Abstract

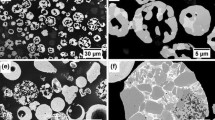

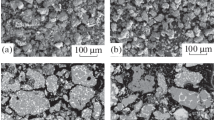

Despite the existence of several methods for production of superhydrophobic coatings from various materials, their application in harsh environments is still a great challenge. In this work, WC-Co-Cr cermet coatings were prepared by means of high velocity oxy-fuel (HVOF) spraying. WC particles dispersed in Co-Cr metallic matrix allowed to form the multi-scale surface roughness and thus to achieve hydrophobicity of the coatings in the as-sprayed state. The additional surface treatment by the silicone oil rendered the coatings superhydrophobic. The WC-Co-Cr coatings were fabricated from three different powder feedstocks: coarse powder with coarse WC particles, coarse powder with ultrafine WC particles, and fine powder with ultrafine WC particles. The investigation of microstructure, phase composition, and surface topography of produced coatings was conducted to study the influence of these factors on the water contact angle and surface free energy, which were obtained by the sessile droplet method. Theoretical models were used to explain the wetting behavior of all the coatings. Finally, preliminary results of the slurry abrasion response test revealed very good robustness of hydrophobicity of the coatings and also pointed to a need for further research on surface modifications for sacrificial applications.

adapted from (Ref 25)

Similar content being viewed by others

References

Y. Yuan and T.R. Lee, Contact Angle and Wetting Properties, Surface Science Techniques Springer Series in Surface Sciences, Vol 51, G. Bracco and B. Holst, Ed., Springer, Berlin, 2013,

A. Lafuma and D. Quéré, Superhydrophobic States, Nat. Mater., 2003, 2, p 457-460. https://doi.org/10.1038/nmat924

J. Drelich and E. Chibowski, Superhydrophilic and Superwetting Surfaces: Definition and Mechanisms of Control, Langmuir, 2010, 26(24), p 18621-18623. https://doi.org/10.1021/la1039893

T. Young, An Essay to the Cohesion of Fluids, Philoshopical Trans. R. Soc. London., 1804, 95, p 65-87. https://doi.org/10.1098/rstb.1983.0080

R.N. Wenzel, Resistance of Solid Surfaces to Wetting by Water, Ind. Eng. Chem., 1936, 28(8), p 988-994. https://doi.org/10.1021/ie50320a024

B.D. Cassie, A.B.D. Cassie, and S. Baxter, Of Porous Surfaces, Trans. Faraday Soc., 1944, 40, p 546-551. https://doi.org/10.1039/tf9444000546

T. Nishino, M. Meguro, K. Nakamae, M. Matsushita, and Y. Ueda, The Lowest Surface free Energy Based on -CF3 Alignment, Langmuir, 1999, 15(13), p 4321-4323. https://doi.org/10.1021/la981727s

Y.Y. Yan, N. Gao, and W. Barthlott, Mimicking Natural Superhydrophobic Surfaces and Grasping the Wetting Process: A Review on Recent Progress in Preparing Superhydrophobic Surfaces, Adv. Colloid Interface Sci., 2011, 169(2), p 80-105. https://doi.org/10.1016/j.cis.2011.08.005

L.B. Boinovich and A.M. Emelyanenko, Hydrophobic Materials and Coatings: Principles of Design, Properties and Applications, Russ. Chem. Rev., 2008, 77(7), p 583-600. https://doi.org/10.1070/RC2008v077n07ABEH003775

J. Drelich, E. Chibowski, D.D. Meng, and K. Terpilowski, Hydrophilic and Superhydrophilic Surfaces and Materials, Soft Matter, 2011, 7, p 9804-9828. https://doi.org/10.1039/c1sm05849e

J. Genzer and K. Efimenko, Recent Developments in Superhydrophobic Surfaces and Their Relevance to Marine Fouling: A Review, Biofouling, 2006, 22(5), p 339-360. https://doi.org/10.1080/08927010600980223

K. Liu and L. Jiang, Bio-Inspired Self-Cleaning Surfaces, Annu. Rev. Mater. Res., 2012, 42(1), p 231-263. https://doi.org/10.1146/annurev-matsci-070511-155046

