Nonferrous Met. Soc. China 20, s141. (2010).

LangováŠárka, and Matýsek, D. Hydrometallurgy 101, 171 (2010)

A. Muszer, J. Wódka, T. Chmielewski, and S. Matuska, A. Muszer, J. Wódka, T. Chmielewski, and S. Matuska, Hydrometallurgy 137, 1. (2013).

ZhangH., Xu H., ZhangX., ZhangY. and Zhang, Y., Hydrometallurgy 142, 47 (2014).

B. Voigt, and A. Göbler, B. Voigt, and A. Göbler, Cryst. Res. Rechnol. 21, 1177. (1986).

M.S. Lee, J.G. Ahn, and E.C. Lee, M.S. Lee, J.G. Ahn, and E.C. Lee, Hydrometallurgy 63, 269. (2002).

X. Li, Z. Deng, C. Li, C. Wei, M. Li, G. Fan, and H. Rong, X. Li, Z. Deng, C. Li, C. Wei, M. Li, G. Fan, and H. Rong, Hydrometallurgy 156, 1. (2015).

H.N. Kang, J.Y. Lee, and J.Y. Kim, H.N. Kang, J.Y. Lee, and J.Y. Kim, Hydrometallurgy 110, 120. (2011).

D. Liu, B. Yang, Y. Dai, G. Du, W. Tang, and L. Han, D. Liu, B. Yang, Y. Dai, G. Du, W. Tang, and L. Han, Chin. J Rare Metals 29, 574. (in Chinese) (2005).

Acknowledgements

This work was supported financially by the National Natural Science Foundation of China (Grant Nos. 51964029, 51664030, 51664029, and 51804146) and Yunnan Province Applied Foundation Research Programs, China (Nos. 2020FB081 and 202001AT070079). We thank Andrew Jackson, PhD, from Liwen Bianji, Edanz Group China (www.liwenbianji.cn/ac), for editing the English text of a draft of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Deng, Z., Li, X., Wei, C. et al. Recovery of Indium from Hard Zinc Slag by Pressure Leaching and Solvent Extraction. JOM 73, 721–728 (2021). https://doi.org/10.1007/s11837-020-04519-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04519-4