Abstract

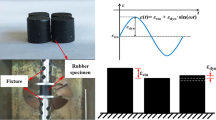

In the present work, analysis of the thermal behavior of a rubber cylinder under the repeated deformation is studied. This problem is divided into two correlated parts including transient thermal heat conduction and cyclic mechanical loading. To find the best approach-numerical method, the problem is modeled and analyzed by three approaches including coupled approach-FEM, uncoupled approach-FEM as well as Green’s function. To evaluate the dissipating energy due to hysteresis, the Prony–Mooney–Rivlin constitutive hyper-viscoelastic mathematical model is considered. To model the thermal effects and heat buildup due to dissipating energy, this energy is accounted for as a heat source inside the part in three different forms including pointwise, planar, and volumetric. It is shown that the FEM-based coupled approach presents the most accurate estimation. However, for steady-state estimation of mid-point and wall-point temperatures, the best method is Green’s function with the planar and the volumetric heat source assumptions. Moreover, a study on the effect of frequency of loading cycles in temperature distribution shows that the more the frequency, the larger the difference between the temperature of the mid-point and wall-point, and the higher maximum temperature inside the rubber.

Similar content being viewed by others

Abbreviations

- w :

-

Stored strain energy function

- Q :

-

Dissipated energy

- σ v :

-

The rate-dependent stress

- σ h :

-

Hyperelastic stress

- δ :

-

Loss angle

- E* :

-

Complex modulus

- E′:

-

Storage modulus

- E″:

-

Loss modulus

- I i :

-

Invariants of Cauchy–Green strain tensor

- J :

-

Jacobian

- E ∞ :

-

Long-term modulus

- E i :

-

Relaxation modulus

- θ i :

-

Relaxation time

- C pq :

-

Model parameters

References

Lin YY, Cheng CM, Sun D (2000) Wind—induced vibration control of long—span bridges by multiple tuned mass dampers. Tamkang J Sci Eng 3(1):1–13

Johnson AR, Chen TK (2005) Approximating thermo-viscoelastic heating of largely strained solid rubber components. Comput Methods Appl Mech Eng 194(2–5):313–325

Simo JC, Taylor RL (1991) Quasi-incompressible finite elasticity in principal stretches continuum basis and numerical algorithms. Comput Methods Appl Mech Eng 85:273–310

Reese S, Govindjee S (1998) Theoretical and numerical aspects in the thermos-viscoelastic material behavior of rubber-like polymers. Mech Time Depend Mater 1:357–396

Melnik R, Strunin DV, Roberts AJ (2005) Nonlinear analysis of rubber based polymeric materials with thermal relaxation models. Numer Hear Transf Part A 47:549–569

Behnke R, Kaliske M, Kluppel M (2006) Thermomechanical analysis of cyclically loaded particle-reinforced elastomer components: experiment and finite element simulation. Rubber Chem Technol 89(1):154–176

Li F, Liu J, Yang H, Lu Y, Zhang L (2016) Numerical simulation and experimental verification of heat buildup for rubber compounds. Polymer 101:199–206

Armero F, Simo J (1992) A new unconditionally stable fractional step method for non-linear coupled thermomechanical problems. Int J Numer Method Eng 35:737–766

Mazaras J, Pijaudier-Cabot G (1989) Continuum damage theory—application to concrete. J Eng Mech 115:345–365

Stabler J, Baker G (2000) Fractional step methods for thermomechanical damage analyses at transient elevated temperatures. Int J Numer Methods Eng 48(5):761–785

Erbts P, Duster A (2012) Accelerated staggered coupling schemes for problems of thermoelasticity at finite strains. Comput Math Appl 64(8):2408–2430. https://doi.org/10.1016/j.camwa.2012.05.010

Martins JMP, Neto DM, Alves JL, Oliveira MC, Laurent H, Andrade-Campos A, Menezes LF (2017) A new staggered algorithm for thermomechanical coupled problems. Int J Solids Struct 122:42–58. https://doi.org/10.1016/j.ijsolstr.2017.06.002

Le Chenadec Y, Raoult I, Stolz C, Nguyen-Tajan M (2009) Cyclic Approximation of the heat equation in finite strains for the heat buildup problem of rubber. J Mech Mater Struct 4(2):309–318