R. Blossey, Self-Cleaning Surfaces—Virtual Realities, Nat. Mater., 2003, 2, p 301-306. https://doi.org/10.1038/nmat856

M. Zhang, C. Wang, S. Wang, and J. Li, Fabrication of Superhydrophobic Cotton Textiles for Water–Oil Separation Based on Drop-Coating Route, Carbohydr. Polym., 2013, 97(1), p 59-64. https://doi.org/10.1016/j.carbpol.2012.08.118

J.B. Boreyko and C.-H. Chen, Self-Propelled Dropwise Condensate on Superhydrophobic Surfaces, Phys. Rev. Lett., 2009, 103(18), p 184501. https://doi.org/10.1103/PhysRevLett.103.184501

K.M. Wisdom, J.A. Watson, X. Qu, F. Liu, G.S. Watson, and C.-H. Chen, Self-Cleaning of Superhydrophobic Surfaces by Self-Propelled Jumping Condensate, Proc. Natl. Acad. Sci., 2013, 110(20), p 7992-7997. https://doi.org/10.1073/pnas.1210770110

H. Koivuluoto, E. Hartikainen, and H. Niemela-Anttonen, Thermally Sprayed Coatings: Novel Surface Enrgineering Strategy Towards Icephobic Solutions, Materials, 2020, 13(6), p 1434. https://doi.org/10.3390/ma13061434

H. Sojoudi, M. Wang, N.D. Boscher, G.H. McKinley, and K.K. Gleason, Durable and Scalable Icephobic Surfaces: Similarities and Distinctions From Superhydrophobic Surfaces, Soft Matter, 2016, 12, p 1938-1963. https://doi.org/10.1039/C5SM02295A

Q. Xu, J. Li, J. Tian, J. Zhu, and X. Gao, Energy-Effective Frost-Free Coatings Based on Superhydrophobic Aligned Nanocones, ACS Appl. Mater. Interfaces., 2014, 6(12), p 8976-8980. https://doi.org/10.1021/am502607e

T. Moriya, K. Manabe, M. Tenjimbayashi, K. Suwabe, H. Tsuchiya, T. Matsubayashi, W. Navarrini, and S. Shiratori, A Superrepellent Coating with Dynamic Fluorine Chains for Frosting Suppression: Effects of Polarity, Coalescence and Ice Nucleation Free Energy Barrier, RSC Adv., 2016, 6, p 92197-92205. https://doi.org/10.1039/C6RA18483A

Gh Barati Darband, M. Aliofjhazraei, S. Khorsand, S. Sokhanvar, and A. Kaboli, Science and Engineering of Superhydrophobic Surfaces: Review of Corrosion Resistance, Chemical and Mechanical Stability, Arab. J. Chem., 2020, 13(1), p 1763-1802. https://doi.org/10.1016/j.arabjc.2018.01.013

C. Lee and C.-J. Kim, Underwater Restoration and Retention of Gases on Superhydrophobic Surfaces for Drag Reduction, Phys. Rev. Lett., 2011, 106(1), p 014502. https://doi.org/10.1103/PhysRevLett.106.014502

A.M. Emelyanenko, F.M. Shagieva, A.G. Domantovsky, and L.B. Boinovich, Nanosecond laser Micro- and Nanotexturing for the Design of a Superhydrophobic Coating Robust Against Long-Term Contact With Water, Cavitation, and Abrasion, Appl. Surf. Sci., 2015, 332, p 513-517. https://doi.org/10.1016/j.apsusc.2015.01.202

Y. Tian and L. Jiang, Intrinsically Robust Hydrophobicity, Nat. Mater., 2013, 12, p 291-292. https://doi.org/10.1038/nmat3610

P. Komarov, L. Čelko, M. Remešová, K. Skorokhod, D. Jech, L. Klakurková, K. Slámečka and R. Mušálek, The role of microstructure on wettability of plasma sprayed yttria stabilized zirconia coatings, in: Met. 2017 - 26th Int. Conf. Metall. Mater., TANGER Ltd, 2017: pp. 1116–1121.

