Abstract

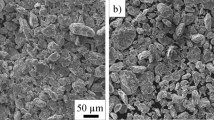

Ferritic steel with oxide dispersion strengthening is a promising material for fusion and fission reactor components. In the present study, the influence of Mo, V, and Zr on microstructural evolution, thermal stability, and mechanical properties of yttria-dispersed ferritic Fe-14Cr-1Ti-0.25Y2O3-0.3 wt pct X (X = Mo/V/Zr) steels was investigated. This work is inspired by the concept of MA957 alloy, where Mo was replaced by V/Zr to develop new alloy compositions with possible improvement of thermal stability and mechanical properties through grain refinement and oxide dispersion strengthening. These steels were developed by mechanical alloying (MA) and subsequently consolidated by spark plasma sintering (SPS) at different temperatures (900 °C, 1000 °C, and 1050 °C) in high-purity argon atmosphere. The relative sintered density was found to be ~ 97 to 98 pct for specimens spark plasma sintered (SPSed) at 1050 °C. Microstructural analysis of the SPSed specimens (using scanning electron microscopy/transmission electron microscopy-selected area diffraction (SEM/TEM-SAED)) confirmed the formation of uniformly dispersed Y-Ti-O, TiO, and Ti-Cr-O nanosize complex oxide particles within the ultrafine ferritic matrix grains (~ 200 nm). The nanoindentation hardness value is found to correlate well with the compressive strength and wear resistance of the corresponding batches. The influence of V addition in Fe-14Cr-1Ti-0.25Y2O3 alloy is established to yield better thermal stability and superior mechanical properties (nanoindentation hardness of 16.7 GPa, compressive strength of 3068 MPa) as compared to Mo/Zr-stabilized alloys. This was analyzed and discussed in terms of microstructural evolution and strengthening mechanisms involved in comparison to the Mo/Zr-added steels.

Similar content being viewed by others

References

1.D. Gosset: Structural Materials for Generation IV Nuclear Reactors, Elsevier, Amsterdam, 2017, pp. 533–67.

2.C.R.F. Azevedo: Eng. Fail. Anal., 2011, vol. 18, pp. 1943–62.

3.K.L. Murty and I. Charit: J. Nucl. Mater., 2008, vol. 383, pp. 189–95.

4.A. Hojná: Metals (Basel), 2017, vol. 7, p. 392.

5.V.M.S. Muthaiah, L.H. Babu, C.C. Koch, and S. Mula: Mater. Charact., 2016, vol. 114, pp. 43–53.

6.Y. Miao, K. Mo, B. Cui, W.Y. Chen, M.K. Miller, K.A. Powers, V. McCreary, D. Gross, J. Almer, I.M. Robertson, and J.F. Stubbins: Mater. Charact., 2015, vol. 101, pp. 136–43.

7.G.R. Odette: Scripta Mater., 2018, vol. 143, pp. 142–48.

8.S.J. Zinkle, J.L. Boutard, D.T. Hoelzer, A. Kimura, R. Lindau, G.R. Odette, M. Rieth, L. Tan, and H. Tanigawa: Nucl. Fus., 2017, vol. 57, p. 17.

9.W.Z. Xu, L.L. Li, M. Saber, C.C. Koch, Y.T. Zhu, and R.O. Scattergood: J. Nucl. Mater., 2014, vol. 452, pp. 434–39.

X.M. Bai, A.F. Voter, R.G. Hoagland, M. Nastasi, and B.P. Uberuaga: Science, 2010, vol. 327, pp. 1631–34.

11.D. Chen, J. Wang, T. Chen, and L. Shao: Sci. Rep., 2013, vol. 3, pp. 1–5.

12.S. Ukai, T. Kaito, S. Ohtsuka, T. Narita, M. Fujiwara, and T. Kobayashi: ISIJ Int., 2003, vol. 43, pp. 2038–45.

13.C. Cayron, E. Rath, I. Chu, and S. Launois: J. Nucl. Mater., 2004, vol. 335, pp. 83–102.

14.S. Ukai, M. Harada, H. Okada, M. Inoue, S. Nomura, S. Shikakura, K. Asabe, T. Nishida, and M. Fujiwara: J. Nucl. Mater., 1993, vol. 204, pp. 65–73.

15.S. Ohtsuka, S. Ukai, M. Fujiwara, T. Kaito, and T. Narita: J. Phys. Chem. Solids, 2005, vol. 66, pp. 571–75.

16.X. Zhou, C. Li, L. Yu, H. Li, and Y. Liu: Fus. Eng. Des., 2018, vol. 135, pp. 88–94.

17.T. Jaumier, S. Vincent, L. Vincent, and R. Desmorat: J. Nucl. Mater., 2019, vol. 518, pp. 274–86.

18.R. Xie, Z. Lu, C. Lu, Z. Li, X. Ding, and C. Liu: Fus. Eng. Des., 2017, vol. 115, pp. 67–73.

