Abstract

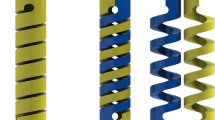

The vital sensing parameter on self-sensing actuation in the spring form of shape memory alloy (SMA) is determined through experimental analysis. A unique measurement technique is adopted that interlinks the electro–thermo–mechano features during the shape memory effect in NiTi, NiTiCu, and NiTiFe springs. The influence of the spring index, the number of active turns, material composition, and transition temperature is assessed. SMA spring’s effective functional behavior to be used as an actuator and or a sensor is ensured via the measurement of electrical parameters—the resistance, inductance, and impedance variations revealed during the solid–solid phase change, i.e., displacement. However, the spring form of SMA would exhibit variation in inductance and a variation in electrical resistance, which in turn is considered a variation in the electrical impedance, which may also be appropriate sensing information. The thermo-mechanical and thermo-electrical measurements are synchronized using an impedance analyzer and data acquisition module with a specific programming technique. The active spring is equivalently a series resistance–inductance circuit, since the collective effect of a decrease in resistance and increase in inductance with an increase in temperature offers increased \(\frac{L}{R}\) and vice versa to support structural health monitoring.

Similar content being viewed by others

References

Otsuka, K.; Wayman, C.M.: Shape Memory Materials. Cambridge University, Cambridge (1999)

Bhattacharya, K.: Microstructure of Martensite: Why It Forms and How It Gives Rise to the Shape-Memory Effect?. Oxford University Press, New York (2003)

Hartl, D.J.; Lagoudas, D.C.; Calkins, F.T.; Mabe, J.H.: Use of a Ni60Ti shape memory alloy for active jet engine chevron application: I—thermomechanical characterization. Smart Mater. Struct. 19, 015021 (2010). https://doi.org/10.1088/0964-1726/19/1/015020

Costanza, G.; Tata, M.E.; Calisti, C.: Nitinol one-way shape memory springs: thermomechanical characterization and actuator design. Sens. Actuators, A (2010). https://doi.org/10.1016/j.sna.2009.11.008

Kim, S.W.; Koh, J.S.M.; Cho, K.J.: Towards a biomimetic flytrap robot based on a snap-through mechanism. In 3rd IEEE RAS and EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Tokyo, Japan, 26–29 September (2010)

TOKI Corporation: Bio-metal. Artificial Metal based muscle for long stroke actuators, Bio-Metal Helix, BMX series. http://www.toki.co.jp/biometal/download/downloadfilesBMX_Catalog_140217.pdf. Accessed 28 Oct 2017) (n.d.)

Spinella, I.; Dragoni, E.: Analysis and design of hollow helical springs for shape memory actuators. J. Intell. Mater. Syst. Struct. (2010). https://doi.org/10.1177/1045389X09356021

Kim, H.; Han, Y.; Lee, D.; Ha, J.-I.; Cho, K.-J.: Sensorless displacement estimation of a shape memory alloy coil spring actuator using inductance. Smart Mater. Struct. (2013). https://doi.org/10.1088/0964-1726/22/2/025001

Sreekanth, M.; Abraham, T.M.; Vijayakumar, R.: A novel model-based approach for resistance estimation using rise time and sensorless position control of sub-millimetre shape memory alloy helical spring actuator. J. Intell. Mater. Syst. Struct. (2018). https://doi.org/10.1177/1045389X17730911

Zhang, J.J.; Yin, Y.H.; Zhu, J.Y.: Electrical resistivity-based study of self-sensing properties for shape memory alloy-actuated artificial muscle. Sensors (2013). https://doi.org/10.3390/s131012958

Ikuta, K.; Tsukamoto, M.; Hirose, S.: Shape memory alloy servo actuator system with electric resistance feedback and application for active endoscope. In: IEEE International Conference on Robotics and Automation (ICRA), Philadelphia, PA, 24–29 April (1988)

