Abstract

In recent years, block caving has drawn the attention of many mine enterprises due to the admired extraction rate and lower cost, which can exploit the materials via gravity inflow. At the same time, the limitation of this advanced method cannot be underestimated easily, such as surface subsidence and boulder, usually, the latter leads to the frequent secondary blast and damage of bottom structure. Thus, it is significant and crucial to evaluate the fragmentation before the implement of this method. But, traditional fragmentation assessment model suffers from the complex process of modeling and simulation. In this study, a hybrid model consists of unascertained measurement theory and information entropy was constructed to meet the requirements of this prospective mining method. Considering the influence of various parameters on rock fragmentation at the same time, twenty-three factors (i.e., uniaxial compressive strength, modulus ratio, fracture frequency, aperture, persistence, joint orientation, roughness, infilling, weathering, in situ stresses, stress orientation, stress ratio, underground water, fine ratio, hydraulic radius, undercut height, draw column height, draw points geometry, draw rate, multiple draw interaction, air gap height, broken ore density and undercut direction) were chosen to extract the main characteristics of rock mass samples from the two different mines, namely Reserve North (Chile), Diablo Regimiento (Chile) and Kemess mine (Canada). A new membership function (logarithm curve) was added to eliminate uncertainty results from the low level of knowledge about rock mass properties. Then, information entropy was performed to quantify the impacts of individual index. A credible degree identification criterion (Rη) was also applied to review the sample attributes qualitatively. Ultimately, degree of fragmentation of the three samples was judged easily on the basis of a composite measurement vectors and Rη. The evaluation results showed that the fragmentation grades of Reserve North, Diablo Regimiento and Kemess mine, separately, were “Good”, “Medium” and “Good”. With regard to the excellent performance of this hybrid model, it can be seen as a reliable approach to describe the fragmentation potential during the ore extraction using block caving mining method.

Similar content being viewed by others

References

Melo F, Vivanco F, Fuentes C (2009) Calculated isolated extracted and movement zones compared to scaled models for block caving. Int J Rock Mech Min Sci 46:731–737. https://doi.org/10.1016/j.ijrmms.2008.09.012

Chen X, Liu Y, Ge Q et al (2019) Study on caving fragmentation prediction of block caving with BCF software. China Mine Eng 48(6):6–9

Sánchez V, Castro RL, Palma S (2019) Gravity flow characterization of fine granular material for Block Caving. Int J Rock Mech Min Sci 114:24–32. https://doi.org/10.1016/j.ijrmms.2018.12.011

Zhang D (2003) Rock mechanics of block caving method and ore-caved fragmentation. In: Proceedings of the fifth annual conference of China nonferrous metals society, Beijing, China, pp 95–96+122

Guo L, Hou K, Feng X et al (2020) Risk assessment of natural caving mining process in Pulang copper mine based on FSE–ANP. Ind Saf Environ Prot 46(1):9–12

Noriega R, Pourrahimian Y, Ben-Awuah E (2020) A two-step mathematical programming framework for undercut horizon optimization in block caving mines. Resour Policy 65:101586. https://doi.org/10.1016/j.resourpol.2020.101586

Someehneshin J, Oraee-Mirzamani B, Oraee K (2015) Analytical model determining the optimal block size in the block caving mining method. Indian Geotech J 45(2):156–168. https://doi.org/10.1007/s40098-014-0119-1

Vyazmensky A, Elmo D, Stead D (2010) Role of rock mass fabric and faulting in the development of block caving induced surface subsidence. Rock Mech Rock Eng 43(5):533–556. https://doi.org/10.1007/s00603-009-0069-6

Castro R, Trueman R, Halim A (2007) A study of isolated draw zones in block caving mines by means of a large 3D physical model. Int J Rock Mech Min Sci 44(6):860–870. https://doi.org/10.1016/j.ijrmms.2007.01.001

Orellana LF, Castro R, Hekmat A et al (2017) Productivity of a continuous mining system for block caving mines. Rock Mech Rock Eng 50(3):657–663. https://doi.org/10.1007/s00603-016-1107-9

