Abstract

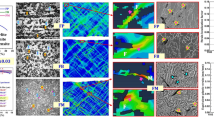

This paper attempts to predict how the microstructural features and mechanical properties of the individual constituents affect the deformation behavior and formability of ferrite-pearlite steels under quasi-static loading at room temperature. For this purpose, finite element simulations using representative volume elements (RVEs) based on the real microstructures were implemented to model the flow behavior of the ferrite-pearlite steels with various microstructural morphologies (non-banded and banded). The homogenized flow curves obtained from the RVEs subjected to periodic boundary conditions together with displacement boundary conditions were validated with the experimental results of the uniaxial tensile tests. Then, the initial microstructural inhomogeneity and Johnson–Cook damage criteria were employed for both non-banded and banded RVEs to estimate the onset of plastic instability under different loading paths ranging from uniaxial tension to equi-biaxial tension. Finally, the forming limit diagrams of both ferritic-pearlitic microstructures were predicted, which show a good agreement with the experimental results of the Nakazima stretch-forming tests (less than 13 pct error). It implies that the initial microstructural inhomogeneity criterion adequately enables to predict the plastic instability in the ferritic-pearlitic steel sheets without using any damage or failure criterion. The most commonly observed damage mechanism is the severe plastic deformation of the ferrite grains near the pearlite colonies due to the strength contrast between ferrite and pearlite. Another significant finding is that the microstructural morphology has a crucial influence on the strain partitioning, strain localization, and formability of the ferritic-pearlitic steels.

Similar content being viewed by others

References

H. K. D. H. Bhadeshia and R. W. K. Honeycombe: Steels: Microstructure and Properties, 4th ed., Butterworth-Heinemann, Oxford, 2017, pp. 59-100.

W. D. Callister and D. G. Rethwisch: Materials Science and Engineering: An Introduction, 10th ed., John Wiley & Sons, New York, 2018, pp. 392-449.

G. J. Shiflet: Pearlite, Encyclopedia of Materials: Science and Technology, 1st ed., Elsevier, Amsterdam, 2001, pp. 6783-88.

J. D. Verhoeven: J. Mater. Eng. Perform, 2000, vol. 9, pp. 286-96.

R. Großterlinden, R. Kawalla, U. Lotter and H. Pircher: Steel Res., 1992, vol. 63, pp. 331-36.

T. F. Majka, D. K. Matlock and G. Krauss: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1627–37.

H. Farahani, W. Xu and S. van der Zwaag: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 1998–2010.

G. Krauss: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 781-92.

S. E. Offerman, N. H. van Dijk, M. T. Rekveldt, J. Sietsma and S. van der Zwaag: Mater. Sci. Technol., 2002, vol. 18, pp. 297-303.

X. Zhang, Y. Wang, J. Yang, Z. Qiao, C. Ren and C. Chen: Opt. Laser Eng., 2016, vol. 85, pp. 24-28.

D. Rèche, J. Besson, T. Sturel, X. Lemoine and A. F. Gourgues-Lorenzon: Int. J. Mech. Sci., 2012, vol. 57, pp. 43–53.

D. Rèche, T. Sturel, O. Bouaziz, A. Col and A. F. Gourgues-Lorenzona: Mater. Sci. Eng. A, 2011, vol. 528, pp. 5241-50.

A. J. Kaijalainen, P. Suikkanen, L. P. Karjalainen and J. J. Jonas: Metall. Mater. Trans. A, 2014, vol. 45, pp. 1273-83.

F. M. Al-Abbasi: Mech. Mater., 2013, vol. 63, pp. 48-64.

G. Laschet, P. Fayek, T. Henke, H. Quade and U. Prahl: Mat. Sci. Eng. A, 2013, vol. 566, pp. 143-56.

R. Rodriguez and I. Gutierrez: Mater. Sci. Forum, 2003, Vols. 426-432, pp. 4525-30.

I. Gutierrez: Metalurgija, 2012, vol. 11, pp. 201-14.

B. Berisha, C. Raemy, C. Becker, M. Gorji and P. Hora: Acta Mater., 2015, vol. 100, pp. 191-201.

L. Wang, D. Tang and Y. Song: Iron. Steel Res. Int., 2017, vol. 24, pp. 321-27.

[20] D. Banabic: Multiscale Modelling in Sheet Metal Forming, 1st ed., Springer, Switzerland, 2016, pp. 205-300.