Cui, D.; Song, G.; Li, H.: Modeling of the electrical resistance of shape memory alloy wires. Smart Mater. Struct. (2010). https://doi.org/10.1088/0964-1726/19/5/055019

Novák, V.; Šittner, P.; Dayananda, G.N.; Braz-Fernandes, F.M.; Mahesh, K.K.: Electric resistance variation of NiTi shape memory alloy wires in thermomechanical tests: experiments and simulation. Mater. Sci. Eng., A (2008). https://doi.org/10.1016/j.msea.2007.02.162

Shayanfard, P.; Kadkhodaei, M.; Jalalpour, A.: Numerical and experimental investigation on electro-thermo mechanical behavior of NiTi shape memory alloy wires. Iran J. Sci. Technol. Trans. Mech. Eng. (2018). https://doi.org/10.1007/s40997-018-0183-8

Kellogg’s Research Lab: Nitinol springs. https://www.kelloggsresearchlabs.com/Nitinol/Nitinol-springs. Accessed 3 April 2019

Tobushi, H.; Tanaka, K.: Deformation of a shape memory alloy helical spring: analysis based on stress-strain-temperature relation. JSME Int. J. Ser. Solid Mech. Strength Mater. (1991). https://doi.org/10.1299/jsmea1988.34.1_83

Lagoudas, D.C.: Memory Alloys, Modeling and Engineering Applications. Springer, Berlin (2008)

An, S.M.; Ryu, J.; Cho, M.; Cho, K.J.: Engineering design framework for a shape memory alloy coil spring actuator using a static two-state model. Smart Mater. Struct. (2012). https://doi.org/10.1088/0964-1726/21/5/055009

Seok, S.; Onal, C.D.; Cho, K.J.; Wood, R.J.; Rus, D.; Kim, S.: Meshworm: a peristaltic soft robot with antagonistic nickel titanium coil actuators. IEEE/ASME Trans. Mechatron. (2012). https://doi.org/10.1109/tmech.2012.2204070

Simões, J.B.; Santiago, J.J.M.; Silva, P.C.S.; deAraujo, C.J.: Mechanical behavior of Ni-Ti SMA helical springs manufactured by investment casting. Res. Dev. Mater. Sci. (2018). https://doi.org/10.31031/rdms.2018.05.000606

Aguiar, R.A.A.; Savi, M.A.; Pacheco, P.M.C.L.: Experimental and numerical investigations of shape memory alloy helical springs. Smart Mater. Struct. (2010). https://doi.org/10.1088/0964-1726/19/2/025008

Cortez-Vega, R.; Chairez, I.; Luviano-Juarez, A.; Feliu-Batlle, V.: A hybrid dynamic model of SMA spring. Actuators Meas. (2017). https://doi.org/10.1016/j.measurement.2017.08.041.10

Enemark, S.; Savi, M.A.; Santos, I.F.: Experimental analysis of dynamical systems and involving shape memory alloys. Smart Struct. Syst. (2015). https://doi.org/10.12989/sss.2015.15.6.1521

Bhargaw, H.N.; Ahmed, M.; Sinha, P.: Thermo-electric behaviour of NiTi shape memory alloy. Trans. Nonferrous Met. Soc. China (2013). https://doi.org/10.1016/S1003-6326(13)62737-5

Faulkner, M.G.; Amalraj, J.J.; Bhattacharyya, A.: Experimental determination of thermal and electrical properties of Ni-Ti shape memory wires. Smart Mater. Struct. (2000). https://doi.org/10.1088/0964-1726/9/5/307

Yates, S.; Kalamkarov, A.: Experimental study of helical shape memory alloy actuators: effects of design and operating parameters on thermal transients and stroke. Metals (2013). https://doi.org/10.3390/met3010123

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Devashena, T., Dhanalakshmi, K. Simultaneous Measurements in Shape Memory Alloy Springs to Enable Structural Health Monitoring by Self-Sensing Actuation. Arab J Sci Eng 46, 6015–6025 (2021). https://doi.org/10.1007/s13369-020-05259-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-05259-y