19.W. Li, H. Xu, X. Sha, J. Meng, W. Wang, C. Kang, X. Zhang, and Z. Wang: Fus. Eng. Des., 2018, vol. 137, pp. 71–78.

20.V. Mihalache, I. Mercioniu, A. Velea, and P. Palade: Powder Technol., 2019, vol. 347, pp. 103–13.

21.A. García‐Junceda, E. Macía, D. Garbiec, M. Serrano, J.M. Torralba, and M. Campos: Metals (Basel), 2020, vol. 10, p. 348.

22.S.S. Mishra, D. Chaira, and S.K. Karak: Ceram. Int., 2019, vol. 45, pp. 20555–20565.

23.I. Hilger, X. Boulnat, J. Hoffmann, C. Testani, F. Bergner, Y. De Carlan, F. Ferraro, and A. Ulbricht: J. Nucl. Mater., 2016, vol. 472, pp. 206–14.

24.M. Goto, S.Z. Han, T. Yamamoto, J. Kitamura, J.H. Ahn, T. Yakushiji, S.S. Kim, and J. Lee: Int. J. Fatigue, 2016, vol. 92, pp. 577–87.

25.M. Goto, T. Yamamoto, S.Z. Han, S. Kim, J. Kitamura, T. Yakushiji, J.-H. Ahn, R. Takanami, T. Utsunomiya, and J. Lee: Int. J. Fatigue, 2020, vol. 142, p. 105978.

26.D. Roy, R. Mitra, T. Chudoba, Z. Witczak, W. Lojkowski, H.J. Fecht, and I. Manna: Mater. Sci. Eng. A, 2008, vol. 497, pp. 93–100.

27.S. Bera, W. Lojkowsky, and I. Manna: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 3276–83.

S.S. Singh, D. Roy, R. Mitra, R.V. SubbaRao, R.K. Dayal, B. Raj, and I. Manna: Mater. Sci. Eng. A, 2009, vol. 501, pp. 242–47.

29.Z.Y. Hu, Z.H. Zhang, X.W. Cheng, F.C. Wang, Y.F. Zhang, and S.L. Li: Mater. Des., 2020, vol. 191, p. 108662.

30.S.R. Oke, O.O. Ige, O.E. Falodun, A.M. Okoro, M.R. Mphahlele, and P.A. Olubambi: Int. J. Adv. Manuf. Technol., 2019, vol. 102, pp. 3271–90.

31.M. Omori: Mater. Sci. Eng. A, 2000, vol. 287, pp. 183–88.

32.Q. Zhao, Z. Qiao, Y. Liu, L. Yu, Y. Huang, Q. Guo, and H. Li: Metals (Basel), 2019, vol. 9, p. 200.

33.S. Abbasi and A. Shokuhfar: J. Iron Steel Res. Int., 2007, vol. 14, pp. 74–78.

34.H. Dong, L. Yu, Y. Liu, C. Liu, H. Li, and J. Wu: Fus. Eng. Des., 2017, vol. 125, pp. 402–06.

35.S. Sooraj, V.M.S. Muthaiah, P.C. Kang, C.C. Koch, and S. Mula: Philos. Mag., 2016, vol. 96, pp. 2649–70.

36.V.M.S. Muthaiah and S. Mula: Mater. Sci. Eng. A, 2019, vol. 739, pp. 367–76.

37.C. Suryanarayana and M.G. Norton: X-Ray Diffraction, Springer, New York, NY, 1998.

38.C. Suryanarayana: Progr. Mater. Sci., 2001, vol. 46, pp. 1–184.

39.P. Susila, D. Sturm, M. Heilmaier, B.S. Murty, and V. Subramanya Sarma: Mater. Sci. Eng. A, 2011, vol. 528, pp. 4579–84.

40.M.B. Shongwe, S. Diouf, M.O. Durowoju, and P.A. Olubambi: J. Alloys Compd., 2015, vol. 649, pp. 824–32.

41.V.M.S. Muthaiah and S. Mula: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 990–1005.

X. Boulnat: Ph.D. Dissertation, INSA, Lyon, 2012.

44.M.J. Alinger, G.R. Odette, and D.T. Hoelzer: J. Nucl. Mater., 2004, vols. 329–333, pp. 382–86.

45.T. Okuda and M. Fujiwara: J. Mater. Sci. Lett., 1995, vol. 14, pp. 1600–03.

46.S. Ukai and M. Fujiwara: J. Nucl. Mater., 2002, vols. 307–311, pp. 749–57.

47.L. Toualbi, M. Ratti, G. André, F. Onimus, and Y. De Carlan: J. Nucl. Mater., 2011, vol. 417, pp. 225–28.

48.Y. Kimura, S. Takaki, S. Suejima, R. Uemori, and H. Tamehiro: ISIJ Int., 1999, vol. 39, pp. 176–82.

49.L. Dai, Y. Liu, and Z. Dong: Powder Technol., 2012, vol. 217, pp. 281–87.