H. Noori and R. Mahmudi: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 2040–52.

E. M. Viatkina, W. A. M. Brekelmans and M. G. D. Geers: J. Mater. Process., 2005, vol. 168, pp. 211-18.

H. P. Gänser, E. Werner and F. Fischer: Int. J. Mech. Sci., 2000, vol. 42, pp. 2041-54.

R. Wesenjak, C. Krempaszky and E. Werner: Comput. Mater. Sci., 2016, vol. 111, pp. 277–88.

X. Duan, M. Jain and D. S. Wilkinson: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 3489-501.

V. Uthaisangsuk, U. Prahl and W. Bleck: Eng. Fract. Mech., 2011, vol. 78, pp. 469-86.

W. M. Mohammed and E. N. M. A. Elbestawi: J. Manuf. Sci. Tec., 2012, vol. 5, pp. 87-101.

Z. Li, R. Kiran, J. Hu, L. G. Hector Jr and A. F. Bower: Int. J. Fract., 2020, vol. 221, pp. 53–85.

M. Murugesan and D. W. Jung: Materials, 2019, vol. 12, p. 609.

N. Ayachi, N. Guermazi, C. H. Pham and P. -Y. Manach: Metals, 2020, vol. 10, p. 1163.

X. Hu, P. V. Houtte, M. Liebeherr, A. Walentek, M. Seefeldt and H. Vandekinderen: Acta Mater., 2006, vol. 54, pp. 1029-40.

ASTM E112 – 13: Standard Test Methods for Determining Average Grain Size, ASTM International, West Conshohocken, PA, 2013.

M. Hajian and A. Assempour: Int. J. Adv. Manuf. Technol., 2015, vol. 76, pp. 1757–67.

A. Ghazanfari and A. Assempour: Mater. Des., 2012, vol. 34, pp. 185–91.

W. Choi, P. P. Gillis and S. E. Jones: Metall. Trans. A, 1989, vol. 20A, pp. 1975-88.

National Institute of Standards and Technology (NIST):OOF: Finite Element Analysis of Microstructures, https://www.ctcms.nist.gov/oof/oof2/.

S. L. Omairey, P. D. Dunning and S. Sriramula: Eng.Comput., 2019, vol. 35, pp. 567–77.

Z. Xia, Y. Zhang and F. Ellyin: Int. J. Solids Struct., 2003, vol. 40, pp. 1907-21.

G. R. Johnson and W. H. Cook: Eng. Fract. Mech., 1985, vol. 21, pp. 31-48.

M. Murugesan and D. W. Jung: Materials, 2019, vol. 12, pp. 1-18.

G. H. Majzoobi and F. Rahimi-Dehgolan. Procedia Eng., 2011, 10: 764–73.

M. Ohata, M. Suzuki, A. Ui and F. Minami: Eng. Fract. Mech., 2010, vol. 77, pp. 277-84.

Z. Marciniak and K. Kuczyński: Int. J. Mech. Sci., 1967, vol. 9, pp. 609-12.

L. Chuzhoy, R. E. DeVor, S. G. Kapoor and D. J. Bammann: J. Manuf. Sci. Eng., 2002, vol. 124, pp. 162-69.

G. Ljustina, M. Fagerström and R. Larsson: Eur. J. Mech. A-Solids, 2013, vol. 37, pp. 57-68.

H. Qiu, T. Inoue and R. Ueji: Metals, 2020, vol. 10, p. 530.

Z. Zhang and Y. Liao: Metall. Mater. Trans. A, 2016, vol. 47, pp. 1621–28.

A. Ramazani, H. Quade, M. Abbasi and U. Prahl: Mat. Sci. Eng. A, 2016, vol. 651, pp. 160–64.

D. S. Connolly, C. P. Kohar, W. Muhammad, L. G. Hector Jr., R. K. Mishra and K. Inal: Int. J. Plast., 2020, vol. 133, p. 102757.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted on June 19, 2020, accepted November 24, 2020.

Rights and permissions

About this article

Cite this article

Isavand, S., Assempour, A. Effects of Microstructural Morphology on Formability, Strain Localization, and Damage of Ferrite-Pearlite Steels: Experimental and Micromechanical Approaches. Metall Mater Trans A 52, 711–725 (2021). https://doi.org/10.1007/s11661-020-06115-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06115-2