Castro R, Gómez R, Pierce M et al (2020) Experimental quantification of vertical stresses during gravity flow in block caving. Int J Rock Mech Min Sci 127:104237. https://doi.org/10.1016/j.ijrmms.2020.104237

Guo L, Sun W, Feng X et al (2019) Identification of dangerous sources of natural caving mining technology in Pulang copper mine. Resour Inf Eng 34(1):50–51. https://doi.org/10.19534/j.cnki.zyxxygc.2019.01.024

Woo K-S, Eberhardt E, Elmo D et al (2013) Empirical investigation and characterization of surface subsidence related to block cave mining. Int J Rock Mech Min Sci 61:31–42. https://doi.org/10.1016/j.ijrmms.2013.01.015

Rafiee R, Ataei M, Khalookakaie R (2015) A new cavability index in block caving mines using fuzzy rock engineering system. Int J Rock Mech Min Sci 77:68–76

Rafiee R, Ataei M, KhalooKakaie R et al (2018) Numerical modeling of influence parameters in cavabililty of rock mass in block caving mines. Int J Rock Mech Min Sci 105:22–27. https://doi.org/10.1016/j.ijrmms.2018.03.001

Wang M, Shi X, Zhou J et al (2018) Multi-planar detection optimization algorithm for the interval charging structure of large-diameter longhole blasting design based on rock fragmentation aspects. Eng Optim 50(12):2177–2191

Zhou J, Li C, Arslan CA et al (2019) Performance evaluation of hybrid FFA-ANFIS and GA-ANFIS models to predict particle size distribution of a muck-pile after blasting. Eng Comput. https://doi.org/10.1007/s00366-019-00822-0

Shi X, Huang D, Zhou J et al (2013) Combined ANN prediction model for rock fragmentation distribution due to blasting. J Inf Comput Sci 10(11):3511–3518

Shi X, Zhou J, Wu B et al (2012) Support vector machines approach to mean particle size of rock fragmentation due to bench blasting prediction. Trans Nonferrous Met Soc China 22(2):432–441

Wang M, Shi X, Zhou J (2018) Charge design scheme optimization for ring blasting based on the developed scaled Heelan model. Int J Rock Mech Min Sci 110:199–209

Wang M, Shi X, Zhou J (2019) Optimal charge scheme calculation for multiring blasting using modified harries mathematical model. J Perform Constr Facil 33(2):04019002

Li XB, Zhou J, Wang SF, Liu B (2017) Review and practice of deep mining for solid mineral resources. Chin J Nonferrous Met 27(7):1236–1262

Laubscher D (1994) Cave mining—the state of the art. J S Afr Inst Min Metall 94(10):279–293

Brown E (2002) Block caving geomechanics. Julius Kruttschnitt Mineral Research Centre, The University of Queensland

Jiang F, Li X, Zhang H et al (2014) Research on block caving fragmentation prediction and its distribution of thick orebody with steep dip angle. Ming Res Dev 34(2):6–10. https://doi.org/10.13827/j.cnki.kyyk.2014.02.003

Balakrishnan V, Pradhan M, Dhekne PY (2020) Investigating rock fragmentation in distributed spherical air-gap blasting technique. Powder Technol 362:101–110. https://doi.org/10.1016/j.powtec.2019.11.110

Wang LG, Yamashita S, Sugimoto F et al (2003) A methodology for predicting the in situ size and shape distribution of rock blocks. Rock Mech Rock Eng 36(2):121–142. https://doi.org/10.1007/s00603-002-0039-8

Chen J, Li X, Li W (2017) Research on block prediction and control technology of natural caving method in Yechangping molybdenum mine. Min Technol 17(3):19–21. https://doi.org/10.13828/j.cnki.ckjs.2017.03.007

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech 6(4):189–236. https://doi.org/10.1007/BF01239496

Babaeian M, Ataei M, Sereshki F et al (2019) A new framework for evaluation of rock fragmentation in open pit mines. J Rock Mech Geotech Eng 11(2):325–336. https://doi.org/10.1016/j.jrmge.2018.11.006

