Abstract

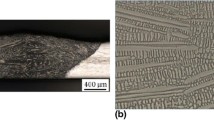

The microstructure evolution and the pitting corrosion resistance of a supermartensitic stainless steel after deep cryogenic treatment process were clarified through X-ray diffraction, field emission scanning electron microscopy, transmission electron microscopy (TEM) and electrochemical methods. The results showed that the microstructure of supermartensitic stainless steel mainly consisted of reversed austenite, tempered martensite, and M23C6 carbides after tempering. The deep cryogenic treatment promoted the refinement of the martensite laths and the precipitation of the carbides in comparison with the traditional process. TEM analysis indicated that the segregation of Si atoms at the boundary was found at the interface between carbide and martensite. The pitting corrosion potential of the specimens subjected to deep cryogenic treatment decreased with the elevated tempering temperature, and the lowest pitting corrosion potential was found at the tempering temperature of 650 °C. The sensitivity of the pitting corrosion potential was attributed to the precipitation of M23C6 carbides and Si atoms segregation. Si atoms segregation engendered the formation of Cr-depleted zone near M23C6 and impeded the recovery of Cr-depleted zone.

Similar content being viewed by others

References

W. Li, H. Gong, Z. Bai, D. Chen, Mater. Rep. 14 (2000) No. 3, 16–18.

W. Reitz, J. Pendray, Mater. Manuf. Process 16 (2001) 829–840.

S. Akincioğlu, H. Gökkaya, İ. Uygur, Int. J. Adv. Manuf. Technol. 78 (2015) 1609–1627.

P. Baldissera, C. Delprete, Open Mech. Eng. J. 2 (2008) 1–11.

A. Akhbarizadeh, K. Amini, S. Javadpour, Mater. Des. 41 (2012) 114–123.

S. Ramesh, B. Bhuvaneswari, G.S. Palani, D. Mohan Lal, R. Nagesh Iyer, J. Mech. Sci. Technol. 31 (2017) 123–132.

S. Ramesh, B. Bhuvaneshwari, G.S. Palani, D. Mohan Lal, K. Mondal, R.K. Gupta, Vacuum 159 (2018) 468–475.

G. Prieto, J.E. Perez Ipina, W.R. Tuckart, Mater. Sci. Eng. A 605 (2014) 236–243.

Y. Zhang, D. Zhan, X. Qi, Z. Jiang, Mater. Charact. 144 (2018) 393–399.

S.K. Bonagani, V. Bathula, V. Kain, Corros. Sci. 131 (2018) 340–354.

J.O. Park, S. Matsch, H. Böhni, J. Electrochem. Soc. 149 (2002) B34–B39.

P.I. Nice, J.W. Martin, NACE Int. 2005 (2005) 3–7.

I. Muto, Y. Izumiyama, N. Hara, J. Electrochem. Soc. 154 (2007) C439–C444.

R. Ke, R. Alkire, J. Electrochem. Soc. 142 (1995) 4056–4062.

S.E. Lott, R.C. Alkire, J. Electrochem. Soc. 136 (1989) 973–979.

D. Macdonald, Pure Appl. Chem. 71 (1999) 951–978.

D.D. Macdonald, G.R. Engelhardt, Shreir’s Corros. 2 (2010) 1630–1679.

W. Wang, V. Srinivasan, S. Siva, B. Albert, M. Lal, A. Alfantazi, Corrosion 70 (2014) 708–720.

P. Baldissera, C. Delprete, Mater. Des. 31 (2010) 4731–4737.

J. Tian, W. Wang, M. Babar Shahzad, W. Yan, Y. Shan, Z. Jiang, K. Yang, Acta Metall. Sin. (Engl. Lett.) 31 (2018) 785–797.

J. Lv, H. Luo, T. Liang, Mater. Chem. Phys. 163 (2015) 496–500.

Y. Lv, H. Luo, J. Tang, J. Guo, J. Pi, K. Ye, Mater. Res. Bulletin 107 (2018) 421–429.

S. Zheng, X. Bai, S. Li, J. Liang, K. Zhao, J. Iron Steel Res. 27 (2015) No. 9, 63–67.

X.P. Ma, L.J. Wang, C.M. Liu, S.V. Subramanian, Mater. Sci. Eng. A 539 (2012) 271–279.