Banic M, Miltrnovic V, Milosevic M, Miltenovic A, Jovanovic N (2012) Heat generation prediction in the railway draw gear rubber-metal spring. Facta Univ Ser Mech Eng 10(2):171–180

Tong X, Chen X, Xu J-S, Zheng Y, Zhi S-J (2018) The heat buildup of a polymer matrix composite under cyclic loading: experimental assessment and numerical simulation. Int J Fatigue 116:323–333

Luo W, Yin B, Hu X, Zhou Zh, Deng Y, Song K (2018) Modeling of the heat buildup of carbon black filled rubber. Polym Test 69:116–124

Ovalle C, Boisot G, Laiarinandrasana L (2020) Effects of stress triaxiality ratio on the heat buildup of PolyAmide 11 under loading. Mech Mater 145:103375. https://doi.org/10.1016/j.mechmat.2020.103375

Rittel D (2000) An investigation of the heat generated during cyclic loading of two glassy polymers. Part I: Experimental. Mech Mater 32(3):131–147

Arruda EM, Boyce MC (1993) A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J Mech Phys Solids 41(2):389–412. https://doi.org/10.1016/0022-5096(93)90013-6

Lin YJ, Hwang SJ (2004) Temperature prediction of rolling tires by computer simulation. Math Comput Simul 67(3):235–249

Beda T (2007) Modeling hyperelastic behavior of rubber: a novel invariant-based and a review of constitutive models. J Polym Sci Part B Polym Phys 45(13):1713–1732

Masquelier I, Marco Y, Le Saux V, Calloch S, Charrier P (2015) Determination of dissipated energy fields from temperature mappings on a rubber-like structural sample: experiments and comparison to numerical simulations. Mech Mater 80:113–123

Khajehsaeid H, Arghavani J, Naghdabadi R (2013) A hyperelastic constitutive model for rubber-like materials. Eur J Mech A Solids 38:144–151

Pichon PG, Boutaous MH, Méchin F, Sautereau H (2012) Measurement and numerical simulation of the self-heating of cross-linked segmented polyurethanes under cyclic loading. Eur Polym J 48(4):684–695

Luo RK, Wu WX, Mortel WJ (2005) A method to predict the heat generation in a rubber spring used in the railway industry. Proc Inst Mech Eng Part F J Rail Rapid Transit 219(4):239–244. https://doi.org/10.1243/095440905X8862

Molinari A, Germain Y (1996) Self-heating and thermal failure of polymers sustaining a compressive cyclic loading. Int J Solids Struct 33(23):3439–3462. https://doi.org/10.1016/0020-7683(95)00184-0

Greenberg MD (1971) Application of Green’s function in science and engineering. Prentice-Hall, Englewood Cliffs

Stakgold I (1979) Green’s function and boundary value problems. Wiley, New York

Morse PM, Feshbach H (1953) Methods of theoretical physics. McGraw-Hill, New York

Ozisik MN (1968) Boundary value problems of heat conduction. International Textbook, Scranton

Hahn DW, Özisik MN (2012) Heat conduction. Wiley, Hoboken

Banić MS, Stamenković DS, Miltenović V, Milošević MS, Miltenović AV, Đekić PS, Rackov MJ (2012) Prediction of heat generation in rubber or rubber-metal springs. Therm Sci 16(suppl. 2):527–539

Khedmati Bazkiaei A, Heidari Shirazi K, Shishesaz M (2020) A framework for model base hyper-elastic materials simulation. J Rubber Res. https://doi.org/10.1007/s42464-020-00057-5 (Under publication)

Stamenković D (2010) Development and validation of electro locomotives primary suspension rubber-metal elements. In: Proceedings, XIV scientific-expert conference on railways, Serbia, pp 79–83

Moran MJ, Shapiro HN (2006) Fundamentals of engineering thermodynamics. Wiley, Chichester

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bazkiaei, A.K., Shirazi, K.H. & Shishesaz, M. Thermo-hyper-viscoelastic analysis of a rubber cylinder under cyclic deformation. J Rubber Res 24, 13–26 (2021). https://doi.org/10.1007/s42464-020-00068-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-020-00068-2