Singh BK, Mondal D, Shahid M et al (2019) Application of digital image analysis for monitoring the behavior of factors that control the rock fragmentation in opencast bench blasting: a case study conducted over four opencast coal mines of the Talcher Coalfields, India. J Sustain Min 18(4):247–256. https://doi.org/10.1016/j.jsm.2019.08.003

Feng X, Li D, Wang L et al (2011) Analysis of influential factors for ore-rock fragmentation prediction. Min Metall Eng 31(3):8–12

Chen Z, Wang L, Feng X et al (2013) Application of 3D simulation of fragment size in block caving in a copper mine. Min Metall Eng 33(2):1–4

Hekmat A, Munoz S, Gomez R (2019) Prediction of rock fragmentation based on a modified Kuz-Ram model. In: Widzyk-Capehart E, Hekmat A, Singhal R (eds) Proceedings of the 27th international symposium on mine planning and equipment selection—MPES 2018, Cham, 2019. Springer International Publishing, pp 69–79

Paluszny A, Zimmerman RW (2017) Modelling of primary fragmentation in block caving mines using a finite-element based fracture mechanics approach. Geomech Geophys Geoenergy Georesour 3(2):121–130. https://doi.org/10.1007/s40948-016-0048-9

Gómez R, Castro RL, Casali A et al (2017) A comminution model for secondary fragmentation assessment for block caving. Rock Mech Rock Eng 50(11):3073–3084. https://doi.org/10.1007/s00603-017-1267-2

Zhou J, Li E, Yang S et al (2019) Slope stability prediction for circular mode failure using gradient boosting machine approach based on an updated database of case histories. Saf Sci 118:505–518

Li C, Zhou J, Jahed Armaghani D et al (2020) Stability analysis of underground mine hard rock pillars via combination of finite difference methods, neural networks, and Monte Carlo simulation techniques. Undergr Space. https://doi.org/10.1016/j.undsp.2020.05.005

Monjezi M, Mohamadi HA, Barati B et al (2014) Application of soft computing in predicting rock fragmentation to reduce environmental blasting side effects. Arab J Geosci 7(2):505–511

Zhou J, Koopialipoor M, Li E et al (2020) Prediction of rockburst risk in underground projects developing a neuro-bee intelligent system. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-020-01788-w

Fang Q, Nguyen H, Bui XN et al (2020) Modeling of rock fragmentation by firefly optimization algorithm and boosted generalized additive model. Neural Comput Appl. https://doi.org/10.1007/s00521-020-05197-8

Zhou J, Li C, Alparslan C et al (2019) Performance evaluation of hybrid FFA-ANFIS and GA-ANFIS models to predict particle size distribution of a muck-pile after blasting. Eng Comput. https://doi.org/10.1007/s00366-019-00822-0

Hasanipanah M, Armaghani DJ, Monjezi M et al (2016) Risk assessment and prediction of rock fragmentation produced by blasting operation: a rock engineering system. Environ Earth Sci 75(9):808

Bui XN, Nguyen H, Choi Y et al (2020) Prediction of slope failure in open-pit mines using a novel hybrid artificial intelligence model based on decision tree and evolution algorithm. Sci Rep 10(1):1–17

Zhou J, Li X, Mitri HS (2018) Evaluation method of rockburst: state-of-the-art literature review. Tunn Undergr Space Technol 81:632–659

Zhou J, Li C, Koopialipoor M et al (2021) Development of a new methodology for estimating the amount of PPV in surface mines based on prediction and probabilistic models (GEP-MC). Int J Min Reclamat Environ 35(1):48–68. https://doi.org/10.1080/17480930.2020.1734151

Li E, Zhou J, Shi X et al (2020) Developing a hybrid model of salp swarm algorithm-based support vector machine to predict the strength of fiber-reinforced cemented paste backfill. Eng Comput. https://doi.org/10.1007/s00366-020-01014-x

Yu Z, Shi X, Zhou J et al (2019) Feasibility of the indirect determination of blast-induced rock movement based on three new hybrid intelligent models. Eng Comput. https://doi.org/10.1007/s00366-019-00868-0