K. Koch, B. Bhushan, Y.C. Jung, and W. Barthlott, Fabrication of Artificial Lotus Leaves and Significance of Hierarchical Structure For Superhydrophobicity and Low Adhesion, Soft Matter, 2009, 5, p 1386. https://doi.org/10.1039/b818940d

T. Verho, C. Bower, P. Andrew, S. Franssila, O. Ikkala, and R.H.A. Ras, Mechanically Durable Superhydrophobic Surfaces, Adv. Mater., 2011, 23(5), p 673-678. https://doi.org/10.1002/adma.201003129

N. Sharifi, M. Pugh, C. Moreau, and A. Dolatabadi, Developing Hydrophobic and Superhydrophobic TiO2 Coatings by Plasma Spraying, Surf. Coat. Technol., 2016, 289, p 29-36. https://doi.org/10.1016/j.surfcoat.2016.01.029

L. Hu, X. Song, D. Jin, C. Xing, X. Shan, X. Zhao, F. Guo, and P. Xiao, A Robust Quasi-Superhydrophobic Ceria Coating Prepared Using Air-Plasma Spraying, J. Am. Ceram. Soc., 2019, 102(3), p 1386-1393. https://doi.org/10.1111/jace.16005

P. Xu, T.W. Coyle, L. Pershin, and J. Mostaghimi, Fabrication of Micro-/Nano-Structured Superhydrophobic Ceramic Coating with Reversible Wettability Via A Novel Solution Precursor Vacuum Plasma Spray Process, Mater. Des., 2018, 160, p 974-984. https://doi.org/10.1016/j.matdes.2018.10.015

P. Xu, T.W. Coyle, L. Pershin, and J. Mostaghimi, Understanding the Correlations Between the Mechanical Robustness, Coating Structures and Surface Composition for Highly-/Super-Hydrophobic Ceramic Coatings, Surf. Coat. Technol., 2019, 378, p 124929. https://doi.org/10.1016/j.surfcoat.2019.124929

N. Xi, Y. Liu, X. Zhang, N. Liu, H. Fu, Z. Hang, G. Yang, H. Chen, and W. Gao, Steady Anti-Icing Coatings on Weathering Steel Fabricated by HVOF Spraying, Appl. Surf. Sci., 2018, 444, p 757-762. https://doi.org/10.1016/j.apsusc.2018.03.075

J. Qiao, L. Na Zhu, W. Yue, Z. Qiang Fu, J. Jie Kang, and C. Biao Wang, The Effect of Attributes of Micro-Shapes of Laser Surface Texture on the Wettability of WC-CrCo Metal Ceramic Coatings, Surf. Coat. Technol., 2018, 334, p 429-437. https://doi.org/10.1016/j.surfcoat.2017.12.001

S. Vijay, L. Wang, C. Lyphout, P. Nylen, and N. Markocsan, Surface Characteristics Investigation of HVAF Sprayed Cermet Coatings, Appl. Surf. Sci., 2019, 493, p 956-962. https://doi.org/10.1016/j.apsusc.2019.07.079

P. Komarov, L. Čelko, D. Jech, M. Papula, K. Slámečka, M. Horynová, L. Klakurková, and J. Kaiser, Investigations of Wettability of Wear Resistant Coatings Produced by Atmospheric Plasma Spraying, Solid State Phenom., 2017, 270, p 230-235. https://doi.org/10.4028/www.scientific.net/SSP.270.230

J. Pulsford, S. Kamnis, J. Murray, M. Bai, and T. Hussain, Effect of Particle and Carbide Grain Sizes on a HVOAF WC-Co-Cr Coating for the Future Application on Internal Surfaces: Microstructure and Wear, J. Therm. Spray Technol., 2018, 27, p 207-219. https://doi.org/10.1007/s11666-017-0669-8

H. Wang, M. Gee, Q. Qiu, H. Zhang, X. Liu, H. Nie, X. Song, and Z. Nie, Grain size Effect on Wear Resistance of WC-Co Cemented Carbides Under Different Tribological Conditions, J. Mat. Sci. Tech., 2019, 35, p 2435-2446. https://doi.org/10.1016/j.jmst.2019.07.016

J.M. Guilemany, S. Dosta, and J.R. Miguel, The Enhancement of the Properties of WC-Co HVOF Coatings Through the Use of Nanostructured and Microstructured Feedstock Powders, Surf. Coat. Technol., 2006, 201(3–4), p 1180-1190. https://doi.org/10.1016/j.surfcoat.2006.01.041

A. Lekatou, D. Sioulas, A.E. Karantzalis, and D. Grimanelis, A Comparative Study on the Microstructure and Surface Property Evaluation of Coatings Produced from Nanostructured and Conventional WC-Co Powders HVOF-Sprayed on Al7075, Surf. Coat. Technol., 2015, 276, p 539-556. https://doi.org/10.1016/j.surfcoat.2015.06.017