C.A.D. Rodrigues, R.M. Bandeira, B.B. Duarte, G. Tremiliosi-Filho, A.M. Junior Jr., Mater. Sci. Eng. A 650 (2016) 75–83.

D.N. Zou, Y. Han, W. Zhang, X.D. Fang, J. Iron Steel Res. Int. 17 (2010) No. 8, 50–54.

M. Schymura, R. Stegemann, A. Fischer, Int. J. Fatigue 79 (2015) 25–35.

Y. Song, X. Li, L. Rong, Y. Li, Mater. Sci. Eng. A 528 (2011) 4075–4079.

D. Xu, Y. Liu, Z. Ma, H. Li, Z. Yan, Int. J. Miner. Metall. Mater. 21 (2014) 279–288.

E. Taban, E. Kaluc, O.O. Ojo, Mater. Testing 58 (2016) 501–518.

A. Bojack, L. Zhao, P.F. Morris, J. Sietsma, Metall. Mater. Trans. A 47 (2016) 1996–2009.

N. Nakada, T. Tsuchiyama, S. Takaki, N. Miyano, ISIJ Int. 51 (2011) 299–304.

P.R. Howell, J.V. Bee, R.W.K. Honeycombe, Metall. Trans. A 10 (1979) 1213–1222.

Y. Song, X.Y. Li, L.J. Rong, D.H. Ping, F.X. Yin, Y.Y. Li, Mater. Lett. 64 (2010) 1411–1414.

J.D. Escobar, J.D. Poplawsky, G.A. Faria, J. Rodriguez, J.P. Oliveira, C.A.F. Salvador, P.R. Mei, S.S. Babu, A.J. Ramirez, Mater. Des. 140 (2018) 95–105.

J. Janovec, A. Vyrostkova, P. Sevc, J.S. Robinson, M. Svoboda, J. Krestankova, H.J. Grabke, Acta Mater. 51 (2003) 4025–4032.

T. Takeil, M. Yabe, A. Ooi, E. Tada, A. Nishikata, J. Electrochem. Soc. 166 (2019) C375–C381.

J.S. Armijo, B.E. Wilde, Corros. Sci. 9 (1968) 649–664.

Y. Song, D.H. Ping, F.X. Yin, X.Y. Li, Y.Y. Li, Mater. Sci. Eng. A 527 (2010) 614–618.

J.W. Liu, G.F. Li, D. Chen, Z.H. Chen, Chin. J. Aeronaut. 25 (2012) 931–936.

B.S. Amirkhiz, S. Xu, C. Scott, Materialia 6 (2019) 100330.

Z.F Xu, Z.M. Ding, L.N. Dong, B. Liang, Metall. Mater. Trans. A 47 (2016) 4862–4868.

E. Vincent, C.S. Becquart, C. Domain, Nucl. Instrum. Methods Phys. Res. Sect. B 228 (2005) 137–141.

M. Yoshida, Scripta Metall. 16 (1982) 787–790.

J.Z. Wang, Z.D. Liu, S.H. Bao, S.C. Cheng, J. Iron Steel Res. Int. 20 (2013) No. 10, 113–121.

X. Lei, Y. Feng, J. Zhang, A. Fu, C. Yin, D.D. Macdonald, Electrochim. Acta 191 (2016) 640–650.

T.J. Mesquita, E. Chauveau, M. Mantel, N. Bouvier, D. Koschel, Corros. Sci. 81 (2014) 152–161.

L. Cho, L. Golem, E.J. Seo, D. Bhattacharya, J.G. Speer, K.O. Findley, J. Alloy. Compd. 846 (2020) 156349.

Acknowledgements

The authors gratefully acknowledge the financial support received from the Central Iron and Steel Research Institute and the Research Center for Analysis and Measurement of Kunming University of Science and Technology (No. 2017M20152230069).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

He, X., Lü, Xy., Wu, Zw. et al. M23C6 precipitation and Si segregation promoted by deep cryogenic treatment aggravating pitting corrosion of supermartensitic stainless steel. J. Iron Steel Res. Int. 28, 629–640 (2021). https://doi.org/10.1007/s42243-020-00514-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00514-w