Abstract

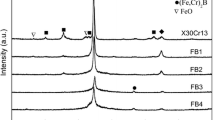

There is high demand for refurbishment of damaged mechanical components in power plants. Twin-wire arc spraying (TWAS) is promising for on-site proactive maintenance. In this paper, FeCr-based coating was prepared on AISI 1020 carbon steel substrate by TWAS. The coating microstructure was characterized in terms of porosity, oxides and constituent phases. The wear behavior of the coating was evaluated by ball-on-disk wear test at both room temperature (RT) and tube service temperature of 300 °C. The results show that the coating is characterized with composite-like structure of oxide boundaries and FeCr solid solution, with hard phase of borides embedded within FeCr phase, resulting an average microhardness of 10.80 GPa. Tested at RT and 300 °C, the weight loss of the coating indicates much better wear resistance than substrate steel. The morphology of the wear scars demonstrates that the wear mechanism of the coating transformed from furrow and fracture spalling at RT to adhesive and abrasive wear at high temperature. The high hardness and low oxidation rate of the coating contribute to excellent wear resistant. The FeCr-based coating by on-site TWAS has been successfully applied on boiler tubes, large-sized blades of slurry pumps and various fans.

Similar content being viewed by others

References

A. Skorek-Osikowska, L. Bartela, J. Kotowicz, and M. Job, Thermodynamic and Economic Analysis of the Different Variants of a Coal-Fired, 460 MW Power Plant Using Oxy-Combustion Technology, Energy Convers. Manag., 2013, 76, p 109-120

M. Gürtürk and H.F. Oztop, Exergy Analysis of a Circulating Fluidized Bed Boiler Cogeneration Power Plant, Energy Convers. Manag., 2016, 120, p 346-357

A. Arjunwadkar, P. Basu, and B. Acharya, A Review of Some Operation and Maintenance Issues of CFBC Boilers, Appl. Therm. Eng., 2016, 102, p 672-694

A.V. Levy, The Erosion-Corrosion of Tubing Steels in Combustion Boiler Environments, Corros. Sci., 1993, 35, p 1035-1043

E. Huttunen-Saarivirta, H. Kinnunen, J. Tuiremo, M. Uusitalo, and M. Antonov, Erosive Wear of Boiler Steels by Sand and Ash, Wear, 2014, 317(1), p 213-224

J. Ahmad, J. Purbolaksono, L.C. Beng, A.Z. Rashid, A. Khinani, and A.A. Ali, Failure Investigation on Rear Water Wall Tube of Boiler, Eng Failure Anal, 2009, 16(7), p 2325-2332

B.A. Lindsley, A.R. Marder, and J.J. Lewnard, The Effect of Circulating Fluidized Bed Particle Characteristics on Erosion of 1020 Carbon Steel, Wear, 1995, 188, p 33-39

X. Li, S. Chen, H. Ding, Z. Huang, B. Liu, M. Fang, Y.G. Liu, X. Wu, and B. Ma, Abrasive Wear Behavior of SiCp-Sialon Composite Refractories, Ceram. Int., 2015, 41(7), p 9146-9151

H.P. Chen, Y.Q. Shen, X.H. Wang, X.M. Dai, H.Y. Xue, D.C. Liu, Advanced refractory and anti-wearing technology of cyclone separator in CFB boiler. in Proceedings of the 20th International Conference on Fluidized Bed Combustion, ed. by G. Yue, H. Zhang, C. Zhao, Z. Luo (Berlin, Heidelberg, 2010), pp 247–249

K. Prasad, V.G. Kadirvell, L.N. Satapathy, and R. Sanakaranarayana, High Temperature Erosion of Dense Refractory Castables for CFBC Boilers, Int. Ceram Rev., 2017, 66(1), p 24-29

Y. Xia, L. Cheng, R. Huang, L. Xu, Q. Wang, and Z. Luo, Anti-wear Beam Effects on Water Wall Wear in a CFB Boiler, Fuel, 2016, 181, p 1179-1183

R. Li, Z. Zhou, D. He, L. Zhao, and X. Song, Microstructure and High-Temperature Oxidation Behavior of Wire-Arc Sprayed Fe-Based Coatings, Surf. Coat. Technol., 2014, 251, p 186-190

V.I. Pokhmurskii, M. Student, V. Gvozdeckii, T. Stypnutskyy, O. Student, B. Wielage, and H. Pokhmurska, Arc-Sprayed Iron-Based Coatings for Erosion-Corrosion Protection of Boiler Tubes at Elevated Temperatures, J. Therm. Spray Technol., 2013, 22(5), p 808-819

E. Qin, Q. Huang, Y. Shao, G. Chen, L. Ye, Q. Gu, and S. Wu, The Characterization of Twin-Wire Arc-Sprayed FeCrBSi Coating and the Application in Sewage Sludge Boilers, J. Therm. Spray Technol., 2014, 23(8), p 1493-1498

K. Venugopal and M. Agrawal, Evaluation of arc Sprayed Coatings for Erosion Protection of Tubes in Atmospheric Fluidised Bed Combustion (AFBC) Boilers, Wear, 2008, 264(1), p 139-145

N. Yuksel and S. Şahin, Wear Behavior–Hardness–Microstructure Relation of Fe-Cr-C and Fe-Cr-C-B Based Hardfacing Alloys, Mater. Des., 2014, 58, p 491-498

H. So, D.S. Yu, and C.Y. Chuang, Formation and Wear Mechanism of Tribo-Oxides and the Regime of Oxidational Wear of Steel, Wear, 2002, 253(9), p 1004-1015

Q. Yang, T. Senda, N. Kotani, and A. Hirose, Sliding Wear Behavior and Tribofilm Formation of Ceramics at High Temperatures, Surf. Coat. Technol., 2004, 184(2), p 270-277

A. Jafari, K. Dehghani, K. Bahaaddini, and R. Abbasi Hataie, Experimental Comparison of Abrasive and Erosive Wear Characteristics of Four Wear-Resistant Steels, Wear, 2018, 416–417, p 14-26

L.J. da Silva, C.J. Scheuer, and A.S.C.M. D’Oliveira, Effect of Microstructure on Wear Performance of NiCrSiBC Coatings, Wear, 2019, 428–429, p 387-394

Acknowledgments

Financial support from Suzhou Science and Technology Program (SGC201720) is acknowledged. The authors thank Mr. Kejiang Song, Mr. Anqiang Zhu for assistance in sample preparation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited paper selected from presentations at the 10th Asian Thermal Spray Conference (ATSC 2020) and has been expanded from the original presentation. ATSC 2020 was held in Ningbo, China, from November 1-3, 2020, and was organized by the Asian Thermal Spray Society with Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences as the Host Organizer.

Rights and permissions

About this article

Cite this article

Liu, C., Lu, H., Qin, E. et al. The FeCr-Based Coating by On-Site Twin-Wire Arc Spraying for Proactive Maintenance of Power Plant Components. J Therm Spray Tech 30, 959–967 (2021). https://doi.org/10.1007/s11666-020-01138-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01138-y