Abstract

Background

Temperature gradients significantly affect the material fatigue process. A reliable and robust test procedure is needed for quantifying the effects of temperature gradients on the evolution of fatigue damage in nickel-based superalloys.

Objective

The present study aims to develop a radiation heating system for universal material testing machine for simulating thermal gradient mechanical fatigue in turbines.

Methods

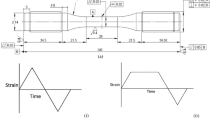

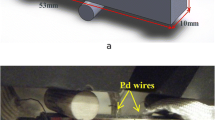

The developed heating system mainly consists of halogen lamps, reflectors, cooling subsystems, and control units. Based on extensive experimental and computational investigations, a thermal model is developed for accurate thermo-mechanical fatigue testing under given temperature gradients in the heating system, and it is applied to variable temperature fatigue tests. The detail procedure for determining heat transfer coefficients is presented based on experimental and computational results.

Results

TGMF tests are successfully performed with the developed radiation heating system. The temperature gradients are found to reduce the TGMF life significantly in comparison to that of the TMF life.

Conclusions

It is confirmed that the developed thermal gradient mechanical fatigue methodology can be applied to different thermo-mechanical fatigue tests with various temperature gradients.

Similar content being viewed by others

References

Chaboche J-L, Culié JP, Gallerneau F, Nouailhas D, Pacou D, Poirier D (1997) Thin wall thermal gradient: experimental study, FE analysis and fatigue life prediction. In: Macha E, Mroz Z (eds) The 5th Int. conf on biaxial/multiaxial fatigue & fracture, Cracow, pp 237–250

Brendel T, Affeldt E, Hammer J, Rummel C (2008) Temperature gradients in TMF specimens. Measurement and influence on TMF life. Int J Fatigue 30(2):234–240

Prasad K, Kumar V (2013) Temperature gradients in flat thermomechanical fatigue specimens. Appl Therm Eng 59(1):131–133

Baufeld B, Bartsch M, Heinzelmann M (2008) Advanced thermal gradient mechanical fatigue testing of CMSX-4 with an oxidation protection coating. Int J Fatigue 30(2):219–225

Bartsch M, Baufeld B, Dalkiliç S, Chernova L, Heinzelmann M (2008) Fatigue cracks in a thermal barrier coating system on a superalloy in multiaxial thermomechanical testing. Int J Fatigue 30(2):211–218

Wang Y, Charbal A, Dufour J, Hild F, Roux S, Vincent L (2019) Hybrid multiview correlation for measuring and monitoring thermomechanical fatigue test. Exp Mech 59:483–489

Mao J, Engler-Pinto C, Li T, Hsieh J, Su X (2015) Effect of Constitutive Model on Thermomechanical Fatigue Life Prediction. Procedia Engineering 133(313):655–668

Wang J, Moumni Z, Zhang W (2017) A thermomechanically coupled finite-strain constitutive model for cyclic pseudoelasticity of polycrystalline shape memory alloys. Int J Plast 97:194–221

Sun J, Yuan H (2019) Life assessment of multiaxial thermomechanical fatigue of a nickel-based superalloy Inconel 718. Int J Fatigue 120:228–240

Deng W, Xu J, Hu Y, Huang Z, Jiang L (2019) Isothermal and thermomechanical fatigue behavior of Inconel 718 superalloy. Materials Science and Engineering: A 742:813–819

Heckel T, Tovar AG, Christ H-J (2010) Fatigue of the near-alpha ti-alloy ti6242. Exp Mech 50:483–489

Thiele M, Gampe U, Fischer KA (2018) Novel test facility for investigation of the impact of thermally induced stress gradients on fatigue life of cooled gas turbine components. J Eng Gas Turbines Power 141(3):032502

Callaghan M, Humphries S, Law M, Bendeich P, Yeung W (2016) Special testing equipment and validation of measurement methodologies for high temperature low cycle fatigue testing of miniature metallic specimens. Exp Mech 56:1039–1050

OMEGA Engineering inc. Thermocouples - Reference Guide. https://www.omega.co.uk/temperature/z/tcref.html

ASTM-E606 (1998) Standard practice for strain-controlled fatigue testing. Am Soc Test Mater 3:525–39

ASTM-E2207-15 (2015) Standard practice for strain-controlled axial-torsional fatigue testing with thin-walled tubular specimens

Palmer J, Jones J, Dyer A, Smith R, Lancaster R, Whittaker M (2019) Development of test facilities for thermo-mechanical fatigue testing. Int J Fatigue 121:208–218

Nilsson K-F, Dolci F, Seldis T, Ripplinger S, Grah A, Simonovski I (2016) Assessment of thermal fatigue life for 316l and p91 pipe components at elevated temperatures. Eng Fract Mech 168 :73–91

Mauget F, Hamon F, Morisset M, Cormier J, Riallant F, Mendez J (2017) Damage mechanisms in an eb-pvd thermal barrier coating system during tmf and tgmf testing conditions under combustion environment. Int J Fatigue 99:225–234. recent Developments in Thermo-mechanical Fatigue

Hou N, Wen Z, Yue Z (2008) Creep behavior of single crystal superalloy specimen under temperature gradient condition. Materials Science and Engineering: a 510-511 (2009) 42–45. In: 11th International conference of creep and fracture of engineering materials and structures CREEP

Cengel YA (2010) Heat Transfer—a practical approach. McGraw-Hill, New York

Díaz-Álvarez J, Cantero J, Miguélez H, Soldani X (2014) Numerical analysis of thermomechanical phenomena influencing tool wear in finishing turning of inconel 718. Int J Mech Sci 82:161–169

Kosky P, Balmer R, Keat W, Wise G (2013) Chapter 12 - mechanical engineering. In: Kosky P, Balmer R, Keat W, Wise G (eds) Exploring engineering. 3rd edn. Academic Press, Boston, pp 259–281

(2019). Lambda-Research-Corporation, TracePro, Software for design and analysis of illumination and optical systems, Littleton USA

Incropera F, DeWitt D (2013) Fundamentals of heat and mass transfer, 6 edn. Wiley

Weigand B (2004) Analytical methods for heat transfer and fluid flow problems. Springer, Berlin

Gnielinski V (1975) Neue Gleichungen fur den Wärme- und den Stoffübergang in turbulent durchströmten Rohren und Kanälen̈. Forschung im Ingenieurwesen A 41(1):8–16

Praveen K, Singh V (2008) Effect of heat treatment on coffin–manson relationship in lcf of superalloy in718. Mater Sci Eng A 485(1):352–358

Sun J, Yuan H (2019) Cyclic plasticity modeling of nickel-based superalloy Inconel 718 under multi-axial thermo-mechanical fatigue loading conditions. Int J Fatigue 119:89–101

Sun J, Yuan H, Vormwald M (2020) Thermal gradient mechanical fatigue assessment of a nickel-based superalloy. Int J Fatigue 135:105486

Funding

The present work is financed by the China Natural Science Foundation under the contract numbers 11572169 and 51775294 as well as by the National Science and Technology Major Project of China (2017-V-0003-0040).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

Conflict of Interest: The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, J., Yuan, H. Investigation of Thermal Gradient Mechanical Fatigue Test Methods for Nickel-based Superalloys. Exp Mech 61, 565–580 (2021). https://doi.org/10.1007/s11340-020-00680-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-020-00680-8