Armaghani DJ, Mirzaei F, Shariati A et al (2020) Indirect measure of shear strength parameters of fiber-reinforced sandy soil using laboratory tests and intelligent systems. Geomech Eng. https://doi.org/10.12989/gae.2020.22.5.397

Asteris P, Douvika M, Karamani C et al (2020) A novel heuristic global algorithm to predict the COVID-19 pandemic trend. Comput Sci Eng. https://doi.org/10.1101/2020.04.16.20068445

Li D, Armaghani DJ, Zhou J, Lai SH, Hasanipanah M (2020) A GMDH predictive model to predict rock material strength using three non-destructive tests. J Nondestr Eval 39(4):1–14

Cai M, Koopialipoor M, Armaghani DJ et al (2020) Evaluating slope deformation of earth dams due to earthquake shaking using MARS and GMDH techniques. Appl Sci 10(4):1486. https://doi.org/10.3390/app10041486

Bayat P, Monjezi M, Rezakhah M et al (2020) Artificial neural network and firefly algorithm for estimation and minimization of ground vibration induced by blasting in a mine. Nat Resour Res 29:4121–4132. https://doi.org/10.1007/s11053-020-09697-1

Lu S, Koopialipoor M, Asteris PG et al (2020) A novel feature selection approach based on tree models for evaluating the punching shear capacity of steel fiber-reinforced concrete flat slabs. Materials. https://doi.org/10.3390/ma13173902

Zhou J, Qiu Y, Armaghani DJ, Zhang W, Li C, Zhu S, Tarinejad R (2020) Predicting TBM penetration rate in hard rock condition: A comparative study among six XGB-based metaheuristic techniques. Geoscience Frontiers. https://doi.org/10.1016/j.gsf.2020.09.020

Yu Z, Shi X, Zhou J et al (2020) A new multikernel relevance vector machine based on the HPSOGWO algorithm for predicting and controlling blast-induced ground vibration. Eng Comput. https://doi.org/10.1007/s00366-020-01136-2

Zhou J, Qiu Y, Zhu S, Armaghani DJ, Li C, Nguyen H, Yagiz S (2021) Optimization of support vector machine through the use of metaheuristic algorithms in forecasting TBM advance rate. Eng Appl Artif Intell 97:104015

Zhou J, Qiu Y, Zhu S, Armaghani DJ, Khandelwal M, Mohamad ET (2020) Estimation of the TBM advance rate under hard rock conditions using XGBoost and Bayesian optimization. Undergr Space. https://doi.org/10.1016/j.undsp.2020.05.008

Zhang WG, Li HR, Wu CZ, Li YQ, Liu ZQ, Liu HL (2020) Soft computing approach for prediction of surface settlement induced by earth pressure balance shield tunneling. Undergr Space. https://doi.org/10.1016/j.undsp.2019.12.003

Gong F, Li X, Dong L et al (2008) Underground goaf risk evaluation based on unascertained measurement theory. Chin J Rock Mech Eng 27(2):323–330

Shi X, Zhou J (2009) Application of uncertainty average clustering measurement model to classification of tunnel surrounding rock. J Civ Archit Environ Eng 31(2):62–67

Liu A, Dong L, Dong L (2010) Optimization model of unascertained measurement for underground mining method selection and its application. J Cent S Univ Technol 17(4):744–749

Zhao K, Wang Q, Yan Y, et al (2019) Geological structural surface evaluation model based on unascertained measure. Geofluids. https://doi.org/10.1155/2019/3547384

Tang H, Wan W, Liu J (2011) Evaluation of underground cavern rock quality based on uncertainty measure theory. Rock Soil Mech 32(4):1181–1185. https://doi.org/10.16285/j.rsm.2011.04.015

Zhao G, Yu P, Zhou L (2013) Classification of rock mass blastability based on unascertained measurement theory. Blasting 30(4):20–24. https://doi.org/10.3963/j.issn.1001-487X.2013.04.005

Shi X, Zhou J, Dong L et al (2010) Application of unascertained measurement model to prediction of classification of rockburst intensity. Chin J Rock Mech Eng 29(S1):2721–2727

Zhou J, Li X (2012) Integrating unascertained measurement and information entropy theory to assess blastability of rock mass. J Cent S Univ 19(7):1953–1960

