Abstract

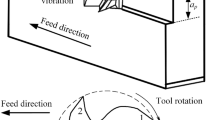

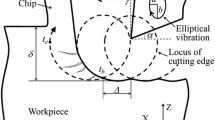

Ultrasonic elliptical vibration-assisted machining (UEAM) and laser-assisted machining (LAM) are considered as hybrid machining processes, in which 2D ultrasonic vibrations and heat are used to improve metal cutting process; in the present study, a series of experimental tests with the aim of measuring cutting forces and workpiece surface roughness in hybrid laser- and ultrasonic elliptical vibration-assisted machining (HL-UEAM) are conducted to evaluate the effect of process parameters including un-deformed chip temperature, vibration amplitude, work velocity and feed. A statistical analysis has been performed on the data obtained from the experiments, and the main effect of parameters as well as their interaction effects on process outputs is analyzed. The results revealed the reductions of 43, 54 and 75% in the main component of cutting force can be achieved in LAM, UEAM and HL-UEAM compared to conventional turning (CT), respectively. Therefore, from the force reduction perspective, simultaneous application of laser and ultrasonic elliptical vibrations would be more effective than their separate usage. The results of surface roughness measurement declared the approximately 20% increase in surface roughness by UEAM compared to CT. However, HL-UEAM surface roughness measurement shows approximately 35% enhancement compared to CT.

Similar content being viewed by others

References

Lauwers B (2011) Surface integrity in hybrid machining processes. Proced Eng 19:241–251. https://doi.org/10.1016/j.proeng.2011.11.107

Moriwaki T, Shamoto E (1994) Ultrasonic elliptical vibration cutting. CIRP Ann Manuf Technol 44:31–34. https://doi.org/10.1016/S0007-8506(07)62269-0

Shamoto E, Moriwaki T (1999) Ultraprecision diamond cutting of hardened steel by applying elliptical vibration cutting. CIRP Ann Manuf Technol 48:441–444. https://doi.org/10.1016/S0007-8506(07)63222-3

Ma C, Shamoto E, Moriwaki T, Wang L (2004) Study of machining accuracy in ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 44:1305–1310. https://doi.org/10.1016/j.ijmachtools.2004.04.014

Guo P, Ehmann KF (2011) Development of a new vibrator for elliptical vibration texturing. ASME Conf Proc. https://doi.org/10.1115/MSEC2011-50131

Zhou M, Hu L (2015) Development of an innovative device for ultrasonic elliptical vibration cutting. Ultrasonics 60:76–81. https://doi.org/10.1016/j.ultras.2015.02.015

Wang Q, Wu Y, Gu J, Lu D, Ji Y, Namura M (2016) Fundamental machining characteristics of the in-base-plane ultrasonic elliptical vibration assisted turning of inconel 718. Procedia CIRP 42:858–862. https://doi.org/10.1016/j.procir.2016.03.008

Liu J, Jiang X, Han X, Gao Z (2018) Effects of rotary ultrasonic elliptical machining for side milling on the surface integrity of Ti-6Al-4V. Int J Adv Manuf Technol 101:1451–1465. https://doi.org/10.1007/s00170-018-2847-3

Zhang C (2018) Study on the cutting force in elliptical ultrasonic vibration cutting. In: Xhafa F, Patnaik S, Tavana M (Eds.) International conference on intelligent and interactive systems and applications, Hong Kong, China Springer: Cham 1137–1142. https://doi.org/10.1007/978-3-030-02804-6_147

Tan R, Zhao X, Zhang S, Zou X, Guo S (2019) Study on ultra-precision processing of Ti-6Al-4V with different ultrasonic vibration-assisted cutting modes. Mater Manuf Process 34:1380–1388. https://doi.org/10.1080/10426914.2019.1660788

Khajehzadeh M, Razfar MR (2020) Process parameters influence on laser-assisted machining-induced residual stresses. Mater Manuf Process. https://doi.org/10.1080/10426914.2020.1784930