B. Yin, H.D. Zhou, D.L. Yi, J.M. Chen, and F.Y. Yan, Microsliding Wear Behaviour of HVOF Sprayed Conventional and Nanostructured WC-12Co Coatings at Elevated Temperatures, Surf. Eng., 2013, 26(6), p 469-477. https://doi.org/10.1179/026708410X12506870724352

A. Larson, R. Dreele, General Structure Analysis System (GSAS). LAUR 86–748. https://doi.org/10.https://11bm.xray.aps.anl.gov/documents/GSASManual.pdf, 2004 (accessed 31 July 2020).

J.A.R. Wesmann and N. Espallargas, Elucidating the Complex Role of Surface Oxides Formed During Sliding of self0mated Warm Sprayed WC-CoCr in Different Environments, Trib. Int., 2016, 94, p 360-372. https://doi.org/10.1016/j.triboint.2015.09.043

J.A.R. Wesmann, S. Kuroda, and N. Espallargas, The Role of Oxide Tribofilms on Friction and Wear of Different Thermally Sprayed WC-CoCr, J. Therm. Spray Technol., 2017, 26, p 492-502. https://doi.org/10.1007/s11666-017-0522-0

L.-N. Zhang, Y.-Y. Ma, Z.-L. Lang, Y.-H. Wang, S.U. Khan, G. Yan, H.-Q. Tan, H.-Y. Zang, and Y.-G. Li, Ultrafine Cable-Like WC/W2C Heterojunction Nanowires Covered by Graphitic Carbon Towards Highly Efficient Electrocatalytic Hydrogen Evolution, J. Mater. Chem. A, 2018, 6, p 15395-15403. https://doi.org/10.1039/C8TA05007D

J.A. Picas, M. Punset, E. Ruperez, S. Menargues, E. Martin, and M.T. Baile, Corrosion Mechanism of HVOF Thermal Sprayed WC-CoCr Coatings in Acidic Chloride Media, Surf. Coat. Technol., 2019, 371, p 378-388. https://doi.org/10.1016/j.surfcoat.2018.10.025

Z. Chen, W. Gong, S. Cong, Z. Wang, G. Song, T. Pan, X. Tang, J. Chen, W. Lu, and Z. Zhao, Eutectoid-Structured WC/W2C Heterostructures: A New Platform for Long-Term Alkaline Hydrogen Evolution Reaction at Low Overpotentials, Nano Energy, 2020, 68, p 104335. https://doi.org/10.1016/j.nanoen.2019.104335

ISO 25178 part 2, Geometrical Product Specification (GPS) - Surface Texture: Areal - Part 2: Terms, Definitions and Surface Texture Parameters, International Organization for Standartization, 2012.

K. Slámečka, D. Jech, L. Klakurková, S. Tkachenko, M. Remešová, P. Gejdoš, and L. Čelko, Thermal Cycling Damage in Pre-Oxidized Plasma-Sprayed MCrAlY + YSZ Thermal Barrier Coatings: Phenomenon Of Multiple Parallel Delamination of the TGO Layer, Surf. Coat. Technol., 2020, 384, p 125328. https://doi.org/10.1016/j.surfcoat.2019.125328

D.K. Owens and R.C. Wendt, Estimation of the Surface Free Energy of Polymers, J. Appl. Polym. Sci., 1969, 13(8), p 1741-1747. https://doi.org/10.1002/app.1969.070130815

J.M. Schuster, C.E. Schvezov, and M.R. Rosenberger, Analysis of the Results of Surface Free Energy Measurement of Ti6Al4V by Different Methods, Procedia Mater. Sci., 2015, 8, p 732-741. https://doi.org/10.1016/j.mspro.2015.04.130

G75-15 Standard Test Method for Determination of Slurry Abrasivity (Miller Number) and Slurry Abrasion Response of Materials (SAR Number), ASTM International, 2015. https://doi.org/10.1520/G0075-15

S. Al-Mutairi, M.S.J. Hashmi, B.S. Yilbas, and J. Stokes, Microstructural Characterization of HVOF/plasma Thermal Spray of Micro/Nano WC-12%Co powders, Surf. Coat. Technol., 2015, 264, p 175-186. https://doi.org/10.1016/j.surfcoat.2014.12.050