Song Y (2012) Risk evaluation on geological hazards under construction of Huangdao underground water-sealed oil storage caverns. Master, China University of Geosciences for master degree (Beijing)

Li Y, Yang J, Shi H et al (2017) Assessment of sustainable urban transport development based on entropy and unascertained measure. PLoS ONE. https://doi.org/10.1371/journal.pone.0186893

Fang J, He H, An L et al (2019) The evaluation of potential for the exploration and development of coalbed methane resources based on an improved uncertainty measure optimization model. Energy Explor Exploit 37(1):315–331

Huang C, Li Q, Wu S et al (2019) Subgrade stability evaluation in permafrost regions based on unascertained measurement model. Geotech Geol Eng 37(2):707–719

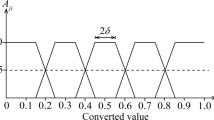

Zhou J, Chen C, Armaghani D et al (2020) Developing a hybrid model of information entropy and unascertained measurement theory for evaluation of the excavatability in rock mass. Eng Comput. https://doi.org/10.1007/s00366-020-01053-4

Zhou J, Chen C, Du K et al (2020) A new hybrid model of information entropy and unascertained measurement with different membership functions for evaluating destressability in burst-prone underground mines. Eng Comput. https://doi.org/10.1007/s00366-020-01151-3

Wang G (1990) Unascertained information and its mathmatical treatment. J Harbin Inst Civ Eng 23(4):1–8

Cheng Q (1997) Attribute sets and attribute synthetic assessment system. Syst Eng Theory Pract 17(9):1–8

Cheng Q (1997) Attribute recognition theoretical model with application. J Peking Univ (Nat Sci Ed) 33(1):13–19. https://doi.org/10.13209/j.0479-8023.1997.002

Li L, Tang CA, Zhao X et al (2014) Block caving-induced strata movement and associated surface subsidence: a numerical study based on a demonstration model. Bull Eng Geol Environ 73(4):1165–1182

Ltd RE (2003) Underground mining method. Ulf Linder, Sweden, pp 1–120

Azadmehr A, Jalali SME, Pourrahimian Y (2019) An application of rock engineering system for assessment of the rock mass fragmentation: a hybrid approach and case study. Rock Mech Rock Eng 52(11):4403–4419

Rafiee R, Ataei M, Khalokakaie R et al (2015) Determination and assessment of parameters influencing rock mass cavability in block caving mines using the probabilistic rock engineering system. Rock Mech Rock Eng 48(3):1207–1220

Stille H, Palmstrom A (2003) Classification as a tool in rock engineering. Tunn Undergr Space Technol 18(4):331–345

Wang S, Liu Y, Du K, Zhou J, Khandelwal M (2020) Waveform features and failure patterns of hollow cylindrical sandstone specimens under repetitive impact and triaxial confinements. Geomech Geophys Geo-Energy Geo-Res 6(4):1–8. https://doi.org/10.1007/s40948-020-00183-9

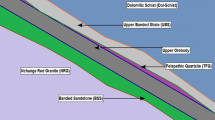

Brzovic A, Villaescusaa E (2007) Rock mass characterization and assessment of block-forming geological discontinuities during caving of promary copper ore at the El Teniente mine, Chile. Int J Rock Mech Min Sci 44:565–583. https://doi.org/10.1016/j.ijrmms.2006.09.010

Andrew W, Chris B, Gordon S (2012) Technical report for the kemess. Independent technical report for the Kemess Underground Project. SRK Consulting (Canada) Inc, Canada

Acknowledgements

This research was funded by the National Science Foundation of China (41807259), the National Key R&D Program of China (2017YFC0602902) and the Innovation-Driven Project of Central South University (No. 2020CX040).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhou, J., Chen, C., Khandelwal, M. et al. Novel approach to evaluate rock mass fragmentation in block caving using unascertained measurement model and information entropy with flexible credible identification criterion. Engineering with Computers 38 (Suppl 5), 3789–3809 (2022). https://doi.org/10.1007/s00366-020-01230-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-020-01230-5