50.T. Liu, H. Shen, C. Wang, and W. Chou: Progr. Nat. Sci. Mater. Int., 2013, vol. 23, pp. 434–39.

51.P.K. Parida, A. Dasgupta, K. Jayasankar, M. Kamruddin, and S. Saroja: J. Nucl. Mater., 2013, vol. 441, pp. 331–36.

52.S.K. Karak, J.D. Majumdar, W. Lojkowski, A. Michalski, L. Ciupinski, K.J. Kurzydowski, and I. Manna: Philos. Mag., 2012, vol. 92, pp. 516–34.

53.H. Zhang, Y. Huang, H. Ning, C.A. Williams, A.J. London, K. Dawson, Z. Hong, M.J. Gorley, C.R.M. Grovenor, G.J. Tatlock, S.G. Roberts, M.J. Reece, H. Yan, and P.S. Grant: J. Nucl. Mater., 2015, vol. 464, pp. 61–68.

A. Claisse and P. Olsson: Nucl. Instrum. Meth. Phys. Res, 2013, vol. 303, pp. 18–22.

55.H. Sakasegawa, F. Legendre, L. Boulanger, M. Brocq, L. Chaffron, T. Cozzika, J. Malaplate, J. Henry, and Y. De Carlan: J. Nucl. Mater., 2011, vol. 417, pp. 229–32.

56.N. Sallez, C. Hatzoglou, F. Delabrouille, D. Sornin, L. Chaffron, M. Blat-Yrieix, B. Radiguet, P. Pareige, P. Donnadieu, and Y. Bréchet: J. Nucl. Mater., 2016, vol. 472, pp. 118–26.

57.S. Yamashita, S. Ohtsuka, N. Akasaka, S. Ukai, and S. Ohnuki: Philos. Mag. Lett., 2004, vol. 84, pp. 525–29.

58.S. Pasebani, I. Charit, Y.Q. Wu, D.P. Butt, and J.I. Cole: Acta Mater., 2013, vol. 61, pp. 5605–17.

59.B. Srinivasarao, K. Oh-ishi, T. Ohkubo, and K. Hono: Acta Mater., 2009, vol. 57, pp. 3277–86.

E. Broitman: Tribol. Lett., 2017, 65, vol. 65.

C. OnChui and K.C. Saraswat: Germanium-Based Technologies, Elsevier, Amsterdam, 2007, pp. 295–361.

62.R. Gao, T. Zhang, X.P. Wang, Q.F. Fang, and C.S. Liu: J. Nucl. Mater., 2014, vol. 444, pp. 462–68.

63.P. Dou, A. Kimura, R. Kasada, T. Okuda, M. Inoue, S. Ukai, S. Ohnuki, T. Fujisawa, and F. Abe: J. Nucl. Mater., 2014, vol. 444, pp. 441–53.

64.T. Liu, L. Wang, C. Wang, H. Shen, and H. Zhang: Mater. Des., 2015, vol. 88, pp. 862–70.

O. Vingsbo, A.R. Massih, and S. Nilsson: J. Tribol., 1996, vol. 118.

66.J.H. Sung, T.H. Kim, and S.S. Kim: Wear, 2001, vols. 250–251, pp. 658–64.

S.K. Karak, C.S. Vishnu, Z. Witczak, W. Lojkowski, J. DuttaMajumdar, and I. Manna: Wear, 2010, vol. 270, pp. 5–11.

68.S. Gupta, S.K. Sharma, B.V.M. Kumar, and Y.W. Kim: Ceram. Int., 2015, vol. 41, pp. 14780–14789.

69.R.V. Kurahatti, A.O. Surendranathan, A.V.R. Kumar, C.S. Wadageri, V. Auradi, and S.A. Kori: Proc. Mater. Sci., 2014, vol. 5, pp. 274–80.

70.F.H. Stott and G.C. Wood: Tribol. Int., 1978, vol. 11, pp. 211–18.

71.F.H. Stott, J. Glascott, and G.C. Wood: Wear, 1985, vol. 101, pp. 311–24.

72.L. Wang and D.Y. Li: Wear, 2003, vol. 255, pp. 535–44.

73.H. Cui, J. Guo, Y. Su, H. Ding, W. Bi, X. Li, and H. Fu: Mater. Sci. Eng. A, 2007, vol. 448, pp. 49–55.

Acknowledgments

The authors greatly appreciate the Metallurgical and Materials Engineering Department and Institute Instrumentation Centre, IIT Roorkee, for providing the facilities and support while we carried out this research work. This research was not supported by any specific grant from any funding agency in either the public, commercial, or not-for-profit sector.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 30, 2020; accepted November 2, 2020.

Rights and permissions

About this article

Cite this article

Paul, M.J., Muthaiah, V.M.S. & Mula, S. Yttria-Reinforced Fe-Cr Ferritic Alloy-Based Nanocomposites for Fusion Reactor Structural Applications. Metall Mater Trans A 52, 627–643 (2021). https://doi.org/10.1007/s11661-020-06102-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06102-7