Hsu CY, Huang CK, Wu CY (2007) Milling of MAR-M247 nickel-based superalloy with high temperature and ultrasonic aiding. Int J Adv Manuf Technol 34:857–866. https://doi.org/10.1007/s00170-006-0657-5

Elhami S, Razfar MR, Farahnakian M (2015) Analytical, numerical and experimental study of cutting force during thermally enhanced ultrasonic assisted milling of hardened AISI 4140. Int J Mech Sci 103:158–171. https://doi.org/10.1016/j.ijmecsci.2015.09.007

Muhammad R, Ahmed N, Ullah H, Roy A, Silberschmidt VV (2018) Hybrid machining process: experimental and numerical analysis of hot ultrasonically assisted turning. Int J Adv Manuf Technol 97:2173–2192. https://doi.org/10.1007/s00170-018-2087-6

Sofuoğlu MA, Çakır FH, Gürgen S, Orak S, Kuşhan MC (2018) Numerical investigation of hot ultrasonic assisted turning of aviation alloys. J Braz Soc Mech Sci Eng 40:122. https://doi.org/10.1007/s40430-018-1037-4

Sofuoğlu MA, Çakır FH, Gürgen S, Orak S, Kuşhan MC (2018) Experimental investigation of machining characteristics and chatter stability for Hastelloy-X with ultrasonic and hot turning. Int J Adv Manuf Technol 95(1–4):83–97. https://doi.org/10.1007/s00170-017-1153-9

Gürgen S, Çakır FH, Sofuoğlu MA, Orak S, Kuşhan MC, Li H (2019) Multi-criteria decision-making analysis of different non-traditional machining operations of Ti6Al4V. Soft Comput 23(13):5259–5272. https://doi.org/10.1007/s00500-019-03959-8

Jiao F, Niu Y, Zhang MJ, Zhang CJ (2016) Research on characteristics of tool wear in laser heating and ultrasonic vibration cutting of tungsten carbide. Adv Mech Eng 8:1687814016679786. https://doi.org/10.1177/1687814016679786

Jiao F, Niu Y, Zhang M (2018) Prediction of machining dimension in laser heating and ultrasonic vibration composite assisted cutting of tungsten carbide. J Adv Manuf Syst 17:35–45. https://doi.org/10.1142/S0219686718500038

Jiao F, Zhang MJ, Niu Y (2019) Optimization of tungsten carbide processing parameters for laser heating and ultrasonic vibration composite assisted cutting. Proc Inst Mech Eng Part C J Mech Eng Sci 233:4140–4153. https://doi.org/10.1177/0954406218809123

Zerilli FJ, Armstrong RW (1987) Dislocation-mechanics-based constitutive relations for material dynamics calculations. J Appl Phys 61:1816–1825. https://doi.org/10.1063/1.338024

Khajehzadeh M, Akhlaghi M, Razfar MR (2014) Finite element simulation and experimental investigation of tool temperature during ultrasonically assisted turning of aerospace aluminum using multicoated carbide inserts. Int J Adv Manuf Technol 75:1163–1175. https://doi.org/10.1007/s00170-014-6163-2

Montgomery DC (2017) Design and analysis of experiments, 10th edn. John Wiley, New York

Fernández-Abia AI, Barreiro J, López de Lacalle LN, Martínez S (2011) Effect of very high cutting speeds on shearing, cutting forces and roughness in dry turning of austenitic stainless steels. Int J Adv Manuf Technol 57:61–71. https://doi.org/10.1007/s00170-011-3267-9

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Adriano Fagali de Souza.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khajehzadeh, M., Ahmadpoor, S.S., Rohani Raftar, O. et al. Process parameters influence on cutting force and surface roughness during hybrid laser- and ultrasonic elliptical vibration-assisted machining. J Braz. Soc. Mech. Sci. Eng. 43, 32 (2021). https://doi.org/10.1007/s40430-020-02751-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02751-2