Q. Yang, T. Senda, and A. Ohmori, Effect of Carbide Grain Size on Microstructure and Sliding Wear Behavior of HVOF-Sprayed WC–12% Co Coatings, Wear, 2003, 254(1–2), p 23-34. https://doi.org/10.1016/S0043-1648(02)00294-6

M. Li and P.D. Christofides, Computational Study of Particle in-Flight Behavior in the HVOF Thermal Spray Process, Chem. Eng. Sci., 2006, 61(19), p 6540-6552. https://doi.org/10.1016/j.ces.2006.05.050

C.J. Li, A. Ohmori, and Y. Harada, Formation of an Amorphous Phase in Thermally Sprayed WC-Co, J. Therm. Spray Technol., 1996, 5, p 69-73. https://doi.org/10.1007/BF02647520

M. Federici, C. Menapace, A. Moscatelli, S. Gialanella, and G. Straffelini, Pin-on-Disc Study of a Friction Material Dry Sliding Against HVOF Coated Discs at Room Temperature and 300°C, Tribol. Int., 2017, 115, p 89-99. https://doi.org/10.1016/j.triboint.2017.05.030

S.M. Nahvi and M. Jafari, Microstructural and Mechanical Properties of Advanced HVOF-Sprayed WC-Based Cermet Coatings, Surf. Coat. Technol., 2016, 286, p 95-102. https://doi.org/10.1016/j.surfcoat.2015.12.016

X. Ding, X.D. Cheng, C. Li, X. Yu, Z.X. Ding, and C.Q. Yuan, Microstructure and Performance of Multi-Dimensional WC-CoCr Coating Sprayed by HVOF, Int. J. Adv. Manuf. Technol., 2018, 96, p 1625-1633. https://doi.org/10.1007/s00170-017-0837-5

R. Vaßen, G. Kerhoff, D. Stöver, Development of a micromechanical life prediction model for plasma sprayed thermal barrier coatings, Mat. Sci. and Eng.:A, 303 (1-2), p 100-109. https://doi.org/10.1016/S0921-5093(00)01853-0

W. Tillmann, L. Hagen, D. Stangier, M. Krabiell, P. Schröder, J. Tiller, C. Krumm, C. Sternemann, M. Paulus, and M. Elbers, Influence of Etching-Pretreatment on Nano-Grained WC-Co Surfaces and Properties of PVD/HVOF Duplex Coatings, Surf. Coat. Technol., 2019, 374, p 32-43. https://doi.org/10.1016/j.surfcoat.2019.05.054

P. Xu, G. Meng, L. Pershin, J. Mostaghimi, and T.W. Coyle, Control of the Hydrophobicity of Rare Earth Oxide Coatings Deposited by Solution Precursor Plasma Spray by Hydrocarbon Adsorption, J. Mat. Sci. Tech., 2021, 62, p 107-118. https://doi.org/10.1016/j.jmst.2020.04.044

J. Li, C. Li, G. Yan, and C. Li, Wettability Transition on Micro-Nano Hierarchical Structured Ni20Cr Coating Surface by Selective Spontaneous Adsorption During Vacuum Evacuation, Mater. Chem. Phys., 2018, 219, p 292-302. https://doi.org/10.1016/j.matchemphys.2018.08.049

M. Morra, E. Occhiello, R. Marola, F. Garbassi, P. Humphrey, and D. Johnson, On the Aging of Oxygen Plasma-Treated Polydimethylsiloxane Surfaces, J. Colloid Interface Sci., 1990, 137(1), p 11-24. https://doi.org/10.1016/0021-9797(90)90038-P

Acknowledgment

This research was made in the frame of the Specific Research Project CEITEC VUT-J-19-5799 awarded at the Central European Institute of Technology – Brno University of Technology. We acknowledge CzechNanoLab Research Infrastructure supported by MEYS CR (LM2018110). The help of Ing. Subhash Gupta within the XPS analysis is thankfully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (MP4 2679 kb)

Supplementary material 2 (MP4 1001 kb)

Rights and permissions

About this article

Cite this article

Komarov, P., Jech, D., Tkachenko, S. et al. Wetting Behavior of Wear-Resistant WC-Co-Cr Cermet Coatings Produced by HVOF: The Role of Chemical Composition and Surface Roughness. J Therm Spray Tech 30, 285–303 (2021). https://doi.org/10.1007/s11666-020-01130-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01130-6